Erosion is an entirely natural process; however, when left to its own, it can have extremely damaging effects on landscapes, […]

LLDPE Geomembranes is just one of numerous suppliers and producers of LLDPE geomembranes in China. The flexibility and strength of LLDPE Geomembranes far exceed the industry standard, along with that of the workmanship imparted into these products. LLDPE Geomembranes ensures complete customer satisfaction, hence the company’s operational efficiency. For well-known yet ever-changing applications and solutions, it would be best to rely on LLDPE Geomembranes with a special orientation toward a specially defined requirement or desire.

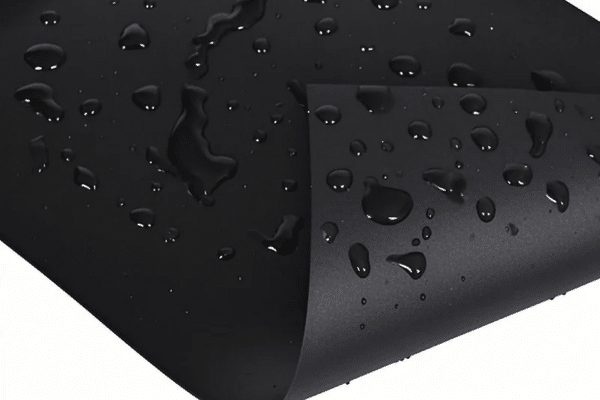

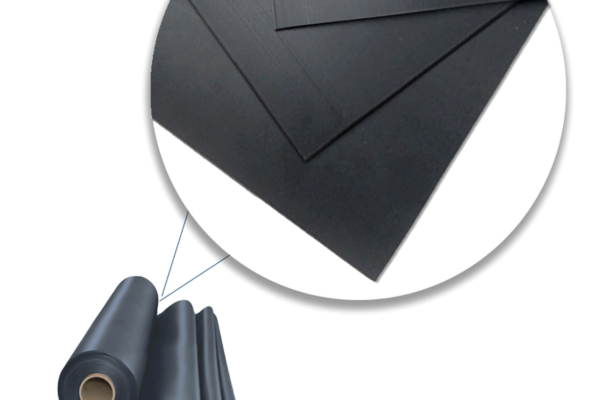

Geomembranes made from LLDPE or linear low density polyethylene materials are flexible, tough synthetic substances. An LLDPE membrane acts as a barrier against seepage of any kind-liquid, gas, or contamination. Because of their high chemical resistivity and ability to adapt-are used extensively in landfills, ponds, and mining.

Woven geotextiles have the key advantages of high strength, good stability, and versatility, making them suitable for various applications. They are able to effectively reinforce the soil and provide good long-term performance.

LLDPE geomembranes offer superior flexibility, enabling easy installation and adaptation to uneven surfaces.

They provide excellent resistance to a wide range of chemicals, ensuring long-term performance in harsh environments.

These geomembranes exhibit robust durability, withstanding mechanical stress and environmental degradation effectively.

LLDPE geomembranes feature strong, reliable seams, enhancing overall integrity and containment efficiency.

Manufactured from flexible linear low-density polyethylene, this thin LLDPE geomembrane offers excellent adaptability for small-scale containment projects. Known for its ease of installation, it is primarily used for temporary linings, secondary containment, and light-duty applications where moderate flexibility is required.

Crafted from durable LLDPE, this geomembrane provides enhanced strength and flexibility for medium-duty applications. It is commonly employed in pond liners, irrigation canals, and landfill caps, offering reliable seepage prevention and chemical resistance.

This LLDPE geomembrane, made from robust linear low-density polyethylene, delivers a balance of flexibility and durability. It is widely used in aquaculture ponds, wastewater treatment lagoons, and mining heap leach pads, ensuring effective containment and longevity.

Manufactured with high-quality LLDPE, this thicker geomembrane offers superior puncture resistance and chemical stability. It is ideal for heavy-duty applications such as landfill liners, large reservoirs, and industrial containment, providing strong performance under stress.

Constructed from resilient LLDPE, this geomembrane provides exceptional tensile strength and durability. It is commonly utilized in large-scale projects like municipal solid waste landfills, mining operations, and water storage systems, ensuring long-term environmental protection.

Made from premium linear low-density polyethylene, this thickest LLDPE geomembrane offers maximum strength and resistance to harsh conditions. It is primarily used in critical applications such as hazardous waste containment, deep mining liners, and high-pressure liquid storage, guaranteeing robust performance.

| Parameter Name | Example Value | Units | Notes / Description |

|---|---|---|---|

| Tensile Strength (MD / Warp) | 80 | kN/m | Ultimate Strength in Machine Direction |

| 5400 | lbs/ft | ||

| Tensile Strength (CD / Weft) | 75 | kN/m | Ultimate Strength in Cross Direction |

| 5075 | lbs/ft | ||

| Elongation (MD / Warp) | 20 | % | % Strain at Break in Machine Direction |

| Elongation (CD / Weft) | 25 | % | % Strain at Break in Cross Direction |

| CBR Puncture Resistance | 2500 | N | Resistance to localized puncture load (e.g., from aggregate) |

| 562 | lbs | ||

| Apparent Opening Size (AOS) | 0.4 | mm | Max particle size retained (0%) - e.g., Sieve No. 40 |

| Permittivity | 0.45 | s⁻¹ | Water flow rate perpendicular to plane |

| Mass Per Unit Area | 300 | g/m2 | Weight of the fabric |

| 8.9 | oz/yd2 | ||

| Material Type | LLDPE | N/A | Polymer used for the fabric |

| UV Resistance (500 hrs) | 85 | % Retained | Minimum % strength retained after standard UV exposure |

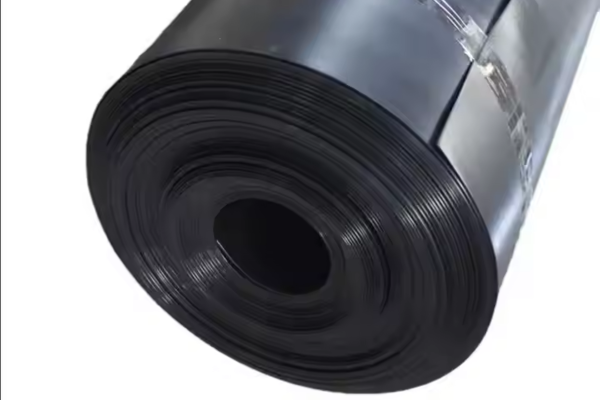

| Roll Width | 5 | m | Standard roll width |

| 16.4 | ft | ||

| Roll Length | 150 | m | Standard roll length |

| 492 | ft |

Cost Efficiency: Sourcing directly from our production facility reduces overhead, offering competitive and budget-friendly pricing.

High Durability: On-site manufacturing ensures meticulous standards, delivering LLDPE geomembranes with exceptional strength and longevity.

Customized Solutions: As producers, we provide customizable options, adapting fabrics to meet unique project demands effectively.

Rapid Turnaround: In-house processing eliminates external delays, ensuring prompt production and shipping.

Technical Expertise: Our team offers professional advice and employs cutting-edge methods to enhance geomembrane performance.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

LLDPE (linear low-density polyethylene) liners are more flexible and adaptable due to their lower density, making them suitable for applications requiring conformity to uneven surfaces. HDPE (high-density polyethylene) liners, with higher density, offer greater tensile strength and chemical resistance, ideal for heavy-duty containment projects. LLDPE liners are less rigid but more puncture-resistant, while HDPE liners provide superior longevity under harsh conditions.

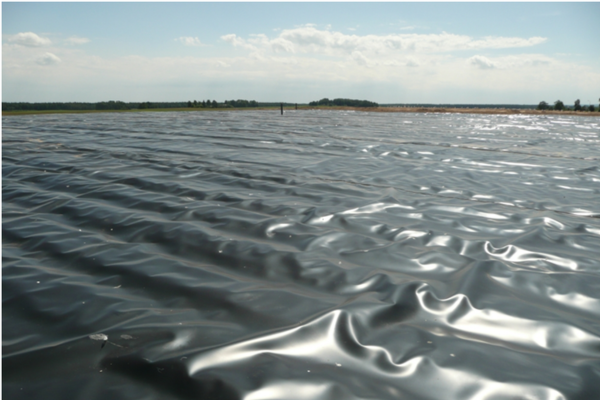

LLDPE geomembranes are utilized in applications such as landfill liners, aquaculture ponds, water reservoirs, and mining heap leach pads. Their flexibility, chemical resistance, and impermeability make them effective for containment and environmental protection in diverse civil and industrial projects.

Yes, LLDPE is an excellent pond liner due to its flexibility, which allows it to conform to irregular terrains, and its resistance to UV degradation and chemicals, ensuring long-term water retention and protection for aquaculture or decorative purposes.

LLDPE geomembranes exhibit high durability, withstanding mechanical stress, puncture loads, and environmental factors such as UV exposure and chemical exposure when properly installed and maintained, typically lasting 20 to 30 years or more.

An LLDPE pond liner generally lasts 20 to 30 years under optimal conditions, with potential extension beyond 30 years if protected from excessive UV radiation and mechanical damage, depending on site-specific factors and maintenance practices.

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Erosion is an entirely natural process; however, when left to its own, it can have extremely damaging effects on landscapes, […]

Geomembrane liners are used in different industries but their major role is to prevent leakage as a barrier for which […]

The very first consideration when talking about the protection of water storage facilities is by which materials the whole thing […]

Maintaining sanitary practices and managing waste systems is crucial for sustaining the health and life of communities and the environment. […]

With the evolution of parking solutions, traditional paved lots merely ceased to be the sole option. Permeable grass parking has […]

Weeds, gardeners and landscapers’ constant trouble, not only take over the outdoor space but also depril the plants of the […]

Taking care of young trees is very important to nurture a healthy and thriving outdoor space. But, when the bark […]

Once weeds have entered your garden or yard, they immediately take hold and make maintenance distressingly difficult as if they […]

Build resilient and sustainable infrastructure using LLDPE Geomembranes. These innovative, flexible liners provide critical impermeable containment, high chemical resistance as well as seepage control for landfills, water reservoirs, and mining activities. Guarantee reliability and durability in harsh environmental conditions. These challenges are resolved using proven technology. Visit us today to request a quote or check our catalog for LLDPE Geomembranes.

A:An LLDPE geomembrane is a liner made from linear low-density polyethylene, offering a flexible and impermeable barrier designed to prevent the seepage of liquids, gases, or contaminants in environmental and civil engineering projects.

A: LLDPE geomembranes are used in landfill liners, aquaculture ponds, water reservoirs, mining heap leach pads, and wastewater treatment lagoons, providing effective containment and environmental protection.

A: The thickness of an LLDPE geomembrane typically ranges from 0.5 mm (20 mil) to 2.5 mm (100 mil), with the specific thickness selected based on project requirements such as flexibility and load-bearing capacity.

A: The life expectancy of an LLDPE geomembrane is approximately 20 to 30 years under optimal conditions, with potential extension to 40 years or more when protected from UV radiation and mechanical damage.

A: LLDPE geomembranes are more flexible and easier to install than HDPE geomembranes, which offer greater tensile strength and chemical resistance, making HDPE suitable for heavier-duty applications.

A: When selecting an LLDPE geomembrane, consider thickness, chemical compatibility, UV resistance, installation conditions, and compliance with standards such as ASTM D6392 to ensure optimal performance.

A:

LLDPE geomembranes are manufactured through a process involving the extrusion of linear low-density polyethylene resin into thin sheets, followed by cooling and quality control checks. This method ensures uniformity, flexibility, and strength, meeting industry standards for containment applications.

A: LLDPE geomembrane contributes to environmental protection by preventing the leakage of hazardous substances into soil and groundwater, supporting sustainable waste management and safeguarding ecosystems in containment projects.