Leading the array of textiles is polypropylene fabric eulogizing versatility, durability, and sustainability, all considered apart from other materials. With clothing, medical supplies, and industrial applications being in its domain, the innovative fabric has impacted plenty of industries through its unique features. In this article, we will delve into everything concerning polypropylene fabric, from its remarkable features and applications to the reasons driving its skyrocketing popularity. Come along as we embrace what makes this material so imperative in today’s fast-evolving world and the increasing acceptability that consumers and manufacturers alike grant it.

Introduction to Polypropylene Fabric

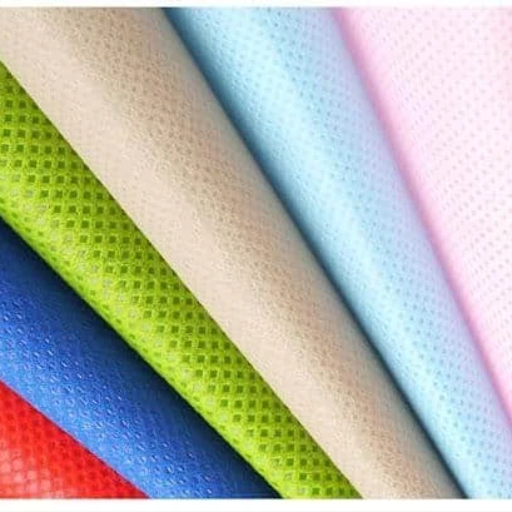

Polypropylene fabric is a synthetic material formed by polymerizing propylene. Very lightweight and durable, and also resistant to moisture, it finds use in applications from reusable bags to activewear, from medical masks to packaging. Polypropylene is popular on both the consumer and industrial fronts because of its cost-effectiveness and recyclability.

What Is Polypropylene Fabric?

Polypropylene fabric is a kind of textile created from polypropylene, a thermoplastic polymer derived from propylene gas polymerization. This fine material is known for being adaptable and is made lighter in weight and stronger to be used across industries because it is cheap, strong, and considered environmentally friendly.

Water repelling, resisting chemicals and stains, is what places polypropylene in the category of having multipurpose usage with outdoor applications and in products requiring long-term resilience. As per the latest data, polypropylene counted for approximately 16% of total plastic production tracer in 2022, truly making it one of the more widely used thermoplastics in the world.

Polypropylene fabric implementation includes extensive application in reusable items such as tote bags for decreasing the number of single-use plastics. Other uses include masks made from medical ratification qualities that filter well and repel water; automotive textiles, upholstery, performance wear, ropes, and food packaging.

Recyclability becomes a huge factor adding significantly to the reputation of being eco-friendly. Studies conclude that enhanced recycling technology for polypropylene, such as pyrolysis and depolymerization, enable better recovery, thereby reducing waste and enhancing circular economy principles in the textile and plastic industries.

Why is Polypropylene Popular?

Polypropylene’s properties made it widely used all over the world because it is versatile, cheap, and also adaptable in a wide range of applications. According to the latest data, around 20% of global plastic production is made up of polypropylene, reinforcing its instant usage by industries worldwide. Since it is very lightweight, strong, resistant to chemicals, and affordable, its popularity has been highlighted.

Industries love using lot of polypropylene as it is durable and can stay strong during extreme conditions. For instance, because of its melting point being about between 130 to 170 degrees centigrade, it is ideal for use in food containers and automotive parts. Besides, being water-resistant gives another edge to being used for medical grade fabrics and outdoor furniture.

Key to strengthening the popularity of polypropylene is the potential of sustainability. Global efforts to reduce plastic waste have also encouraged innovations on recycling with advancements being led by polypropylene. Reports from recent years indicate that newer, more sophisticated approaches to recycling, including various chemical recycling techniques, may soon be able to directly convert polypropylene waste back into raw material for reuse, thereby opening new avenues for sustainability. This, combined with the adaptable nature of polypropylene for newer technologies, would keep the material highly relevant for new industries.

Overview of Applications

Polypropylene continues to be a crucial material in various industries due to its versatility, durability, and ability to adapt to new technologies. It was estimated that, in 2022, the dollar size of the global polypropylene market was approximately $126 billion and that it could grow toward an approximate value of $170 billion by 2027 at a CAGR of 5.7%, thanks to its numerous applications in packaging, automotive, construction, and medical fields.

Packaging Field

The packaging industry is one of the biggest markets for polypropylene with almost 35% of the total global demand for polypropylene being met by this industry. Food containers, films, and caps are molded from polypropylene because it’s light and resistant to moisture. Biodegradable polypropylene composites for eco-friendly packaging are the next frontier in this line, thus creating additional opportunities for its demand.

Automobile Application

Another industry that considers itself highly dependent on polypropylene is the automobile industry, where it is the main material for the manufacture of bumpers, interior panels, and dashboard components. The second best in respect to high temperature resistance and impact stress, the property that has been the driving force for the usage in these applications is. It is revealed that lightweight polypropylene parts can reduce the vehicle weight by 10% which favors fuel efficiency and reduction of carbon emissions.

Medical and Healthcare Industries

Medical applications of polypropylene are growing rapidly since polypropylene is non-toxic to humans and able to resist chemicals. It is used for making syringes, medical vials, and surgical instruments. During the COVID-19 pandemic, polypropylene became the base material for N95 masks and PPEs, causing its demand to skyrocket.

Such applications emphasize how polypropylene is a key player in facilitating sustainable and efficient solutions for these industries.

Properties and Characteristics of Polypropylene Fabric

Polypropylene fabric is considered lightweight and tough, while resisting moisture, chemicals, and stains. It also exhibits excellent tensile strength in most cases-that is, suitable for applications in heavy duty. The polypropylene permits air flow and dries swiftly, allowing for maximum comfort if worn for clothing or protective gear. Polypropylene does resist fading and abrasion, ensuring a long service life in other, varied applications.

Advanced Fabric Characteristics of Polypropylene

Polypropylene fabric comes with a unique combination of advanced properties, which translates into an extremely versatile material for industrial purposes. One interesting characteristic of the fabric lies in its low density, given that polypropylene stands among one of the lightest synthetic fibers with an approximate density of 0.91 g/cm³, allowing the easy production of lightweight yet sturdy products. Another critical feature is craftsmanship-level tensile strength that averages from 30 to 40 MPa, providing its greatness to withstand application of heavy stress without cracking, which is typical for industrial and outdoor uses.

Polypropylene also behaves very well with chemical resistance, especially to acids, alkalies, and organic solvents. It thus remains well in nasty environments, being appropriate for chemical storage or laboratory uses. Repellent to moisture, with water absorption less than 0.01%, the fabric guarantees superb performance in working damp, so growth of mold or mildew is deterred.

Another prominent characteristic that makes this polymer a good choice is its breathability along with fast drying. For these reasons, it is widely utilized in making sportswear, outdoor apparel, and medical textiles. Also, the thermal insulation properties supported by regulating body temperature during temperature extremes grant comfortable wearability across various climates. An additional benefit relevant for certain thermal uses is that polypropylene will withstand a temperature of up to 100–110°C.

Ideally considered sustainable, PP fabric has been demonstrated to be 100% recyclable, thus awarding it respect as an eco-friendly option. Recent technological transformations in the production process attest to energy saving and reduction of waste.

These characteristics, substantiated by credible data and recent innovations, explain the increasing role polypropylene has in acknowledging durable, practical, and sustainable materials.

Benefits of Polypropylene Application

Due to its superb qualities and versatility, polypropylene is increasingly chosen by different industries around the world. Data show that the global polypropylene market size was approximately valued at $119.84 billion at the end of 2022, and this would continue to expand with 5.5% CAGR over 2023–2030 as a result of its utilization in packaging, automotive parts, textiles, and medical applications.

In extremely harsh environments, a prime feature of polypropylene will come into play: resistance to chemical corrosion. Also, it is very lightweight and easy to handle with application in industries for the sake of energy conservation, most notably the automotive and construction industries. Polypropylene applications in vehicle manufacture, for instance, help automobile manufacturers uplift the fuel efficiency by minimizing gross vehicle weight.

An environmentally friendly consideration is that polypropylene is 100% recyclable, reducing its impact on the environment. The material can be remelted and reused a maximum of four times before it starts deteriorating, which makes it an ideal option for fulfillment of sustainability goals throughout the globe. Studies have also revealed that recycling polypropylene takes 88% less energy than manufacturing virgin plastic, meaning that its recycling helps reduce energy consumption.

These are points showing polypropylene as an emerging key player in creating a sustainable and cheap future across industries. Its advancement and further increase in acceptance speak louder for the delicate logic of combining durability, practicality, and environmental protection.

Types of Polypropylene Fabric

Polypropylene fabrics are typically classified into woven, non-woven, and spunbond types.

| Type | Structure | Features | Uses | Durability |

|---|---|---|---|---|

| Woven | Interlaced | Strong, Firm | Bags, Covers | Long-Lasting |

| Non-Woven | Bonded Fibers | Soft, Light | Medical, Masks | Moderate |

| Spunbond | Continuous | Lightweight | Filters, Geotextiles | Durable |

Common Uses of Polypropylene Fabric

Because it is such a versatile material, polypropylene fabric has a multitude of industrial uses. The common uses include reusable shopping bags, because of its strength and water resistance. Other applications include various medical usages, such as surgical masks, gowns, and disposable hygiene products due to the fabric’s lightweight and breathable attributes. The fabric is further used for geotextiles and agricultural sheets because of its strength and resistance to moisture and chemical attacks. All these factors place polypropylene among the top choices both in day-to-day usage and special industrial applications.

Polypropylene in the Textile Industry

Lately, polypropylene has gained increased attention in the textile industry because of its interesting attributes and the versatility it offers. Being lightweight, water-resistant, and exceptionally durable, it enters into all uses where preference is given to functionality rather than looks. What really puts polypropylene way above the rest is its ability to wick moisture; hence, it is a perfect material for activewear and sportswear. Unlike a regular fabric that absorbs water through capillary action, polypropylene lets it flow free; hence, this keeps the wearer dry and very comfortable through physical exertion.

In addition, polypropylene textiles offer excellent thermal resistance and decent breathability, aiding the insulation of substances at different temperatures. It validates their use as materials for several outdoor gears such as insulated jackets, rucksacks, and camping equipment. Recent industry reports disclosed that the global polypropylene fiber market is expected to reach about $41.4 billion in 2032 with demand being increased in domains like sports textiles, furniture, and automotive interior.

In fact, polypropylene is winning stakes in the sustainable fashion front as well. It is fully recyclable and requires less energy input to be made than quite a few other synthetic fibers-more environment-friendly therefore. Newly developed processes are enabling textile mills to produce polypropylene fabrics of a better grade with improved softness and flexibility, which in turn will increase its applications in clothing and textiles.

Through strength, lightweight nature, and recyclability, polypropylene upholds the modern textile market’s needs for both practical and sustainable materials.

Packaging Applications

In packaging, polypropylene assumes a crucial role because of its multipurpose properties and being so cost-effective. Naturally, being light, it helps cut transportation costs. It further accomplishes these objectives by protecting the products during handling and shipment. Market data disclose that the global polypropylene packaging market was valued at about $130 billion in 2022 and is predicted to grow at a CAGR of 5.2% from 2023 to 2030. This is basically driven by growing demands for flexible packaging solutions, especially within the food and beverage industry, wherein polypropylene-based flexible films, containers, and bottle caps are produced.

Also, having great resistance to moisture and airtight sealing properties makes it an excellent material to be used for food packaging applications, wherein retention of freshness is desired. Endless research for strengthening innovative bio-based alternatives to polypropylene fits well into sustainable packaging targets since many companies wish to achieve the ‘green’ criteria to lessen the adverse impact of plastic waste. With innovation and elevation in application, polypropylene continues to take the center stage in packaging lay-out throughout all industries.

Uses of Polypropylene in Construction

Polypropylene is considered one of the best materials in the construction industry for the durability of its construction and the versatility of its application. Polypropylene is first used for making geotextiles required for stabilizing soil, erosion control, and drainage in different civil engineering projects. A reputed report states that the world geotextile market is worth $8.2 billion as of 2023, with polypropylene-based materials consuming a good chunk of the valuation because of their lightweight properties and resistance to chemicals and microorganisms.

The fibers from polypropylene also are being used widely in specific concrete mixes to increase tensile strength and reduce cracking, especially in conditions under which high stress or temperature fluctuations are applied to it. In the construction field, polypropylene-based insulation and piping systems are preferred because the material exhibits excellent thermal resistance while at the same time absorbing very little moisture. With this construction market projected to grow at a CAGR of 6% between 2023 and 2030, those demands for polypropylene goods will rise even further, turning it into a central figure in the modern infrastructure development.

Environmental Considerations

Polypropylene is said to be an environmentally friendly material when compared to other plastics since it is recyclable, lightweight, and offers smaller carbon footprints in its production. Being a plastic, however, it may cause environmental pollution if mishandled. Recycling plants need to be made capable of handling polypropylene, and proper disposal measures must be advised widely to insist upon minimizing its environmental impact.

Sustainability of Polypropylene Materials

Due to its wide applications and recyclability, polypropylene has caught attention as a sustaining material. Also, a major contributing factor to sustainability is that it requires low energy consumption during manufacture. Recent studies have disclosed that polypropylene production uses about 73.4 MJ/kg of energy, less than other common plastics such as polyethylene terephthalate (PET) and polycarbonate. In addition, less greenhouse gas is emitted from a polypropylenes lifecycle, at the amount of around 1.4 kg CO₂ emitted per kilogram during the manufacturing stage, much less than various alternatives heavy on carbon emissions.

Another benefit of polypropylene is recycling options. Polypropylene, also identified as #5 plastic, is witnessing improvements in recycling technologies that promote its recovery. These changes have witnessed a steady increase in polypropylene recycling programs in many regions, reporting recycling rates of around 10% globally. Besides recycling, systems like chemical recycling, which recently opened, allow for polypropylene to be chemically broken down at the molecular level for reuse, giving a closed-loop approach to enhancing its lifecycle sustainability.

Although things are getting better, many hurdles still exist today: Polytechnic can still end up in the environment because of mismanagement of waste, especially in places that do not have any chances to separate these recyclable products. If polypropylene is disposed of incorrectly, it would in no time become an urgent matter of marine pollution and microplastic contamination. Collaboration on public awareness campaigns, more investment into recycling technologies, and policies that promote the use of recycled polypropylene for manufacturing can be the way out of dealing with these issues. Once this is done, polypropylene will be at the forefront of sustainable design.

Recycling and Disposal of Polypropylene Fabric

The recycling of polypropylene fabric is essential for lessening environmental impact and fostering sustainability. Being thermoplastic polymers, polypropylenes can be highly recycled and processed into new products many times without any considerable loss of property. The recent reports suggest that only about 1% of polypropylene is recycled worldwide, revealing the pressing need to enhance recycling rates.

Mechanical recycling of polypropylene fabric is deemed to be one of the best recycling methods. The fabric recycled mechanically is cleaned, shredded, melted, and shaped into pellets that are usable once more. Alternative technologies such as chemical recycling continue to develop and break down polypropylene into its original monomers for the manufacture of high-quality raw materials. While sorting and contamination remain major obstacles affecting any recycling procedure, both mechanical and chemical methods stand true in their efficiency Declaration.

Every attempt should be made to dispose of polypropylene in ways that do not cause environmental impact if recycling is impossible. Left for landfills, polypropylene fabrics would be present for several decades, which is a time generally perceived as sufficient for landfill filling. Incineration constitutes another disposal method, but in this case, controlled incinerators with adequate emission treatment mechanisms should be used to prevent any hazardous substances being released into the atmosphere.

These efforts are supported by regulators and industry with policies that promote extended producer responsibility (EPR) and investment into advanced recycling infrastructure. For example, stringent measures are introduced by the European Union to ensure the recycling of at least 55% by weight of all plastics by 2030, which sets a direct influence in managing polypropylene.

The responsibility for improving responsible disposal habits on the consumer side falls upon the consumers checking their local recycling rules and ensuring that they can recycle the fabric when clean and free from contaminants. Given the newest developments and a combined effort, the future of polypropylene fabric would have more responsible management and can thus contribute to a circular economy and setting down its carbon footprint at the same time.

Comparing Polypropylene with Polyester

Polypropylene and polyester differ in weight, durability, moisture resistance, cost, recycling potential, and applications.

| Parameter | Polypropylene | Polyester |

|---|---|---|

| Weight | Lightweight | Heavier |

| Durability | Less durable | Durable |

| Moisture | Resistant | Absorbent |

| Cost | Low | Moderate |

| Recycling | Harder | Easier |

| Applications | Limited | Versatile |

Future Developments and Innovation

On both polypropylenes and polyesters, manufacturing and recycling technology developments will be the shadows of the tomorrow trends. Polypropylene techniques intend to enhance its durability and recyclability, tackling problems in the present. Environmental considerations for polyester developments involve the reduction of emissions during production and the capacity to be recycled into high-grade materials. Both are now poised for greater adoption within sustainable applications as industries shift to green solutions.

Innovations in Polypropylene Fabric Production

The production of polypropylene fabrics is fast becoming one of the most innovative areas catalyzed by insistent demand for greener solutions on the cheap. From the onset, industry insights, and research reported, polypropylene is valued for half of the commercial fabric markets worldwide for its light weight, water-resistant, and durable properties. Using renewable raw materials for green polypropylene developments has been directed toward lessening dependency on fossil energies.

Additionally, according to Global Market Insights latest data, the polypropylene fiber market is estimated to surpass $15 billion by the year 2030, with a CAGR of about 5% during 2022-2030. The packaging area still acts as the driving force using polypropylene for providing greener and flexible packaging alternatives. More technological advancements in the recycling depict how to get high value fiber from post-consumer polypropylene waste, supporting circular economy principles.

In addition, manufacturers are embracing the use of latest technologies such as AI and IoT within production processes to optimize energy consumption and improve the quality of materials. This is to ensure that polypropylene fabrics remain viable alternatives both economically and in respect to sustainability.

Innovative Polypropylene Uses

Due to its versatility and distinctive properties, polypropylene finds uses across various industries. Supported by current market data, the global polypropylene market size was estimated at around USD 124 billion in 2022 and is set to increase at a CAGR of 5.5% until 2030. Rising demands within automotive, packaging, and health-care sectors have induced this growth.

In Automotive: Polypropylene finds wide application in lightweight and durable vehicle manufacture and is also recyclable. Automotive market analysis suggests polypropylene components might bring about a reduction of up to 20% in the overall weight of vehicles, thereby contributing to the enhancement of fuel efficiency and reduction of carbon emissions.

Innovations in Packaging: Packaging industries use polypropylene owing to its water-resistant properties and flexibility. Sales of flexible packaging made out of polypropylene are up by almost 10% with growing applications in food, pharmaceutical, and industrial sectors. Its capacity to increase shelf life while reducing packaging waste is a major reason for this trend.

In Healthcare: There is a rapid increase in the applicability of medical-grade polypropylene in syringes, IV ballast, and medical disposables. Its resistance to chemical sterilization and light yet robust construction makes it a preferred material for the industry. Polypropylene is used by the healthcare sector.

With these advancements in polymer science, bio-based polypropylene has now been developed, which contributes lessly to fossil fuel dependency. Those companies that are utilizing renewable technologies for production report emission reductions of nearly 30% when comparing among conventional polypropylene processes. The creation of this innovative material reflects the theme of solving present situations while still harboring growth in the future.

Research Studies and Development on Polypropylene Fabrics

The field of polypropylene fabrics has experienced some highly advanced improvements as a result of research activities and development endeavors. Closely working to improve the performance, durability, and sustainability of the material, research aims to keep henceforth merchandise in line with mounting needs of the diverse industrial applications. Nanotechnology is one area of research and development aimed at increasing strength, flexibility, heat tolerance, and abrasion resistance. Recent results have demonstrated that polypropylene fabrics enhanced with nanotechnology show a 25% improvement in tensile strength over traditional fabrics, thus making them suitable for use in medical textiles and geotextiles.

Another important research advancement is the production of eco-friendly polypropylene fabrics. With sustainability being at the forefront, scientists are engineering biodegradable polypropylene blends and developing chemical recycling protocols. For example, one catalytical protocol has been engineered to reverse the polymerization of polypropylene waste into monomers, which can then be repolymerized into new plastics, simultaneously reducing waste and the overall carbon footprint of the process by up to 60%. Moreover, bio-based polypropylene derived from renewable sources such as sugarcane and corn accounts for a growing share of polypropylene production, with the global market expected to reach $1.1 billion by 2030, according to industry reports.

Additional innovation in dyeing processes for polypropylene fabric overcomes the difficulties encountered with traditional dyeing methods due to the low dyeability of polypropylene. Plasma treatment and grafting techniques allow a wider color range and reduce water use during dyeing by almost 40%. These technological advances not only open new horizons for aesthetics but also complement worldwide efforts for water conservation.

Further research work on polypropylene fabrics continues to develop and transform the material, ensuring that it remains modern, efficient, and environmentally friendly in an age of fast-paced technological development and sustainability-oriented strategies.

Reference sources

1. Polypropylene/Basalt Fabric Laminates: Flexural Properties and Impact Damage Behavior

- Authors: P. Russo et al.

- Journal: Polymers

- Publication Date: May 1, 2020

- Citation Token: (Russo et al., 2020)

- Summary: This study investigates the mechanical performance of polypropylene/basalt fabric composite samples. The research highlights the significant improvement in mechanical properties when basalt layers are incorporated, particularly in compatibilized samples. The study emphasizes the potential of these composites in eco-sustainable applications, especially in naval and aeronautical fields.

- Methodology: The authors prepared composite samples using film stacking and compression molding procedures. They evaluated the flexural and low-velocity impact behavior of the composites, comparing them with laminates made from pure polypropylene.

2. Development of Unconventional Fabric from Banana (Musa Acuminata) Fibre for Industrial Uses

- Authors: S. Sengupta et al.

- Journal: Journal of Natural Fibers

- Publication Date: August 2, 2020

- Citation Token: (Sengupta et al., 2020, pp. 1212–1224)

- Summary: This research explores the production of needle-punched nonwoven fabrics from banana fiber, aiming to enhance the value of biowaste. The study suggests potential applications in insulation and filtration materials based on the mechanical properties evaluated.

- Methodology: The authors optimized mechanical processing parameters for creating banana, banana-jute, and banana-polypropylene blended nonwoven fabrics. They conducted various tests to evaluate properties such as tenacity, elongation-at-break, and thermal insulation.

3. Characteristic properties of unmodified polypropylene fabrics dyed with pigment dyes in aqueous medium for medical uses

- Authors: S. Gawish et al.

- Journal: Egyptian Journal of Chemistry

- Publication Date: April 2, 2019

- Citation Token: (Gawish et al., 2019)

- Summary: This study examines the dyeing of unmodified polypropylene fabrics with pigment dyes for medical applications. The findings indicate that dyed polypropylene fabrics can be effectively used for medical uniforms and other products, enhancing their antibacterial properties.

- Methodology: The authors employed a direct dyeing method using pigment dyes in an aqueous medium, analyzing color strength, fastness properties, and antibacterial activity against common pathogens.

Frequently Asked Questions (FAQs)

What is polypropylene fabric used for?

Application of polypropylene fabric covers a wide gamut of fields, emphasizing durability and versatility. From packaging, upholstery, to outdoor furniture, one might find polypropylene in just about any product imaginable. Moisture and stain resistance make this fabric suitable for indoor and outdoor applications.

What are the properties of polypropylene?

Being a thermoplastic, polypropylene exhibits many favorable properties. It is strong, light, and resistant to chemicals and UV rays. For this reason, these characteristics make it perfect for putting up woven polypropylene bags and industrial fabric that require durability and longevity.

What are the different types of polypropylene fabric?

There are different kinds of polypropylene fabrics, among which are woven and non-woven types. Woven polypropylene fabric is generally stronger and more durable and hence employed in heavy-duty applications; the non-woven one is mostly used when the fabric is required to be disposable, such as for medical supplies and packaging materials.

How is polypropylene fabric made?

Made out of polypropylene resin extracted from crude oil, the fabric is quite flexible and, through polymerization, can be turned into plastic that can be woven or subjected to a variety of fabric formation processes.

What are the benefits of using polypropylene material?

Polypropylene materials are low cost, durable, and resistant to spills and soils. These properties enable polypropylene fabrics to be versatile and useful in several industries, including food packaging and upholstery, due to their ability to resist wear and tear.

Is polypropylene fabric food packaging safe?

Polypropylene fabric is widely used in food packaging due to its being safe and incapable of leaching dangerous chemicals. This kind of packaging, being resistant to moisture and bacteria, makes the best choice for food packaging.

Is polypropylene fabric used for outdoor furniture?

Yes, polypropylene fabric is used for outdoor furniture, the reason being that it is durable and resists UV rays. Outdoor furniture may tend to get dirty; however, polypropylene fabric will hardly do so and can endure through different weather conditions.

What are the common questions asked about polypropylene?

Common questions about polypropylene include its environmental impact, whether it is safe to use in food, and the difference between woven and non-woven polypropylene. Understanding these factors will empower consumers to make sound decisions regarding the usage of polypropylene products.