High-Density Polyethylene (HDPE) geomembranes are used in a variety of industries for which utmost resilience, flexibility, and environmental protection are necessary. The 40-mil HDPE geomembrane, among many other types, is popular for projects where dependable containment is needed.

This comprehensive guide will illustrate the special characteristics of this material, its applications, and how it benefits industries such as agriculture, construction, and waste management. Whether you’re considering HDPE geomembranes for a project or simply want to learn about this extraordinary product, this article will give you the knowledge to make smart choices.

HDPE Geomembrane – Introduction

HDPE geomembranes are true game-changers in containment solutions for projects. Based on their exceptional durability, chemical resistance, and versatility, they find applications across agriculture, construction, and waste management industries. A 40 mil HDPE geomembrane option will ensure superior performance and eventual success for your project.

Definition and Overview of HDPE Geomembrane

HDPE geomembranes are impermeable liners widely used in environmental, geotechnical, and civil engineering applications. Famous for their long life and resistance to chemicals, these membranes provide reliable containment and barrier solutions.

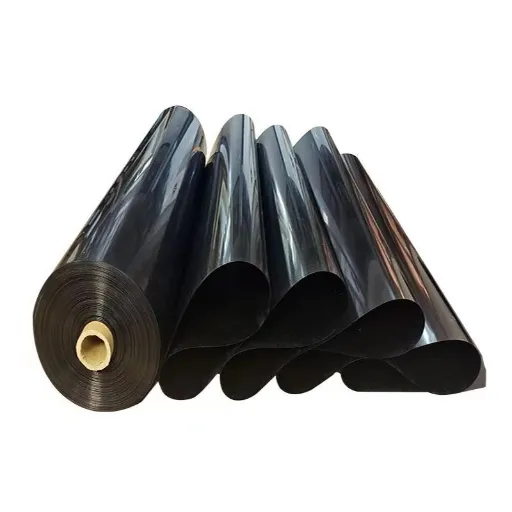

Key Material Properties: HDPE geomembranes are derived from high-density polyethylene resin, creating a robust yet flexible membrane that minimizes leakages and prevents environmental contamination.

This material offers exceptional resistance to:

- UV radiation

- Aggressive chemicals

- Extreme temperature variations

These properties make HDPE geomembranes appropriate for diverse projects, including:

- Landfills

- Wastewater treatment plants

- Mining operations

Standard Specifications

| Property | Specification Range | 40 mil Standard |

|---|---|---|

| Thickness | 30 mil to 100 mil | 40 mil (1.0mm) |

| Tensile Strength | >25 MPa | Optimal for most applications |

| Permeability | <1×10⁻¹³ cm/sec | Excellent barrier properties |

| Service Life | 30+ years | Under proper conditions |

📊 Performance Data: HDPE geomembranes reduce leakage rates by more than 90% in landfill liners due to their superior impermeability.

Forty-mil-thick HDPE geomembranes provide an ideal compromise between flexibility and durability, ensuring long-lasting performance and ease of installation.

Importance of Geomembranes in Modern Applications

Geomembranes have tremendous importance in modern applications due to their durability, impermeability, and cost-effectiveness. These synthetic liners are essential across industries where environmental safety and containment are critical concerns.

Critical Applications Overview

| Industry | Primary Use | Key Benefits |

|---|---|---|

| Waste Management | Landfill liners | Prevents leachate contamination |

| Mining | Tailings storage, heap leach pads | Contains aggressive chemicals |

| Water Conservation | Canal lining, reservoir lining | Up to 50% water savings |

| Agriculture | Irrigation systems | Reduces water loss in arid regions |

Environmental Protection: Recent studies demonstrate that geomembranes in landfill liners prevent harmful leachates from seeping through soil into groundwater, protecting ecosystems and public health.

Applications and Benefits of Geomembrana HDPE

Geomembrana HDPE is indispensable across numerous applications. From landfill lining to water containment, mining operations, and agricultural water storage, HDPE geomembranes are the preferred choice for preventing leaks while withstanding chemical attacks and maintaining impermeability.

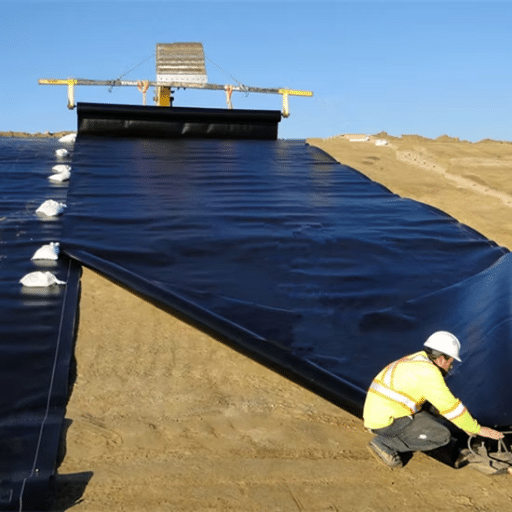

Uses in Landfill and Waste Management

Due to its superior chemical resistance, impermeability, and durability, Geomembrana HDPE plays a vital role in landfill and waste management systems, preventing soil and groundwater contamination from hazardous leachate.

1. Base Liners

- Widely employed in landfill base liner construction

- Prevents leachate seepage into soil and water table

- Permeability as low as 1×10⁻¹³ cm/s

- Serves as an effective barrier against pollutants

2. Final Capping Systems

- Seals waste at end of landfill operational life

- Reduces odor emissions

- Inhibits rainwater infiltration

- Prevents additional leachate generation

3. Gas Collection Systems

- Collects and vents landfill gases (methane)

- Generated by decomposition of organic waste

- Well-engineered systems collect nearly 80% of generated methane

- Captured methane can be converted to energy

4. Leachate Collection Systems

- Channels leachate to collection facilities

- Prevents uncontrolled emission

- Advanced designs reduce contamination risk by up to 90%

- Works in conjunction with geotextiles

Role in Aquaculture and Fish Ponds

HDPE geomembranes play a crucial role in modern aquaculture and fish farming by providing efficient and sustainable water management systems. These geomembranes act as liners to form impermeable barriers that maintain required water levels without contamination from soil infiltration or leakage.

Primary Benefits in Aquaculture:

| Benefit | Description | Impact |

|---|---|---|

| Durability | Resistant to UV, chemical degradation, biodegradation | Long-term outdoor use |

| Tensile Strength | Withstands environmental stressors | Handles water level fluctuations |

| Smooth Surface | Prevents bacteria and algae growth | Reduces disease outbreaks |

| Biosecurity | Prevents soil-water interaction | Protects from contaminants |

📈 Market Growth: The global fish-farming market is projected to reach $376 billion by 2025 at a CAGR of 5.8%, with HDPE geomembranes contributing to cost-efficient and resource-efficient production.

Comparative Analysis with Other Materials

Geomembranes possess superior ability to withstand mechanical forces, handle flexural deformations, and resist chemicals compared to other liner types. Their sealing capability against leakage significantly exceeds traditional liners such as clay or concrete, while offering better longevity and cost-effectiveness.

HDPE vs. PVC: An In-depth Comparison

High-Density Polyethylene (HDPE) and Polyvinyl Chloride (PVC) are the most common geomembrane materials. Each material fits specific project requirements based on unique characteristics.

| Comparison Factor | HDPE | PVC |

|---|---|---|

| Durability & Strength | • High environmental stress resistance • Excellent UV degradation resistance • 15-20 year lifespan with proper maintenance |

• Less UV resistance • Requires UV stabilization • Good performance in protected environments |

| Flexibility | • More rigid material • Less flexible for complex surfaces • Provides higher stability when installed |

• Superior flexibility • Easier installation on uneven surfaces • Better for non-standard applications |

| Cost Considerations | • Higher initial investment • Lower long-term maintenance costs • Better durability value |

• Lower initial cost • Cheaper installation • Higher maintenance over time |

| Environmental Impact | • 100% recyclable • Minimal chemical leachate • Environmentally friendly |

• Contains plasticizers • Chemical additives may leach • Potential risk to sensitive ecosystems |

| Aquaculture Performance | • Maintains structural integrity long-term • Resistant to punctures and tears • Recommended for permanent installations |

• Suitable for small-scale projects • Flexibility advantage in handling • Good for temporary applications |

Exploring the Environmental Impact of HDPE Geomembranes

From environmental impact perspectives, HDPE geomembranes represent a more sustainable solution given their longevity, chemical resistance, and recyclability. They rarely require replacement, enabling tremendous sustainability benefits, while their chemically inert nature prevents harmful leachates from affecting the environment.

Recyclability and Sustainability of HDPE

Sustainability Highlights: High-Density Polyethylene is considered one of the most recyclable and environmentally sustainable materials used in technical applications.

Key Sustainability Features:

- Recycling Rate: Approximately 30% recycling rate globally (higher than PVC)

- Material Retention: Recycled HDPE retains original strength and performance properties

- Secondary Applications: Used in pipes, construction materials, and new geomembranes

- Carbon Footprint: Lower CO₂ emissions during manufacturing compared to alternatives

- Energy Efficiency: Advanced production technology reduces energy consumption

🌱 Life Cycle Benefits: Life cycle analysis shows HDPE geomembranes can be recycled and re-entered into the supply chain, reducing landfill disposal while lasting for decades.

Impacts on Soil and Water Quality

HDPE geomembranes excel in protecting soil and water quality as impervious liners, preventing leachates and pollution from heavy metals, hazardous chemicals, and toxic substances.

Water Quality Protection:

| Application | Protection Method | Effectiveness |

|---|---|---|

| Landfill Sites | Impervious barrier | Marked decline in water body contamination |

| Agricultural Areas | Nutrient runoff control | 90% reduction in water contamination risk |

| Industrial Sites | Chemical containment | Impermeability below 1×10⁻¹² cm/s |

Soil Quality Benefits:

- Prevents infiltration of nitrogen and phosphorus

- Maintains soil fertility in adjacent areas

- Controls agricultural runoff pollution

- Ensures minimal water seepage in irrigation systems

Reference sources

- Market.us – Geomembrane Market Report

This source provides an in-depth analysis of the geomembrane market, including the dominance of HDPE geomembranes, their applications in waste management, mining, and water conservation, and their market growth trends.

Source Link - Grand View Research – HDPE and LLDPE Geomembrane Market Report

This report offers insights into the market size, applications, and regional trends of HDPE geomembranes. It highlights their use in mining, water management, and construction, along with regulatory impacts and technological advancements.

Source Link - Bioplas Mx – Geomembrana HDPE

This source discusses the practical applications of HDPE geomembranes in aquaculture, irrigation ponds, and landfills, emphasizing their environmental benefits and durability.

Source Link

Frequently Asked Questions (FAQs)

The geomembrana HDPE, or high-density polyethylene geomembrane, refers to an impermeable membrane used for containment applications. It prevents seepage and controls water resources, finding wide applications in landfills, aquaculture, and industrial areas due to its high mechanical strength and environmental stress cracking resistance.

Specifications include thickness ranging from 1mm to 2mm, with 40 mils being a common choice. It features excellent tensile strength, UV and chemical resistance. The geomembrane is manufactured in both smooth and textured surfaces, with textured options chosen to maximize performance for specific applications.

Selection depends on project requirements, environmental conditions, and containment type. Consider thickness (mils), texture (smooth or textured), and chemical resistance. Consult with qualified geomembrane suppliers or manufacturers for guidance on the best option for specific requirements.

Advantages include high durability, waterproof characteristics, UV radiation resistance, and chemical resistance. This makes it suitable for landfill liners, fish ponds, and irrigation systems. The impermeable nature ensures containment while minimizing environmental pollution.

Several types are available, including high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and PVC geomembranes. Each offers different properties such as flexibility, chemical resistance, and thickness options for specific application needs.

The lifespan varies depending on environmental conditions, UV exposure, and mechanical forces. Generally, properly installed and maintained HDPE geomembrane systems easily exceed 30 years. Their environmental stress crack resistance and high durability ensure long service life.

This comprehensive guide provides essential information for making informed decisions about HDPE geomembranes. For specific project requirements, consult with qualified professionals to ensure optimal material selection and installation.