Geogrid Mechanically Stabilized Earth (MSE) walls are among the most effective and long-lasting retaining wall solutions. These structures are perfect examples of modern construction in their elements of durability, cost-effectiveness, and flexibility of design. They can thus be applied to a broad spectrum of projects, from infrastructure to commercial real estate. This blog post will focus on the main advantages of geogrid MSE retaining walls, their operating principles, and reasons for becoming a sought-after solution in civil and landscape engineering. Moreover, the contractor, engineer, or landowner will benefit from the valuable insights into innovative walls that can make their next project a success.

MSE Walls and Geogrids: A Thorough Overview

MSE walls and geogrids prove to be strong, affordable, and creative ways of dealing with retaining wall issues. The walls, composed of soil reinforcement and geogrid materials, give a huge woof, life, and plant-like behavior, thus, get various engineering and gardening projects done with ease.

Understanding MSE Walls

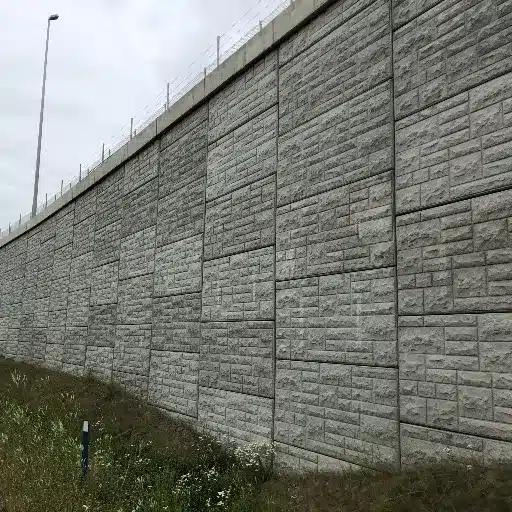

MSE walls are high-tech retaining wall formed by mixing together reinforced earth and compacted granular soil giving them enhanced strengths and stabilizing toughness. These walls are dispensed for soil retention, mostly in a steep terrain and thus, turned out to be good for roads, bridges, railways, and other infrastructural projects. Occasionally, the reinforcement materials utilized in MSE walls consist of geosynthetics like geogrids, which are easy to handle, strong, and have a good load-bearing ability.

Key Insight: New MSE walls are recognized not only for being cheaper but also for their less time-consuming but more versatile nature than other constructions in various locations. Research shows that MSE walls can cut down the construction time by 50% at most when put alongside conventional retaining walls; besides, the flexibility in design grants them better performance in case of earthquakes. Their infinite modularity makes easy repairs and adjustments possible, thus, being a long-term sustainable solution for the most complicated engineering problems.

Contribution of Geogrids to Reinforcement

Geogrid is an essential ingredient in the making of MSE (Mechanically Stabilized Earth) wall and so it brings in strength, stability, and longevity. Made by the manufacturers for a purpose, these materials are to even-out the load and improve the mechanical properties of the soil. Geogrids are made from synthetic materials and have a closed grid structure which enable interaction between soil and the reinforcement.

Performance Data: The technological developments with respect to geogrids have been quite impressive and their performance has improved in the process. For example, the research supports the point that geogrids can lead to an increase of the bearing capacity of soils up to 200%. So, rather than getting rid of the weak or loose soils, geogrids can work in a manner by making the soil strong enough to handle the load. Furthermore, geogrids enhance the tensile strength of MSE walls, hence, the walls would be able to bear heavy loads and resist forces coming from earthquakes.

Benefits of Using Geogrids in Retaining Wall Systems

Geogrids were very beneficial to retaining walls because the walls got better in the whole area of stability and strength. They helped in displacing stresses, improving soil reinforcement, and increasing bearing capacity. Also, they served as a load and seismic force resistance support that made the wall system and, therefore, the infrastructure project overall a reliable and effective solution in various cases.

Enhanced Structural Integrity

A very important fact is that geogrids not only helped the world to be a little refuges of giant and powerful forces but to be “super giants” in that aspect that they were given the role of pointing out the Earth’s core’s pressure and dispersing the bearing of the walls through these giant earthen activities inside. Studies have found that with the use of geogrid-reinforced retaining walls, the load capacities of up to 50% higher compared to the conventional methods can be practiced, thus being significantly improved in a wide assembly of their applications – highways, urban development, industrial sites, etc.

Material Technology: In fact, these improvements that brought new horizon in geotechnical engineering and construction have been traced to geosynthetic technology application areas. For instance, modern geogrids are made of high-density polyethylene (HDPE) or polypropylene materials, providing not only great tensile strength but also resistance to the environment in terms of UV degradation, moisture, and chemicals. Industry studies show that the application of geogrids may lead to a prolongation of the retaining wall’s system’s lifespan by 25 to 40 years.

Cost-Effectiveness and Durability

The use of geogrids in constructions not only ensure the combined effect of cost-saving and durability but also strong dependence on the long run. The main reason for that is they produce a less than necessary quantity of conventional materials like concrete and aggregate by reinforcing soils, which directly reduces the construction costs and thus paying off the expenses of the new materials. Researches have revealed that up to a 30% reduction in cost due to material savings and quicker installation times is possible when geogrids are used in the road construction. They are also a factor prolonging the life cycle of infrastructure. In the case of pavement systems, for instance, geogrids cause less rutting and cracking which goes hand in hand with the increase of the structure’s durability through the extension of the service life by 50% or more.

Long-Term Value: What’s more, geogrids are a major contributor to lower maintenance costs. Roads and walls which are geogrid stabilized need and hence are less demanding repair-wise leading to an overall saving in the long run. A recent report has given the figures to backup that claim stating that the costs of maintenance interventions for highways having geogrid support were 35% lower over a time of 20 years in comparison to traditional one. This combination of immediate cost savings during the construction and reduced long-term expenditures is pointing out the significance of geogrid technology in producing sustainable, durable, and cost-effective infrastructure projects.

Recent Innovations in Geogrid Technology

Recent advancements in the field of geogrid technology have been mainly geared towards the creation of stronger materials, more flexible ones, and sustainable production processes. Among the innovations, to cite just a few, I can mention the high-performance polymer coatings that durably, and environmental-wise, the process and materials are the biodegradable ones that unconditionally support eco-friendly practices.

Advancements in Geosynthetic Materials

The new and sustainable materials in the geosynthetic sector have gained lots of experience and hence developed their performance in modern engineering applications. The major breakthrough has been the production of high-strength polymer blends that offer not only durability but also resistance to factors affecting environments like UV radiation, chemicals, and very high to very low temperatures. Thus, this area can provide infrastructure solutions that last even under such difficult situations.

Nanotechnology Breakthrough: The turning of geotechnical materials implication in the evolution of nanotechnology is the most recent and practical of all the various changes that have come about in the manufacturing of geosynthetics. The case in point is geogrids which are now having one of the best load distribution capabilities, thus enabling stabilization of soil and slopes in a very strong way. Research in 2022 showed that the use of new nanocomposites in the production of geosynthetics has increased their load-bearing capacity up to 40%, thus avoiding the risk of soil erosion and structural failure.

Introduction of Uniaxial and Biaxial Geogrids

| Geogrid Type | Characteristics | Applications |

|---|---|---|

| Uniaxial Geogrids | Strengthening in one direction is mainly geogrids’ main application; they are best for slope stabilization and other infrastructure projects like reinforced retaining walls where the tensile stress is directed along one axis. For instance in a reinforced soil wall, the application of uniaxial geogrids increases the load that can be safely applied to the wall, hence leading to less deformation and providing stability for a long period. |

|

| Biaxial Geogrids | Biaxial geogrids are unlike the uniaxial geogrids that offer different strength properties along the two axes, they possess the same strength in both directions. This makes them the best choice for different engineering applications, such as subgrade stabilization, road construction, and airport runways, where tons of stress are applied in those directions and hence the need for good distribution. Research on the performance of biaxial geogrids in road projects showed that their technical lifespan can be increased by over 50%, thus resulting in a big cut in the maintenance budget. |

|

Application Summary: I would summarize that biaxial geogrids are indispensable for projects that need multi-directional strength, such as road building and airport runways. Their property of stress distribution in an even manner along the surface adds significantly to their durability and also lowers the maintenance cost, thus, they are regarded as a cost-effective solution in such scenarios.

Practical Applications and Case Studies

Successful MSE Retaining Wall Projects

1. Reinforcing Highways in California, USA

An extraordinary example of MSE walls’ application was in the widening of California’s Interstate 5 close to San Diego. The project came with the challenge of building of retaining walls to support the highway on uneven and hilly areas. Engineers made use of geogrid-reinforced MSE walls, so they were able to install them quicker and save over 20% of the budget even when compared to the case of conventional concrete walls. The walls rose as high as 40 feet and managed seismically without flouting the rigid regulatory requirements.

2. Protecting Coastal Railways in the UK

The Dawlish coastline in Devon where the MSE walls were constructed was the site of a critical but badly eroded railway link for the UK due to the constant pounding of the waves. In order to protect the railway line, the engineers came up with MSE retaining walls that were reinforced with steel and polymer-coated geogrids, giving the walls a lifespan in salt water that was even longer than the beaches around them. Project statistics reveal that the use of MSE reduces the time required for construction by 30% when compared to the old-fashioned way of doing it.

3. Supporting Residential Developments in Dubai, UAE

MSE walls have become common in Dubai for both residential and commercial projects. As an example, the Al Furjan residential area needed to be designed for maximum use of the land and slope stabilization. The community design won the MSE retaining walls incorporating locally sourced fill materials and geogrids that were installed to provide stability while blending aesthetically into the community design. The project minimized material transport costs and was, therefore, able to cut total costs by 15% while still allowing quick construction phases.

Overcoming Challenges in Real-World Situations

MSE (Mechanically Stabilized Earth) retaining walls have encountered and successfully dealt with various challenges in practical applications. One significant problem is the seismic regions where the stability of the ground and safety are the major issues. The use of advanced geogrid technologies as well as innovative batch designs has playing the major role in reducing the risks of earthquakes. For instance, studies demonstrate that well-reinforced MSE walls can handle seismic occurrences with up to 0.9g peak ground acceleration, thereby causing little deformation and not losing their structural integrity.

Water Management Solution: The other challenge that is quite common is the situation in high-water-table areas or districts subjected to heavy rainfall. The effects of such conditions may be the build-up of hydrostatic pressure and the possibility of erosion. MSE walls are now equipped with the most advanced drainage systems that are able to efficiently divert water flow, thereby lowering the water table and increasing the life of the wall. It has been found that drainage systems that are optimized for performance can lead to a 30% increase in wall performance during extreme weather conditions.

Expert Tips for Selecting and Applying Geogrids

Best Practices in Installation and Reinforcement

Site Preparation and Assessment

Start with a detailed site preparation where geogrids will be laid down. Make sure that the foundation soil is well compacted and not contaminated with dirt, rocks, or anything else that could cause unevenness and the geogrid would not be able to perform properly. Perform a soil test to judge its compatibility with the chosen geogrid type since bad foundation conditions might lead to structural problems in the long run.

Accurate Geogrid Placement

Geogrids should be placed very accurately in order to get the best reinforcement. The manufacturer’s recommendations for spacing, overlap, and anchoring should be closely followed. For example, layers laid on top of each other generally need to have a minimum overlap of 12 inches (30 cm) in order to avoid being separated due to load stresses.

Tensioning During Installation

Tensioning of the geogrid done properly is very important for maintaining alignment and the integrity of the structure. Tension should be applied slowly so that the material gets flattened and load stresses are distributed uniformly over its surface.

Considerations for Wall Height and Backfill Material

Wall Height

The retaining wall height is one factor that has an impact on the geogrid layers’ required strength and spacing. If the height of the wall is more than 10 feet then the industry standard recommends installation of geogrids at intervals of 2 to 3 feet vertically in order to have stability. In case of taller walls, geogrids with more tensile strength are generally needed and specially at the base geogrids will have to be stronger to counter the increased earth pressure. A study has found that in extremely high walls (15 feet and above), the application of sophisticated geogrid systems can bring down the lateral wall displacement by 35% max.

Backfill Material

The option of backfill material is one more fundamental factor to take into consideration as it has a say in the drainage, compaction and load distribution. Coarse soil like gravel and sand are usually the ones chosen because of their good drainage and their feature of being easy to compact. A study has shown that wall stability can be improved by up to 20% with the use of well-graded granular backfill as compared to the use of clay soils and fine-grained soils. Furthermore, with very good drainage provided by high-quality backfill materials, the development of hydrostatic pressure that might damage the wall is prevented. It has also been claimed through research that the application of geotextile drainage systems along with properly selected backfill can result in a 30% increase in the life of retaining walls.

Reference Sources

-

Geoquest USA

This source discusses the versatility, durability, and load-bearing capacities of MSE walls, making it a go-to resource for civil engineers and construction teams.

Geoquest USA – Mechanically Stabilized Earth (MSE) -

Federal Highway Administration (FHWA)

The FHWA provides detailed guidelines and high-quality information on the use of MSE walls in public infrastructure projects, ensuring their reliability and compliance with industry standards.

FHWA – Mechanically Stabilized Earth (MSE) Wall Fills -

Market Report Analytics

This report highlights the strategic adoption of MSE walls in transportation projects, land reclamation, and other infrastructure initiatives, showcasing their growing importance and feasibility.

Market Report Analytics – Mechanically Stabilized Earth Retaining Wall

Frequently Asked Questions (FAQs)

What Are the Benefits Of Employing Uniaxial Geogrid In MSE Walls?

The use of the uniaxial geogrid in MSE walls has a number of benefits, such as better soil reinforcement and improved wall performance. The uniaxial configuration permits the efficient transfer of load along with the stabilization of reinforced soil slopes, which is very important for the integrity of taller walls.

What Are The Design Criteria For Mechanically Stabilized Earth Walls?

Design criteria for mechanically stabilized earth walls comprise the type of soil, the height of the wall, the loading conditions, and the specifications of the geogrids as the main factors to be considered. The design engineer is thus responsible for making these assessments to be sure that the wall system is capable of bearing the project-specific demands and the requirements for long-term performance.

How Does Corrosion Impact MSE Wall Installation?

Corrosion can have a huge negative impact on MSE wall installation and performance, especially when the wall uses metal components like wire mesh. The use of corrosion-resistant materials and careful selection of construction techniques according to environmental conditions are some ways to minimize corrosion risk during wall construction.

What Are The Functions Of Precast Concrete Panels In Retaining Wall Systems?

Precast concrete panels are widely utilized in retaining wall systems because of their structural integrity and easy installation. It is possible to combine the panels with geogrid reinforcement to form a strong and long-lasting MSE wall that controls the soil behind the wall effectively.

Is It Possible To Build MSE Retaining Walls In Steep Slopes?

MSE retaining walls are particularly amenable to use on steep slopes. By the pairing of geogrid reinforcement and good design practices, it is possible for these walls to bear large loads and be stable even in difficult areas.

Final Thoughts

Geogrid MSE retaining walls represent a sophisticated, cost-effective, and sustainable solution for modern infrastructure challenges. By understanding their benefits, innovations, and best practices in installation, you can ensure the success of your next construction project.