When speaking about water drainage and erosion control in the aspect of landscaping, the choice of materials is of utmost importance. Geotextile fabric has become a world changer in the landscape drainage solutions market, especially for French drains. It has provided an alternative for engineers to improve drainage efficiency while preventing clogging and soil instability. This blog will explain what geotextile fabric is, how it works, and why it is essential for an effective and durable French drain. Be it a landscape professional or a do-it-yourselfer; this guide will value your insight when making your next drainage project.

Introduction to Geotextile Fabrics

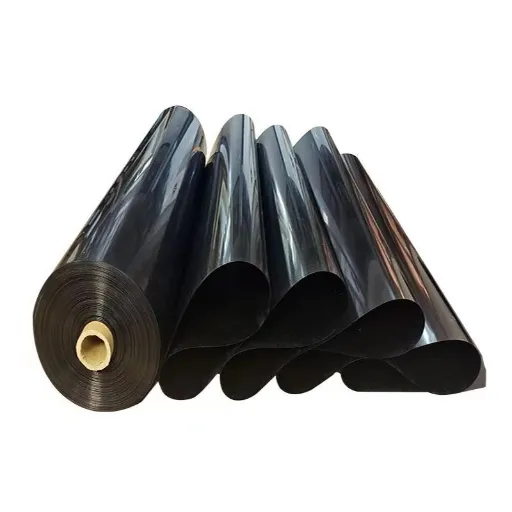

Geotextile fabric is a permeable substrate of synthetic fibers that aid drainage and filtration. In other words, a geotextile fabric keeps soil and debris from clogging a drainage system while allowing water to flow. Therefore, a geotextile fabric is an invaluable material in constructing an efficient and long-lasting French drain.

Definition and Purpose of Geotextile Fabrics

Geotextile fabrics are man-made textile materials manufactured from synthetic fibers like polypropylene or polyester. Their function is to let water pass through while keeping soil particles and debris out. They are primarily concerned with enhancing the stability, filtration, separation, and reinforcement of soil systems in various construction and landscaping applications.

Market Insight: According to the latest data, due to the rising applications in civil engineering, the global geotextile fabric market is projected to hit the $10.7 billion mark by 2027 and support its efficiency in making infrastructure more durable. Also, geotextile fabrics are put to use in such projects as French drains, road construction, erosion control, and retaining walls. In case of French drains, geotextile fabrics provide a barrier against soil intrusion so that the drain system lasts for a longer time and requires minimal maintenance. Modern drainage has come to rely on geotextile fabrics because they combine strength, permeability, and adaptability.

Types of Geotextile Fabrics

| Type | Construction Method | Primary Applications | Key Characteristics |

|---|---|---|---|

| Woven Geotextiles | Interlacing polypropylene or polyester fibers | Road construction, retaining walls | High tensile strength (up to 200 kN/m), excellent for heavy loads |

| Non-Woven Geotextiles | Needle-punched or heat-bonded | French drains, landfill liners, erosion control | High porosity, permeability rate of 0.1 to 0.5 cm/sec |

| Knitted Geotextiles | Interlooping yarns | Specialized applications, irregular surfaces | Balance of strength and flexibility, better adaptability |

Woven Geotextile Fabrics

Woven geotextiles are formed by interlacing polypropylene or polyester fibers in a crisscross manner, providing great tensile strength. These fabrics are mainly used where stabilization and reinforcement are needed, such as road construction and retaining walls. Because of their high load-bearing capacity, woven geotextiles are especially useful for heavy loads and high-pressure situations. It has been reported that woven fabrics are able to take up to 200 kN/m tension strength and are, therefore, excellent for heavy-duty jobs.

Non-Woven Geotextile Fabrics

Non-woven geotextiles can be needle-punched or heat-bonded in the making, resulting in felted, porous materials. These fabrics are perfect for filtration, drainage, and separation, as they offer high porosity to permit water through while not letting soil pass. They get predominantly used in French drains, landfill liners, and erosion control systems. Non-woven geotextiles will provide a permeability rate of about 0.1 to 0.5 cm/sec, depending upon the thickness and density of the material.

Knitted Geotextile Fabrics

Knitted geotextiles are made by interlooping yarns and provide a compromise between strength and flexibility. Even though they are comparatively less common, they are highly specialized and therefore of interest to unique applications that require strong but adaptable materials. Knitted fabrics have a much better flexibility to irregular surfaces and areas with complex geometries.

Importance of Drainage in Construction and Landscaping

Drainage is vital in construction and landscaping to prevent the accumulation of water that may eventually bring serious harm to structural integrity, soil erosion, and reduction of stability. Water drainage leads to the structures’ permanence and safety, while they help in promoting the viability of plants by avoiding water downstream.

Challenges Without Proper Drainage

Drainage is among the criteria of construction and landscaping that could give rise to various severe challenges if not appreciated well: Obviously, water accumulation can damage the foundation, leading to instability and eventually to failures of structures. Beyond those, also, improperly channeled runoff can erode soils, thereby decreasing land stability and deterring aesthetic development. Additional water accumulation may lead to flooding and cause the area to be useless and eventually to incur great expenses for repair.

Critical Statistics: Another adverse effect on roadways is the lack of adequate drained systems. Water standing on paved surfaces contributes 30-40% to the formation of potholes and surface disintegration. Extended exposure to moisture can likewise encourage mold and mildew growth, and such a situation might turn out to be a health hazard within residential homes and commercial setups. Urban flooding in the U. S. counts improper drainage among its leading causes, and this alone causes billions of dollars in damages in a single year, according to the U. S. Environmental Protection Agency (EPA) data.

Geotextiles in Drainage Enhancement

Modern drainage systems use geotextiles to augment water flow and prevent soil erosion, thus stabilizing soil. Such permeable fabrics are manufactured for separation, filtration, reinforcement, and drainage purposes in varied construction and landscaping projects. Geotextiles allow water through but retain soil particles, thus preventing drainage collapse, which is of paramount importance in regions prone to excessive rainfall or floods.

Industry Growth: As per the report, the global market for geotextiles, at a CAGR of 9.2% between 2021 and 2028, is driven by the rise in demand for sustainable infrastructure. For one, it is noted that geotextiles could prolong infrastructure life by up to 30% by efficiently managing groundwater and on-site surface runoff. Being cost-effective, they are preferred options for fastening projects like highway construction and small operations such as residential landscaping.

French Drain Applications

Residential Applications

Basement Waterproofing

French drains become a major line of defense to keep basements dry. Diverting water away from the edifice, it thereby prevents structural damage and the growth of mold. Recent figures suggest that almost 85% of leaks in the basements take place due to inadequate drainage, something which can be taken care of by supplying a French drain system.

Landscaping

French drains control the flow of water for gardens, lawns, and yards, removing waterlogging and keeping soil conditions favorable. Drainage helps maintain the aesthetic appeal of an area while preventing root rot of plants altogether caused by excess moisture.

Commercial and Industrial Applications

Infrastructure Protection

French drains usually serve the purpose of preventing water accumulation along roads, bridges, and parking lots. Studies reveal that with a proper installation, French drainage systems can achieve up to 60% reduction in water pooling incidents in urban areas.

Agricultural Fields

In cases, where the efficient management of water becomes imperative for crop production, French drains fix the soil and erosion into optimally moist conditions, hence providing a long-term basis for farming.

Advantages of Using Geotextile Fabric

Several important benefits are given by the use of geotextile fabrics. In my opinion, they will improve drainage efficiency, minimize erosion, and help the French drain systems last longer as they prevent debris and sediment from entering into the drainage channel. This is why they are critical components for urban infrastructure as well as agricultural applications.

Durability and Sustainability

Geotextile fabric plays a very important role when it comes to the durability and the sustainability of drainage systems, such as French drains. The fabric acts as a very sturdy preventive barrier between the soil and any unwanted clogging debris, thus minimizing clogging. Studies have shown that these fabrics may enhance the drainage systems’ life by as much as 50%, thereby greatly reducing future maintenance costs for landowners. These fabrics can endure harsh and adverse environmental conditions such as temperature changes and huge water pressure for long-term performance scenarios under various conditions.

Sustainability Impact: From a sustainability perspective, many of today’s geotextile fabrics are produced with eco-friendly materials. Recycled polymers and biodegradable options gain popularity as a large-scale effort to minimize impact on Earth’s environment. As well, they germinate water conservation by providing for drainage with lesser water logging situations in agriculture and urban areas. Environmental literature bring a research base where geotextiles in modern constructions can optimize at 30 to 40 percent saving in water waste compared to old drainage systems and thus they prove to be a futuristic solution towards sustainable development.

Cost-Effective Nature

Geotextiles are environmentally impacting and yet cost-effective in many applications. Their durability and longevity decrease periodic or frequent maintenance costs, thus presenting considerable savings over time. For instance, estimates recently put down the use of geotextiles in road construction as a means to reduce the entire cost of the project by about 25%-30%, as it lessens the quantity of raw material required and enhances the durability of the roads. Furthermore, in erosion control or drainage systems, compared to conventional methods, undertaking geotextiles would help lower the labor and material costs by roughly 20%.

| Cost Benefit | Savings Percentage | Application Area |

|---|---|---|

| Project Cost Reduction | 25-30% | Road construction |

| Labor and Material Costs | ~20% | Erosion control and drainage systems |

| Project Timeline Reduction | ~15% | Various construction projects |

| System Lifespan Enhancement | Up to 50% | Drainage systems |

Geotextiles are also touted for their own environmental efficiency. For example, by stabilizing soils in construction, they avoid the erosion of soil and thus assist in averting costly remedial measures. Research has shown a potential shrinkage of project timelines by a margin of some 15% with the use of geotextiles, thereby boasting decrease in labor costs and the finishing of works sooner. Thus, these attributes make geotextiles fiscally viable, with saving costs aligning with sustainable efforts in all various industrial fields.

Recent Innovations and Trends

Latest Materials or Technologies in Geotextiles

Recent advances in geotextile materials and technologies have been key factors in widening the possible scope of applications and increasing the level of performance of geotextiles across different sectors. The biggest recently known innovation includes that of nanotechnology in geotextile manufacture. Nanomaterials such as graphene and carbon nanotubes have helped manufacturers to increase tensile strength, enhance flexibility, as well as offer greater resistance to weathering caused by UV radiation and chemical exposure.

Biodegradable Innovation: The biodegradable geotextiles are, in fact, becoming increasingly popular as a truly sustainable alternative to the traditional synthetic options. Materials like jute and coir are now being developed with special treatments to extend durability while retaining eco-friendliness. By way of example: according to studies, jute geotextiles can reduce soil erosion by up to 68% on agricultural lands and are fully biodegradable within a period of two years, leaving behind no environmental footprint.

Innovations in Permeable Landscape Fabrics

Being slightly permeable, a subset of landscape fabrics permits the penetration of water and air and controls sustainable landscaping and erosion with respect to techniques. Most of these fabrics are composed of polypropene (polypropylene) or polyester and are produced with the utmost careful advanced weaving or non-woven technology so as to meet the desired levels of permeability. They are extensively used for weed control by encouraging water flow and soil aeration.

Market Forecast: In recent years, permeable landscape fabrics with biodegradable offerings have also come into the market, like those of jute or coconut coir. These environmentally conscious options are preferred for temporary erosion control applications, with their capacity to decompose slowly and contribute to soil enrichment. According to market research, this demand for green solutions is actually burgeoning at a CAGR of 7.8%, and the global landscape fabric market is anticipated to hit $4.37 billion by 2028.

Reference Sources

-

Fabric Pros Blog

- Title: Drainage Fabric: Everything you Need to Know

- URL: Fabric Pros Blog

- Why Reliable: This blog provides detailed insights into the applications and benefits of drainage fabrics, specifically for landscaping and water management.

-

Polyfabrics Blog

- Title: Which Geotextiles are Ideal for Drainage?

- URL: Polyfabrics Blog

- Why Reliable: This source discusses the types of geotextiles suitable for drainage and their applications in civil and landscaping projects.

-

Quora Discussion

- Title: What are the Key Uses and Advantages of Geotextile Fabric?

- URL: Quora

- Why Reliable: This platform features expert opinions and practical examples of geotextile fabric usage in infrastructure and drainage systems.

Frequently Asked Questions (FAQs)

How does non-woven differ from woven-geotextile?

The primary difference between non-woven and woven geotextile fabrics lies in the construction. Non-woven fabrics are formed through the entanglement of fibers, providing good drainage and soil separation characteristics, while woven fabrics are made by interlacing threads, which might grant them a higher load capacity but less flexibility for drainage uses.

What are the main uses of geotextile landscape fabric?

Geotextile landscape fabric can be used for several things, including weed control, retaining soil, and providing a firm standing area for various uses. It separates different soil layers to allow drainage and prevents the mixing of materials, thereby ensuring the durability of landscaping projects.

What is the function of the geotextile filter fabric in the drainage system?

Geotextile filter fabrics are used in drainage systems to keep sediments from clogging pipes and drainage structures. It permits the passage of water and retains clay-like particles, thereby aiding in drawing water out and keeping out sediments that might clog drainage pipes.

What are the usual weights of nonwoven geotextile fabric?

Nonwoven geotextile fabric is offered in a range of weights such as 4 oz, 8 oz, etc., depending on the application. Typically, heavier weights like 8 oz might be specified for dimmer heavy-duty or abuse areas, whereas a lighter 4 oz fabric might work in lighter applications.

Can geotextile drainage fabric be used for driveway installation?

Geotextile drainage fabric can effectively be used for driveway installation. The fabric provides a suitable traversing good base and drainage for the subgrade down below. Without this drainage, the subgrade could begin to retain water and swell, settling and cracking the driveway surface above.

What is the load capacity of heavy-duty geotextiles?

Heavy-duty geotextiles are made to take considerable loads and are used in all areas of road building and driveways. Depending on the specific fabric and weight, the load capacity may vary, with alternatives being made to fit the needs of any project.