The decision regarding the materials is of great importance in construction of roads that are not only durable but also environmentally friendly. A very important yet sometimes neglected material in contemporary road building is the geotextile fabric. These technical fabrics, which come in different types of weave, are designed to boost the road performance, increase the stability of the road, and give the infrastructure a longer life. But the challenge comes when the project has so many options available that one finds it difficult to comprehend which type of weave would suit best. This guide is going to introduce you to different types of geotextile fabric weaves, their uses, and their contributions to the success of road construction projects. If you are a contractor or just curious about the use of new materials in infrastructure, this article will give you the information you need to make sound choices.

Geotextile Fabric Introduction

I would select the geotextile fabric texture for my project that is most suitable for the specific application requirements. In case strength and stability are the main factors, I could go for a woven geotextile. However, if the main factors are drainage and filtration, then non-woven geotextile would probably be the more suitable choice.

Geotextile Fabric Definition

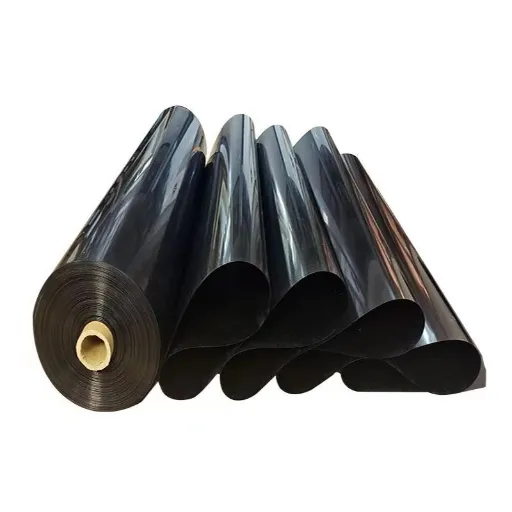

Geotextile fabric is a synthetic, permeable material composed of either polypropylene or polyester, with the purpose of improving soil stability, drainage or acting as a protective layer in different civil engineering and construction applications. These fabrics are widely used in road constructions, retaining wall support, erosion control, and drainage works because of their superior strength and durability.

Depending on the manufacturing process, there are two types of geotextile fabrics—the woven and the non-woven. Woven geotextiles are produced by interlacing at right angles two or more sets of yarns, thereby giving them high tensile strength which makes them very suitable for load-bearing applications like roads or highways. In contrast, non-woven geotextiles are produced by bonding through heat, chemicals, or needle punching, and are thus more suitable for filtration and drainage tasks owing to their uniform pore sizes.

The Use of Geotextiles in Road Construction

Geotextiles are the backbone of modern road construction as they enhance, in addition to the longevity, durability and cost-effectiveness, the overall performance of the road. Fabrics are primarily utilized for their features of separation, reinforcement, filtration, and drainage. Recent research indicates that proper usage of geotextiles may protract the life of pavement by 50% as intermixing of subgrade and aggregate layers will be prevented. Apart from road strength under heavy traffic and harsh weather, this separation function does wonders for road durability.

Moreover, geotextiles deal with water problems by getting rid of them. Non-woven geotextiles are especially good in high-moisture areas as they move the water and also stop the drainage systems from clogging. For instance, a report from Global Road Construction Trends (2023) pointed out that road built with geotextile-layered systems suffer only 70% of the erosion damage caused by floods and rains as compared to those constructed by traditional methods.

Advantages of Geotextile Fabric in Road Construction

Road construction using geotextile fabric offers multiple important advantages. To me, it has been a great help in soil stabilization, giving drainage a boost, and cutting maintenance costs in the long run. It is a water-related erosion prevention and road structure durability-enhancing method that guarantees a longer service life and great performance even in moisture-laden areas.

Road Construction with Geotextile Fabric Durability and Longevity

Geotextile fabrics have become synonymous with exceptional durability and longevity making them indispensable in constructing modern roads. It is because of their specific purpose to endure the extreme environment, heavyweight, and tension for a long time that they serve as a stable and effective infrastructure. The results from research are that when geotextiles are in the mix, the roads last longer because the maintenance is less and the degrading of the structure is postponed.

Chemical and biological resistance is one of the main contributors to the durability of geotextiles. Polypropylene or polyester synthetic geotextiles are the most common and they are made so that they do not absorb UV rays, corrosive substances, or microbes and thus the very nature of the fabric is not affected even when the time is long. For example, there are reports stating that geotextiles in drainage systems can last up to 50 years plus if they are well fitted and properly maintained.

Geotextiles’ Cost-Effectiveness

Road construction with geotextiles could be a great source of cost savings compared to traditional methods of construction. A research of the International Geosynthetics Society says that the use of geotextiles in a project can cut down on the costs of initial construction by 20-50% which varies according to the extent of the project and the materials that have been used. The savings are due to their reinforcing quality that repels the formation of roads with thick layers of aggregate and also saves the excavation process. Moreover, geotextiles contribute to the longevity of roads and the reason is that they prevent soil erosion, thus the repair frequency and repair cost are kept to the bare minimum.

In recent industry-reported data, it is said that geotextiles have cut down maintenance costs by 40% throughout the whole life cycle of a road. This is because there are so many failures and surface deformities less. A study done in India in 2022 about a highway project showed that the use of geotextiles instead of traditional construction methods resulted in long-term savings of around $500,000. Just as up to this day, the European infrastructure project has been proven to be so efficient in terms of cost because of reduced manpower and material when geotextiles are deployed.

Types of Geotextile Fabrics

Woven Geotextile Fabric

The fabrics of woven geotextiles are produced by the interweaving of two or more sets of yarns, which are generally composed of either polypropylene or polyester, thus resulting in a strong and durable product. The woven geotextiles, with their remarkable tensile strength, are frequently employed in areas where vast load distribution and strong reinforcement are required. These fabrics perform exceptionally well in heavy traffic and high-stress situations, e.g., road construction, retaining walls, and railway infrastructure.

The foremost benefit of woven geotextiles is their exceptional resistance to stretching and deformation under load. Market research indicates that the tensile strength of woven geotextiles can vary from 150 kN/m to even more than 300 kN/m, thus making them suitable for large-scale applications. Moreover, their low permeability facilitates efficient soil layer separation and stabilization, thus prolonging the life of engineered structures.

Non-Woven Geotextile Fabric

Non-woven geotextile is a material that is extremely adaptable and ranks high in the list of materials used in civil engineering and environmental applications. In contrast to woven fabrics, non-woven geotextiles are produced by the bonding of fibers through mechanical, chemical, or thermal methods, which results in a fabric that has very good permeability and filtration capability. This is the reason they are used in the areas of drainage, separation, and filtration in various infrastructure projects.

Non-woven geotextile fabrics are increasingly popular in road construction and landfill sites, as per the latest market research. For example, these fabrics are an essential component in subsurface drainage systems since they not only drain but also filter soil particles that would otherwise clog drainage pipes. The market for non-woven geotextiles is expected to grow at a compound annual growth rate (CAGR) of 5.4% between 2023 and 2030, with the growth being led by increased infrastructure development and the imposition of stricter environmental regulations.

Geotextile Fabric Installation Process

Geotextile fabric installation process starts with site preparation, i.e., the area has to be cleared and leveled. After that, I will slowly and cautiously unroll the fabric in the area that is prepared making sure that there are no any imperfections like wrinkles or folds. If it is necessary, to use more sheets, I will overlap the edges to keep the connection, and then I will use pins or staples to secure it.

Road Fabric Integration Best Practices

The incorporation of road fabric or geotextile fabric into the road construction and maintenance project spectrum must be carefully planned and then executed according to the methods proven to increase the efficacy of the fabric used. By proper installation the pavement life will be enhanced, the maintenance won’t be so costly and the load will be distributed better. Below are the main key points in the road fabric integration best practices:

Site Prep: The first step is to get the subgrade to the right grading and compaction degree with the removal of organic matter, stones, or waste that could cause trouble with fabric installation. – Research has found that a properly done subgrade can add up to 25% to the lifespan of the road.

Fabric Choice: Pick the right kind of geotextile fabric based on what the project intends to do, for instance, non-woven fabrics for filtration and drainage or woven fabrics for reinforcement and separation purposes. A case in point, a typical 6-oz non-woven fabric is commonly used for road drainage applications.

Seam Overlap: Avoiding soil migration is highly dependent on the proper overlap of the fabric. A minimum of 18 inches for low-volume roads and up to 36 inches in high-stress or poor-soil areas are recommended overlaps according to the industry standards.

Anchoring and Securing: To keep the geotextile fabric in place securely, use staples, pins, or weights to hold it down throughout the installation process. Areas that experience strong winds or heavy traffic will require more anchoring at 3-foot intervals along the edges.

Material Placement and Compaction: Carefully place aggregates or any other filling materials on the fabric without causing tearing or dislocation. The use of tracked loaders is advisable to decrease localized stress. Research has indicated that proper placement and compaction can cut the risk of early road surface deformation by nearly 40%.

Common Mistakes to Avoid

The use of geotextiles in road construction projects requires the identification and prevention of common mistakes that can hinder the performance and longevity of the project. The following are the main errors to be avoided, backed by the latest data and practices:

Improper Material Selection

A very common mistake is to select the wrong type of geotextile for the project. For example, the use of non-woven geotextiles in high-strength applications where woven geotextiles are needed can lead to inadequate support. As per a 2023 report by the Global Geotextile Market Review, the right type of geotextile will not only reduce the road base stress-tolerance by 30% but also help in reinforcing it.

Incorrect Installation Techniques

Installation faults like insufficient anchoring or overlapping can result in the geotextiles shifting or tearing. Proper overlaps, which are normally 12 to 18 inches in length according to the ASTM standards, will prevent the geotextiles from failing under the traffic loads. Studies indicate that improper installation can lead to a 20-25% decrease in the lifespan of geotextile-reinforced pavement.

Neglecting Site Preparation

Neglecting site preparation for the foundation layer is one of the factors that lead to uneven load distribution and water pooling. A 2022 study indicated that adequate site preparation which is comprised of debris removal and surface leveling reduces the chances of structural damage by 40%.

Overlooking Drainage Design

For the geotextile to work, there must be proper drainage. Poor drainage can lead to waterlogging and the consequence is the geotextile becoming less effective and the road surface deteriorating prematurely. The Pavement Engineering Research Group (2023) has provided evidence that properly installed drainage systems can trim down the maintenance costs by as high as 50% in a decade.

Case Studies and Success Stories

Real-World Applications in Road Construction

The use of geotextiles in road construction has been a game changer for the engineering field since it was able to eliminate or mitigate a number of problems such as soil stabilization, drainage, and erosion control. Geotextiles have become indispensable to today’s road infrastructure. For example, their application can be seen in the construction of not only highways but also rural roads where the subgrade’s load-bearing capacity is preconditioned. A 2023 publication of the International Journal of Geosynthetics reported that highways with geotextile-based systems have seen a drastic decrease of about 40% in maintenance frequency as opposed to traditional designs.

Soils with a lot of moisture can benefit greatly from the use of geotextiles as well. The Indian government for example, during the highway project from Mumbai to Goa, resorted to the use of non-woven geotextiles under the surface of the road to ward off flooding and get the ground well settled. The road was given a lifespan increase of almost 60% which in substitution displayed a remarkable decrease in the repair costs throughout the major part of its life. Likewise, a research project in the United States concluded that making use of geotextiles in road construction brought down construction costs by up to 25%, and this was mainly because of better soil compaction and less material consumption.

Impact on Infrastructure Stability

Geotextiles are a very effective asset in the fight against the deterioration of infrastructures, as they facilitate soil reinforcement, drainage, and erosion control. According to studies, the treatment of soils with geotextiles can boost their load-bearing capacity by 30%-40%, which means that the roads, bridges, and embankments built on these soils can be more stable. For instance, the usage of geotextile layers in highway construction prevents soil displacement and minimizes the occurrence of pavement cracks thus prolonging the lifespan of the infrastructure.

The latest reviews of infrastructure projects in Asia have indicated that the adoption of geotextile materials could lead to a significant reduction of around 25% in maintenance costs over the period of 20 years. Furthermore, geotextiles are a major factor in reducing the occurrence of structural failures in extreme weather conditions like heavy rains and floods since they control water flow and minimize soil erosion. The fact that geotextiles are able to improve overall ground stability in areas with tricky geotechnical conditions further emphasizes their importance in modern engineering.

Reference Sources

-

Anita Plastics Blog

- Title: Top 5 Advantages of Woven Geotextile Fabrics in Road Construction

- URL: https://www.anitaplastics.com/blog/geotextile-fabric-for-road-construction/

- This source discusses the benefits of woven geotextile fabrics, including soil stabilization, erosion control, and cost-effectiveness, making it a practical choice for road construction.

-

Wisconsin Transportation Bulletin

- Title: Geotextiles in Road Construction/Maintenance and Erosion Control

- URL: https://ltap.engr.wisc.edu/wp-content/uploads/2019/12/Bltn_016_Geotextiles.pdf

- This document provides a comprehensive overview of geotextile applications, including separation, drainage, filtration, and reinforcement in road construction.

-

Singhal Global Blog

- Title: The Importance of Geotextiles in Road Construction and the Different Types of Geotextiles

- URL: https://www.singhalglobal.com/blog/geotextiles-in-road-construction

- This source explains the role of geotextiles in improving soil structure, preventing erosion, and enhancing road durability, with a focus on different types of geotextile fabrics.

Frequently Asked Questions (FAQs)

What Distinguishes Woven from Non-Woven Geotextile Fabrics?

The differentiation between woven and non-woven geotextile fabric is mainly based on the method of production and the respective areas of application. Woven varieties are the strongest and provide the most effective support while non-woven ones come along with the best drainage and filtration features. Depending on the particular requirements of a road construction project, one particular type may be more appropriate than the other.

In What Ways Is Geotextile Fabric Used in Drainage Systems?

The fabric is very often used in drainage systems, such as french drains, to not only help water flow but also to guard against land erosion. The fabric does let water through but it is also a filter that holds back dirt and so helps in the soil’s integrity around the area and prevents drainage systems from being blocked. This makes it a necessary element of the effective practices of road construction.

What is the Significance of Geotextile Fabric in Soil Stabilization?

Geotextile fabric is very important for the stabilization of soil as it can separate and stabilize different soil layers which otherwise would mix up and be lost during downpour. It keeps soil in place and thus prevents ruts and erosion; this is especially so in the case of heavy loading like in parking lots and driveways. Geotextiles not only help the subgrade soil to bear load but also prolong the life and performance of the road surface.

Are Geotextiles Suitable for Landscape and Erosion Control Applications?

They are one of the most effective methods for managing landscape and erosion problems and that is why geotextiles are preferred in such situations. They will stabilize gradients, act as barriers against soil wash off, and control the flow of water over the ground in various construction projects. By implementing the use of geotextiles, the engineers can be assured that the soil shares the water drinking capacity of the area while at the same time remaining in its designated location, thus, reducing the need for erosion control measures in landscapes.