For today’s construction works, durability, environmental protection, and cost efficiency are the three critical factors that can hardly be ignored. The usage of geomembranes and liners have turned out to be the key factors through which the aforementioned good characteristics are obtained as they come up with new ideas and solutions that not only add to sustainability but also to efficiency. If you are in the process of waste containment, water conservation, or infrastructure development, then geosynthetics have provided you with the most advanced means in the form of a comprehensive solution to your problems. This article discusses the role that geomembranes and liners play in construction quality, the advantages provided by the former, and the reasons for the latter becoming the necessity in various industries. Get prepared to reveal the science and the practical uses of these revolutionary materials.

Introduction to Geomembranes

What are Geomembranes?

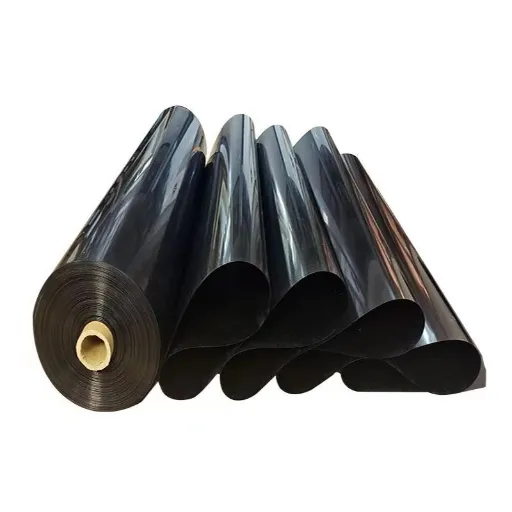

Geomembranes are impervious synthetic materials that have widespread applications as liners or barriers to obstruct the movement of fluids or gases. They are generally made from plastics such as High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), or Polyvinyl Chloride (PVC). Besides their excellent mechanical properties, geomembranes are also acknowledged as a barrier material on account of their durability, flexibility, and resistance to fire and water.

Market Growth: There is a big increase in the global geomembrane market from recent forecasts, but the growth will not be uniform across all regions; a CAGR of 7.4% is predicted for the period between 2023 and 2030, which is going to push the market size of the end of the decade to $4.5 billion. Progressive exodus of plastic waste in urban areas along with containment systems especially in the industry and water reservoir lining for agricultural use are some of the factors triggering the demand for geomembranes.

Importance of Geomembranes in Construction

Contamination and environmental issues are some of the problems that can arise from the construction site. Thus, geomembranes are a significant part of the construction process, especially for the environmental containment, structural integrity, and long-term durability projects. They are the main barrier in landfill caps, wastewater treatment, mining operations, and tunnel waterproofing. One of the noteworthy things about the global geomembrane market is that its size is going to be about USD 3.7 billion by 2028 with a CAGR of 9.5% for the years 2023-2028. The increase in demand for geomembranes signals the growing market for their diverse applications.

Key Capability: Among the most important aspects of geomembranes is that they are capable of greatly reducing leakage as well as eliminating contamination. An example of their role in landfill projects is that they prevent the hazardous leachates from entering the surrounding soils and groundwater thus complying with environmental regulations. Modern geomembranes are classified as high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), and polyvinyl chloride (PVC) and their chemical resistance and durability are excellent.

Types of Geomembranes

Other Types of Geomembranes

Linear Low-Density Polyethylene (LLDPE)

Due to their flexibility and elongation characteristics, LLDPE geomembranes are really appreciated and thus together with mining and waste management, they also get adapted to other sectors which require the changing of the ground movements. Their thickness and weight are less than that of HDPE liners so installation in difficult terrains becomes easier.

Polyvinyl Chloride (PVC)

PVC geomembranes are majorly seen in applications where the need for maximum flexibility is a must, like with water reservoirs, canals, and ornamental ponds. They have a high resistance to punctures and can be easily welded which renders them a cheap option for short to medium projects.

Ethylene Propylene Diene Monomer (EPDM)

The durability of EPDM geomembranes is exceptional. Adding to this, their high resistance to UV and weather makes them suitable for open-air applications like roofing systems, aquaculture ponds, and water reservoirs. Their adaptability of high deformation cannot compromise the waterproofing integrity due to the elasticity of the material.

Geosynthetic Clay Liners (GCLs)

GCLs are a composite material consisting of bentonite clay sandwiched between geotextiles. Being self-sealing and limiting seepage effectively, GCLs are usually used as liners for landfills and ponds. They are also getting a lot of attention for environmental applications since they come with a natural structure and have a smaller carbon footprint than the synthetic ones.

Comparative Analysis of Geomembrane Types

| Type | Key Characteristics | Applications | Considerations |

|---|---|---|---|

| High-Density Polyethylene (HDPE) | Superior chemical resistance, durability, and cost-effectiveness. Lifespan of over 20 years. Tolerates extreme temperatures (-40°F to 176°F) | Landfill liners, mining operations, wastewater management | Rigid nature can make installation challenging in some projects |

| Low-Density Polyethylene (LDPE) | More flexible than HDPE, shares chemical resistance properties, easier installation in intricate shapes | Agricultural ponds, canal linings | Lower tensile strength compared to HDPE |

| Polyvinyl Chloride (PVC) | High flexibility, easy fabrication, strong puncture resistance, easy welding | Water reservoirs, decorative ponds, smaller areas with irregular surfaces | Lower chemical resistance than HDPE/LDPE, may degrade under prolonged UV exposure |

| Ethylene Propylene Diene Monomer (EPDM) | Excellent flexibility, superior UV and weather resistance, high elasticity | Roofing membranes, aquaculture, decorative water features | Generally higher price than HDPE and LDPE, may be cost-prohibitive for large projects |

Applications of Geomembranes in Construction Projects

Application of Geomembranes in Landfills

Geomembranes are very important for today’s landfills, and their main use is to form an impenetrable wall which stops the bad leachate from leaking into the soil and groundwater around the landfill. These man-made liners are mostly made of high-density polyethylene (HDPE) because of its strength, ability to resist chemicals, and being versatile with different climate conditions.

Bottom Lining System

One of the major uses of geomembranes in landfills is the bottom lining system. In this case, the geomembranes are part of a multilayer structure that usually includes compacted clay liners, geotextiles, and drainage layers. Presently, different studies have confirmed that HDPE geomembranes have the lowest permeability rate that is quantified at less than 1×10⁻¹³ cm/sec, which plays a crucial role in providing long-term environmental safeguarding.

Use of Geomembranes in Water Containment

The importance of geomembranes in water containment systems is their ability to act as an effective barrier that prevents water loss and, thus, supporting the sustainability of resources. They are widely used in various applications such as reservoirs, canals, ponds, and facilities for wastewater treatment. These artificial liners are very much impermeable, hence giving the utmost protection against both seepage and contamination.

Market Projection: There is a rising global demand for geomembranes in water containment as a consequence of worsening water scarcity and the need for water management strategies that are friendly to the environment. Based on recent market analysis, the geomembranes market for this application is projected to grow at a CAGR of nearly 7% during the period from 2023 to 2030. In particular, the Asia-Pacific region is seeing rapid industrialization and urbanization which along with government support for water infrastructure are the main drivers of the region’s growth.

Benefits of Using Geomembranes

Geomembranes: Their Durability and Longevity

Geomembranes are designed to be extremely durable and to last for a long time, which are exactly the properties that the most demanding applications such as mining, industrial processes, and large water storage need. The continuously developing polymer technology has made it possible for modern geomembranes to be highly resistant to physical, chemical as well as environmental forces. An instance of this is the high-density polyethylene (HDPE) geomembranes, which are characterized by a long life expectancy of more than 20-30 years under proper installation and maintenance conditions.

🛡️ Resistance Properties

A study from 2020 mentioned that the geomembranes of HDPE are showing the best resistance to ultraviolet (UV) radiation, thermal degradation, and chemical exposure. Therefore, they are considered perfect for the applications such as tailings ponds in mining or waste containment systems that are exposed to the more severe environmental conditions.

💪 Tensile Strength

Besides, geomembranes are characterized by remarkable tensile strength, some of them arriving at the impressive figures of 25-30 MPa, thus guaranteeing their performance in terms of the ability to handle mechanical stress and pressure loads.

Sustainability and Environmental Impact

The use of geomembranes is undoubtedly one of the most effective tools protecting the environment and promoting sustainability in various industries. Their implementation in containment systems minimizes the chances of harmful pollutants leaking into the soil and water sources, thus protecting the ecosystems. To illustrate, recent statistics from the industry indicate that placing geomembranes in landfill waste management has been able to stop over 95% of the potential leachate contamination, this way the degradation of the environment is notably reduced.

♻️ Long-Term Sustainability

Also, the long life and durability of geomembranes are linked with resource consumption and waste production being less. Containment methods of the old school have to face much more replacements than geomembranes, which means that less production resources are needed and likewise, less emission of greenhouse gases resulting from that. It has been estimated that high-performing geomembranes can be effective for 30 or more years if the right conditions are maintained, which further gives them the status of the eco-friendly product.

Recent Advancements in Geomembrane Technology

Innovations in Geomembrane Manufacturing

Innovations in the manufacturing of geomembranes have come up with new and improved methods of production that aim at the dual enhancement of performance and sustainability. One of the significant innovations is the use of multilayer co-extrusion technology. With this method, manufacturers can obtain geomembranes made up of several layers with different functions. Each layer can be for a specific purpose that could be improved puncture murder, increased flexibility, or even enhanced chemical resistance. Importantly, multilayer co-extrusion gives durables with long life spans and low impacts on nature.

The other exception is the making of geomembranes from HDPE (high-density polyethylene) and LLDPE (linear low-density polyethylene) polymers. These materials have a remarkable resistance to stress cracking and can withstand the extremes of the environment for a prolonged time, thus being suitable for operations under the harsh conditions of mining and landfilling. As per the latest reports, HDPE geomembranes have experienced a significant rise in their life span and now they can last over 30 years with appropriate maintenance.

New Applications and Techniques

The recent advancements in the technology of geomembranes have made it possible to come up with entirely new applications in various industries. The market for floating solar panel systems is one such application area that looks very promising. Geomembranes are playing a significant role in these solar installations by providing floating bases, especially in lakes and reservoirs. According to research, the floating solar market worldwide is likely to experience an increase in its size at a compound annual growth rate (CAGR) of 28.9% from 2021 to 2028. This growth will be supported by the high efficiency of floating solar systems and the indispensable role of geomembranes in giving strong and water-resistant foundations.

⛏️ Mining Applications

Furthermore, the use of geomembranes in mining has been steadily increasing. They are being deployed in heap leaching methods for the purpose of providing liners that stop the chemicals from getting to the ground. A report published in 2023 is one of the sources that draw attention to the use of HDPE (High-Density Polyethylene) geomembranes in containment applications and the surprising 25% enhancement in their performance to prevent toxic metals in comparison with conventional materials.

Reference Sources

-

Civil Layer:

- Article: Geomembrane Trends 2025: What Construction Pros Must Know About the $3.69B Market

- This source discusses the advancements, applications, and market trends of geomembranes in construction, highlighting their importance in environmental protection, durability, and cost-efficiency.

- Source Link

-

Global Market Insights:

- Report: Geomembrane Market Size, Share & Global Report – 2032

- This report provides detailed insights into the geomembrane market, including its applications in construction, mining, and water management, along with growth drivers and challenges.

- Source Link

-

Mordor Intelligence:

- Report: Geomembranes Market Size & Share Analysis – Growth Trends and Forecast (2025 – 2030)

- This analysis covers the applications of geomembranes in construction, waste management, and water containment, emphasizing their role in sustainable infrastructure projects.

- Source Link

Frequently Asked Questions (FAQs)

❓ What are geomembranes and their application in construction?

A geomembrane is defined as a thin and flexible membrane liner that aims at controlling or reducing the flow of liquids within building sites. Its functions extend to, but are not limited to, landfill liners, mining, and water management, serving as a dependable wall to stop the flow of liquids and crack the earth while guarding the environment.

❓ What are the different types of geomembranes used in construction?

Construction sites employ a variety of geomembranes, among which are HDPE geomembranes, PVC geomembranes, and composite liners. Each of these types possesses distinct features, such as resistance to chemicals and elasticity, that render them fit for different purposes like liners for landfills and pads for heap leaching.

❓ How are geomembrane sheets installed in construction projects?

The procedure for the installation of geomembrane sheets systematically includes the preparation of the site, evaluation of the subgrade, and suitable arrangement of the geomembrane. Secure welding or gluing must be executed on the seams located between the sheets in order to form a barrier with low permeability that can hold liquids efficiently.