Geomembranes have proven to be the most effective and even sometimes the only solutions for water management and environmental protection. The liners, which are very strong and impermeable, are at the heart of numerous application cases, such as the construction of landfills, the erosion control through reservoir, pond and canal lining, among others. But what makes geomembranes so effective and how do they become a fundamental part of waterproofing projects? The present article will elaborate this and highlight the science of geomembrane technology, along with their benefits, applications, and the critical role of infrastructure and ecosystems protection that the geomembrane plays. Regardless of whether you are a construction professional, environmental engineer, or just someone who is curious about modern waterproofing techniques, the information in this guide will help you understand the reasons for the leading position of geomembranes in contemporary engineering.

Introduction to Geomembranes

What Are Geomembranes?

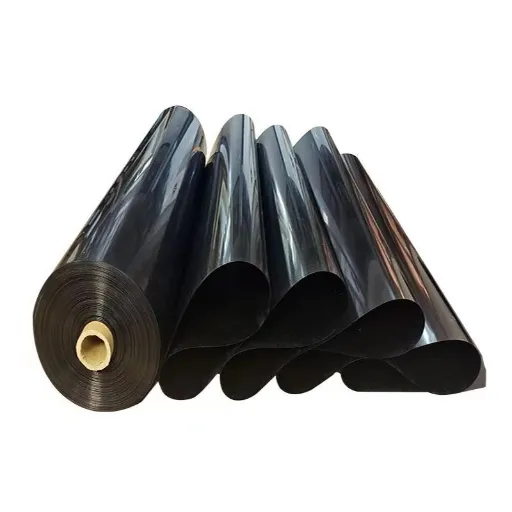

Geomembranes are non-permeable substances which have been specially developed for controlling the movement of fluids in a great number of applications. Their composition consists mainly of synthetic polymers like High-Density Polyethylene (HDPE), Linear Low-Density Polyethylene (LLDPE), Polyvinyl Chloride (PVC), or ethylene propylene diene monomer (EPDM), which act as the main barriers in the environmental, agricultural, and industrial projects.

The advanced liners boast of great longevity, resistance to chemicals, and tolerance to various weather conditions which is the main reason for their widespread use. For instance, in landfills, geomembranes function as base liners that stop leachate—the contaminated liquid—from getting into the groundwater. In the same way, in mining industries, geomembranes are used in tailing ponds for the safe storage of toxic materials.

Applications of Geomembranes

Landfill Liners and Caps:

Municipal and hazardous waste landfills make extensive use of geomembranes to avoid the contamination of soil and groundwater. Landfill liners made of High-Density Polyethylene (HDPE) with typical thickness of 1.5mm to 3mm, are very much in demand because of their durability and chemical resistance, thus managing leachate effectively and stopping the harmful seepage.

Mining Operations:

Geomembranes are used in heap leach pads, tailing dams, and storage ponds, assuring the containment of mining by-products and chemicals. Mining industry reports suggest that the containment efficiency of geomembranes in mining is over 95%, which as a consequence, depletes environmental risks to a great extent.

Water and Wastewater Management:

The geomembranes are placed at all points where the water is to be contained; reservoirs for drinking water, treatment for dirty water lagoons, etc. based on their non-leakage properties, allocation may be done. It has been found that PVC and LDPE geomembranes will achieve a water loss control efficiency of up to 98%, thus leading to better resource conservation in dry areas.

Aquaculture Ponds:

Geomembranes are a must in aquaculture for the construction of durable, non-toxic, and algae-resistant pond linings. HDPE and LLDPE geomembranes, which have a thickness of 1mm to 2mm, are used for the purpose of water quality improvement by ceasing the mixing of soil and pollutants with the water.

Benefits of Geomembrane Waterproofing

Cost-Effectiveness of Geomembranes

Due to durability, efficiency, and versatility, geomembranes are an economically feasible option for numerous infrastructural and environmental projects. Their long life greatly diminishes the costs of maintenance and replacement related to traditional approaches. For instance, high-density polyethylene (HDPE) geomembranes, characterized by excellent chemical resistance and flexibility, can last more than 30 years if the conditions are right. There are studies that have indicated that the use of geomembranes in landfill liners or water containment applications could lead to a project cost reduction of up to 50%.

The process for the application of geomembranes, however, is very quick and inexpensive and is therefore one of the main reasons for lower labor costs and less downtime. Among modern geomembrane technologies are also the use of prefabricated panels, which not only cut down on the time for installation but also on the chances of mistakes happening at the site. Through material science, for example, the development of textured geomembranes, strategies have been devised that not only compensate for high temperatures and moisture but give also excellent cost-to-benefit ratios. Accordingly, geomembranes are not just able to mitigate serious environmental problems but also generate significant savings and therefore are the right choice for economically conscious projects that are not willing to lower the quality and performance standards.

Environmental Protection

One of the major functions that geomembranes serve in environmental protection is by keeping pollution at bay and managing waste properly. These synthetic membranes find their place in applications such as landfill liners, mining operations, and wastewater treatment facilities. The global geomembrane market size was valued at about $2.6 billion in 2022 according to recent reports and it will witness a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030, which shows its growing importance in the sustainable practices.

The environment is significantly protected by geomembranes, one of their most important features being that they act as a barrier against harmful materials and pollutants. A case in point is the application of geomembranes in landfills that has decreased the likelihood of leachate penetrating the ground and polluting the water supply. Research shows that landfill liners made of geomembranes can cut leachate outflow by as much as 99%, thus enabling the adoption of safer waste management methods.

Geomembrane Waterproofing Systems

Waterproofing Membrane Systems Overview

The waterproofing membrane systems are an actual barrier made of various materials and are heavily deployed in construction and infrastructure projects to protect the structures from the destruction caused by water infiltration. These systems have a wide range of applications such as roofing, basement waterproofing, tunnels, bridges, and even water reservoir projects. There are two primary categories of waterproofing membranes: sheet-based membranes and liquid-applied membranes, each has its own distinct benefits that depend on the specific project needs.

Sheet-based membranes like thermoplastic PVC or HDPE are pre-formed and maintain a consistent thickness. They have a high level of resistance to water, chemicals, and punctures which makes them very suitable for large-scale applications such as landfill liners or below-ground waterproofing. Liquid-applied membranes that are applied on-site, on the other hand, create a barrier that is seamless and fully adhered and that takes on the surface shape. This flexibility guarantees they meet the needs of irregular or complex surfaces with total coverage.

Geomembranes of High Performance

Modern waterproofing and containment systems, high-performance geomembranes to be the very core, have been designed to deliver excellent durability and environmental protection. These synthetic liners, which are typically made from materials such as high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), are dependable barriers to water, chemicals, and waste leakage in industrial and environmental applications.

One of the most important advantages of geomembranes is their excellent resistance to chemical degradation, UV light, and punctures. Thus, they are often used for hazardous waste containment, mining activities, and landfill liners. Research indicates that, for example, HDPE geomembranes can have a service life of over 36 years with regular use, while some studies even consider their durability to be longer in controlled environments.

Installation Best Practices

Preparation and Site Assessment

The installation of geomembrane liners is a very important and very costly process that should be well-prepared and very carefully assessed at the site. The performance and durability of liners largely depend on the preliminary site assessments done by professionals. A detailed site survey is conducted as a part of the process, in which the soil’s stability, geology, risk to the environment, and water conditions are among the factors reviewed. A geotechnical investigation is sometimes necessary to reveal the condition of the ground, i.e., to detect any problems like sharp stones, holes, or landslide-prone areas that could affect the liner badly.

One important factor of the preparation is the cleaning and leveling of the area where the installation is going to take place. The surface has to be free of any dirt, stones, and anything that would not allow it to be smooth and clean. Industry standards say that even tiny pebbles or bumps can generate the liner’s stress points which can lead to cuts or breaks in the liner. It is better to place a geotextile underlay to ensure even more safety in case of an area with bad or unequal surfaces, thus, prolonging the life of the liner and minimizing the chances of damage.

Installation Techniques for Geomembranes

Surface Preparation:

The installation needs the subgrade to be thoroughly prepared beforehand. Making the surface flat and hard is part of the process to get rid of sharp objects, dirt, or rough areas that might puncture or damage the liner.

Unrolling and Placement:

Geomembranes come in large rolls most of the time. So during unrolling and placement, the manufacturers caution that the geomembranes should be smoothly unrolled and positioned strictly according to the design specifications while taking care of the installation site. The general rule is that panels of the geomembrane are aligned with the major wind directions for reducing stress on the material during the installation phase.

Anchor Trenches and Ballast:

To stop shifting, geomembranes are mostly anchored in trenches dug along their perimeter. Use of ballast materials like bags of sand or stones may also be done in a planned way to keep the geomembrane in position, especially when windy.

Quality Assurance and Testing:

A high-quality seam is only achieved through the application of comprehensive testing that professionally assesses the internal quality and strength of the liner. Testing is done for quality control through vacuum box testing, air pressure testing, and destructive sampling done to find any faults or leaks. It has been found that projects with a solid quality control plan have post-installation failure rates that are more than 70% lower than those without.

Protective Layers:

The geomembrane can be protected against UV radiation, tears, or drastic temperature shifts by the use of protective layers like geotextiles, soil covers, or concrete. These layers not only save the life of the liner but also make it stronger to withstand tough conditions.

Case Studies and Success Stories

Successful Applications in Construction

Geomembrane systems have been remarkably successful in different construction works, especially in waste management, mining, and water resource management. One of the main uses for them is in landfill liners and caps. Geomembrane liners are said to be present in almost 70% of the landfill projects worldwide according to recent statistics, thus, preventing the leakage of the waste and the generation of contaminated surrounding water and soil. Their impermeability, chemical resistance, and durability are the main reasons for their effectiveness.

One more successful case is in the case of tailings storage facilities in the mining sector where geomembranes have been a good choice. With the modern technology of geomembrane, a very high efficiency of containing the toxic by-products of mining has been witnessed, and some research indicates a 99% containment rate when the geomembrane is installed and tested properly. Likewise, geomembrane linings are used in the construction of artificial lakes and reservoirs. The water would not be able to seep through, thus, these liners would lose less water and the underlying soil structures would be protected, and thus, the water storage solutions in arid regions which suffer from scarcity will become more efficient.

Environmental Remediation Projects

In the environmental remediation projects, geomembranes are the most important players since they are the only solution that is reliable for the arrival of the containment, protection, and restoration efforts. These synthetic barriers are found in almost every application that is associated with landfill liners, wastewater treatment plants, and hazardous waste containment systems. Moreover, by substantially reducing the risk of soil and groundwater contamination, geomembranes prove their worth in combating environmental issues.

For instance, at the Kalamazoo River Superfund site in Michigan, where a huge project is going on, geomembranes have been introduced in the process of the safe containment and remediation of Polychlorinated Biphenyls (PCBs) contamination. The leakage of Polychlorinated Biphenyls (PCBs) contamination has been the cause of over 1.2 million cubic yards of PCB-contaminated sediment being cleaned up.

Reference Sources

-

ReportPrime – Geomembrane Liner Market Analysis

This source discusses the target market for geomembrane liners, including industries like mining, waste management, water management, agriculture, and construction. It provides insights into the applications and demand for geomembrane waterproofing.

Source Link -

DataIntelo – Specialty Geomembranes Market Report

This report highlights the versatility and durability of specialty geomembranes, emphasizing their use in construction, agriculture, and mining sectors. It offers a detailed analysis of market trends and applications.

Source Link -

Geosynthetic News Australia – Industry Insights

This publication provides insights into the geomembrane industry, including its applications, audience, and advancements. It is a reliable source for understanding the role of geomembranes in various sectors.

Source Link

Frequently Asked Questions (FAQs)

How do HDPE geomembranes stack up against other varieties of geomembranes?

In different applications, HDPE geomembranes stand out due to their premium tensile strength and long life. When it comes to other geomembranes, HDPE is a clear winner due to its superior resistance to both chemicals and UV rays. This has made it the top material for waterproofing in extreme environments and prolonged periods.

What are the properties of HDPE that suit it for geomembrane waterproofing?

HDPE’s properties that make it most suitable for geomembrane waterproofing include its high tensile strength, chemical and moisture resistance, and malleability. These qualities work together to allow HDPE geomembranes to resist and recover from environmental conditions and thus be a faithful barrier against water and other liquids.

How are geomembranes applied in waterproofing projects?

Geomembranes are mostly applied through fusion techniques resulting in the making of uninterrupted joints among which the waterproof barrier is preserved. The whole installation scenario needs the utmost substrate preparation and the sheets of the geomembrane to be accurately handled so that the waterproofing system’s integrity is not lost.

What are the top reasons for protective geomembrane adoption?

The definite reasons for protective geomembrane use are multiple, such as long service life, environmental stressor resistance, and less maintenance. These characteristics make them an efficient solution for waterproofing applications and cut down the needs for repairs or replacements not too often.

Is it possible to use geomembranes along with geotextiles?

It is possible for geomembranes to be employed together with geotextiles, not only to boost the performance of waterproofing systems but also to extend their life. The joining acts as an additional layer for punctures and aids in draining which renders the system more efficient in blocking water infiltration and in keeping the structure’s strength.