Geomembrane sheets have brought about a significant change in the way civil engineers consider and plan opposite critical infrastructure projects, and the new industry applications they offered are just a part of this change. Their ability to provide all these advantages across different sectors confirms the significance of these materials. To be specific, geomembrane sheets are now considered essential materials in landfill lining, reservoir seepage prevention, and road construction among others. This guide is meant to discuss the major applications, advantages, and considerations for the use of geomembrane sheets, thus enabling you to draw the necessary insights for your next project. On the other hand, if you are planning to overcome environmental and structural challenges while improving performance, this article is no doubt your all-in-one resource.

Introduction

What Are Geomembrane Sheets?

Geomembrane sheets are artificial membranes that have no holes at all and are made of a combination of materials that are mostly non-degradable and are used for environmental and civil engineering. These membranes are usually made of high-density polyethylene (HDPE), low-density polyethylene (LDPE), or linear low-density polyethylene (LLDPE) polymers, but they can also be made of other plastic types. The reason behind these membranes’ widespread use and long life is their ability to stop the movement of fluids or gases from one place to another.

With the mechanical strength, chemical resistance, and durability of geomembrane sheets being their main reasons for being highly valued, the industry has kept on expanding and these sheets are still being used in ways such as the construction of liners for landfills, ponds for treating wastewater, and the lining of reservoirs and mining sites as well as the control of erosion. It has been found in studies that HDPE geomembranes, for example, can have a lifespan of 50 years provided that they are installed properly and maintained regularly, thus being able to perform even in extreme environmental conditions.

Importance in Civil Engineering Projects

The use of geomembrane sheets in civil engineering projects is made possible by their providing of environmental protection and structural stability. Among the fields where their application is most common are landfill liners, wastewater containment systems, and mining operations that prevent the contamination of soil and groundwater. Based on the recent reports from the industry, the global geomembrane market was valued at about USD 2.2 billion in 2022, with a projected compound annual growth rate (CAGR) of more than 7% from 2023 to 2030, which is a clear indication of their increasing demand across different sectors.

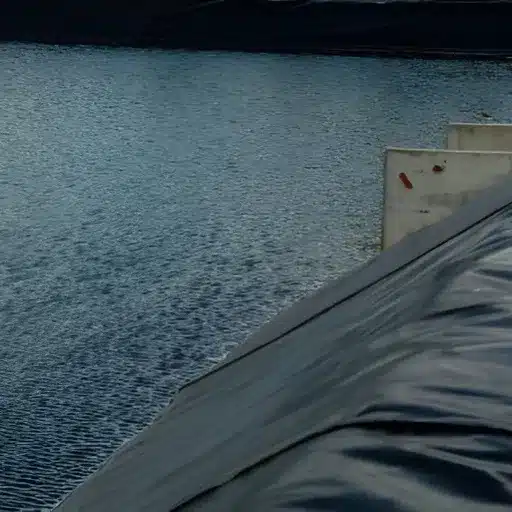

One of the major benefits that can be mentioned of geomembranes in civil engineering is their excellent tensile strength, which allows them to endure considerable stress without breaking. Large infrastructural projects such as dams, reservoirs, and canals often depend on the use of HDPE or PVC geomembranes for these materials’ impermeability, thus making sure that water is not lost for a long time. Moreover, in the area of transportation infrastructure, geomembrane barriers are applied under roadbeds to both prevent soil erosion and increase the road’s durability.

Applications of Geomembrane Sheets in Civil Engineering Projects

Use in Landfill Liners and Covers

The usage of geomembrane sheets in today’s landfills is indispensable. They serve the dual purpose of liners and covers in waste disposal which manage the waste in a proper manner and more importantly, keep the environment around the landfill clean. The liners that are made out of geomembranes with HDPE (High-Density Polyethylene) being the main material, give an impermeable barrier. This barrier doesn’t allow leachate, which is the contaminated liquid that results from the waste being decomposed and water flowing in, to get into the soil and groundwater. Thus, this practice is very important for meeting the standards set by the government and also, protecting the flora and fauna around the landfill.

The HDPE geomembranes are very strong, and they have great chemical resistance and very low permeability, which are the characteristics that make them perfect for landfill applications. Research shows that liners made of geomembrane and installed properly can get the permeability of as low as 10^-12 cm/sec. This certainly means that they are making a strong barrier. On the other hand, the technology of materials has improved to the extent that now they can produce thicker liners, which are typically between 1.0 mm and 3.0 mm, giving more power and longer life to them.

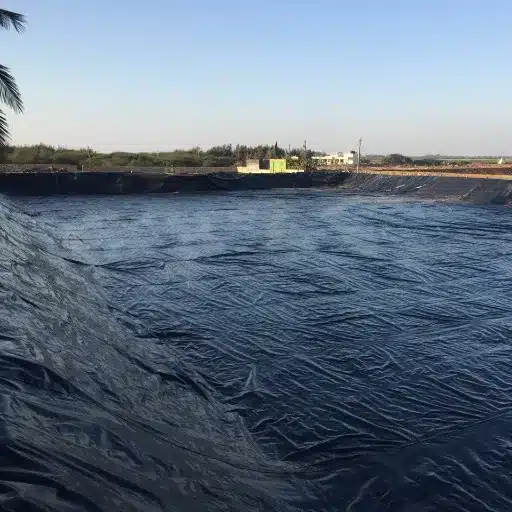

Geomembranes in Construction

Geomembranes have become a vital component in the modern building industry because of their adaptability and robustness. These synthetic membranes, usually composed of high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), are used as non-permeable barriers in many different applications. Their major role is to keep liquids and gases from leaking out or to hold them in. This is one of the reasons why they are so valuable in projects like landfills, water reservoirs, mining, and building foundations.

In construction, geomembranes are extensively used for waterproofing and soil contamination prevention. For instance, in landfill applications, double-lined HDPE geomembranes prevent leachate containing toxic substances from reaching groundwater. A 2022 study showed that the permeability of HDPE geomembranes is less than 0.05% and their service life is more than 50 years if they are properly installed and maintained. Moreover, they are used in building foundations as vapor barriers which prevent the entry of moisture that might cause structural damage or mold growth.

The Benefits of Geomembrane Sheets for Civil Engineers

Cost-Effectiveness and Long-Term Savings

Geomembranes are an absolute winner when it comes to cost-effectiveness, and that’s why they are considered an essential part of the investments made in civil engineering works. They are so durable and resistant to all environmental factors like UV rays, chemical degradation, and even mechanical stress that the need to replace or repair them often is diminished to almost nothing. For example, if one installs high-density polyethylene (HDPE) geomembranes at a place where conditions are perfect, they can expect these membranes to last over 30 years, and during this time, they will not have to spend money on maintenance.

Another factor that adds to the economic value of geomembranes is that their installations usually result in less material waste than the traditional solutions such as compacted clay liners. The industry’s estimates say that dealing with the installation of geomembranes in water containment and landfill applications can have savings in project costs by up to 50%. This is all due to the fact that less labor and material are required.

Enhanced Environmental Protection and Sustainability

Geomembranes are a critical factor in the protection of the environment and sustainability as they mainly recognize the eco-(friendly) impact of their recycling and conserving natural resources. By acting as a strong and non-negotiable barrier to toxins, they keep preventing the creeping of the poisonous substances into the soil and water supplies – a situation, which is, in fact, very important in the case of landfills, mining operations, and chemical containment. Research reports have revealed that geomembranes have the capacity to maintain a leakage rate as low as 1×10⁻¹² cm/s, hence, a great reduction in the environmental pollution risk compared to the clay liners.

Furthermore, the use of geomembranes is a practice that indirectly promotes the realization of the objectives of sustainability through the reduction of water wastage and the improvement of resource efficiency. For example, pesticides in agribusiness, usage of geomembrane liners in agricultural ponds and reservoirs has been indicated to reduce water loss due to seepage by up to 98%, thus keeping precious freshwater intact in dry areas. Moreover, the latest manufacturing technologies and techniques such as the development of geomembranes made of recycled materials have contributed to the eco-friendliness of these products. Not only do these technological advancements lessen the carbon footprint connected with the process of production but also they make the project’s longevity even more attractive as they are central to the engineering of sustainable practices in the long run.**

Best Practices for Installing Geomembrane Sheets

Pre-installation Site Preparation

Site Survey and Assessment

The site survey should be conducted very carefully so that all irregularities and risks are detected. The task of such a survey is mapping all underground utilities, evaluating the surface’s geometry and determining locations of surface water stagnation during rainy seasons. Some studies have shown that if the surface is not properly prepared, a geomembrane may lose up to 30% of its effectiveness.

Grading and Leveling

The site must be well-graded, compacted, and leveled. The grading procedure should ensure no sharp rocks, debris, or vegetation that could puncture the geomembrane are left on the surface. Current field data indicate that improper surface preparation is responsible for 90% of geomembrane failures, thus the need for grading is underlined.

Clearing the Area

Vegetation, roots, and all organic matter must be removed from the area. Clearings like small trees or shrubs that are hard to get rid of will cause geomembrane to decay through their maturity or regrowth. Surface clearing leads to better adhesion of the material to the ground and hence the risk of damage is lower in the long run.

Techniques for Proper Sealing and Welding

Extrusion Welding

This technique makes use of molten plastic to bond the overlapping geomembrane sheets. It is very advantageous for repairing and doing so precisely around intricate shapes like pipe penetrations that need detailing. The extrusion weld has to be done at a temperature which is controlled—normally between 400°F and 500°F—to avoid degradation of the material. Research indicates that the extrusion welds improperly done may reduce the strength of the bond by as much as 30%, resulting in unexpected failures.

Fusion Welding

Fusion welding utilizes a machine that generates both heat and pressure in order to melt and bond the overlapping geomembrane sheets. This method is widely accepted in the industry since its speed and efficiency makes it very suitable for applying on larger flat surfaces. Advanced fusion welders perform dual-track welding, which results in two sealed seams with an air channel in between that serves for non-destructive testing. Studies show that fusion welding can attain seam efficiencies of up to 90% of the material strength, provided that the right conditions are observed in conducting the process.

Quality Control and Testing

Quality control measures must be established properly in order to guarantee weld integrity. Among the non-destructive testing techniques used to find weak spots are air channel testing and ultrasonic testing. Destructive testing methods, such as peel and shear tests, are applied to accept weld strength, which is usually above 80% of the parent material’s tensile strength.

Reference Sources

-

Geomembrane Sheets in Construction – Geofantex

This source discusses the flexibility and durability of geomembrane sheets, highlighting their use in sealing and protecting structures from water and environmental contaminants.

Read more here -

What Is Geomembrane Sheet and Its Applications – BPM Geomembrane

This article explains the critical role of geomembrane sheets in fluid and gas containment, particularly in geotechnical and environmental engineering.

Read more here -

The Importance of Geomembrane Liners in Water Management – Western Liner

This blog highlights the use of geomembrane liners in preventing water loss and contamination, emphasizing their durability and applications in reservoirs and wastewater treatment.

Read more here

Frequently Asked Questions (FAQs)

What is the installation process for a geomembrane liner?

The installation procedure of a geomembrane liner usually requires the preparation of the site, which includes grading and compacting the ground surface, and then the installation of the geomembrane sheets. After that, seams are welded or sealed to make the structure impervious to water. Proper installation is of utmost importance to the performance and life of the liner, and it usually requires skilled workers to observe the best practices.

How do geomembranes contribute to environmental protection?

Geomembranes are non-biodegradable materials that contribute significantly to environmental protection by impeding liquid migration and regulating pollution. They are often used in waste disposal areas and landfills to isolate hazardous waste and secure the access of underground water to the contaminated area. Their toughness and potency do not wear off and, therefore, they are effective over time, thus, contributing to the management of the environment in a sustainable manner.

What are the advantages of using HDPE geomembrane sheets?

HDPE geomembrane sheets are known for their strength and durability, they can also resist UV radiation, and they are very low in permeability, all these properties combined make them the best choice for containment applications. They are also affordable and can be produced in various thicknesses to suit the particular project requirements. Furthermore, HDPE is compatible with different geosynthetic products allowing for its use in a wide range of applications.