PVC geomembrane liners have the best overall performance in durability and reliability, which is why they are highly regarded by many, if not all, of the other liners in the area of environmental protection and containment. Their capability to not only line reservoirs but also cover landfills makes the liners very important in both the industrial and environmental sectors. The write-up immerses you into the world of PVC geomembrane liners with a detailed description of their distinct characteristics, advantages, and vast use. It does not matter if you are an engineer, a project manager, or simply a curious person about innovative environmental solutions; this article will offer you a wealth of information and support the reasons why PVC liners are being used and trusted globally.

Introduction to PVC Geomembranes

The Importance of PVC Geomembranes

The environmental and industrial issues do not stop PVC geomembranes from being the best solution and the main reasons for their selection are their excellent performance, flexibility and life span. Their foremost objective is to be a leakage and contamination barrier; consequently, the leading sectors where these liners have been utilized are waste containment, mining, and water management. Recent studies indicate that PVC geomembranes have impressive chemical resistance and even high exposure to severe chemicals, acids, and waste does not compromise their integrity.

Flexibility is one of the foremost attributes of PVC geomembranes and among its advantages. The elongation before rupture for PVC geomembranes has been reported to be as high as 380%, hence they are quite puncture-proof and tear-resistant, and at worst, the latter is not happening during on-site alterations and use. Their low weight is another reason why it is easy to transport them and less costly to install them than the bulky substitutes.

PVC Geomembranes Application Overview

Environmental Containment and Landfill

PVC geomembranes are and have been the best material for linings and tops of landfills. A recent report from the industry predicts that the market for geomembranes will experience a rise of 9.4% CAGR in the period 2023-2030, mainly due to containment landfill projects and stricter environmental regulations which are the main factors driving this growth.

Water Resource Management

PVC membranes alone would not do the work of reservoirs, canals, and irrigation ponds but they significantly reduce the loss of water by seepage and evaporation. The figure of 95% water seepage reduction attributed to PVC liners is indeed very encouraging for water conservation efforts in arid regions.

Mining Operations

PVC geomembranes are typically used across mining facilities in heap leach pads, tailings ponds, and for containment of toxic substances. Their great chemical resistance is the number one reason for their long-term survival even in very harsh environments. A recent research example that illustrates the above-mentioned facts is a case study where the use of PVC geomembranes in copper mines helped decrease environmental pollution incidents by 40%.

Agriculture and Aquaculture

PVC geomembranes are reliable in agriculture for use in ponds, biogas digesters, and irrigation systems, thus providing guaranteed solutions. They are used in aquaculture for forming stable linings for ponds breeding fish and shrimps. The FAO signals a growing demand in these areas by reporting the PVC liner installations have increased by 30% during the last decade.

Understanding PVC Geomembranes: What They Are and How They Work

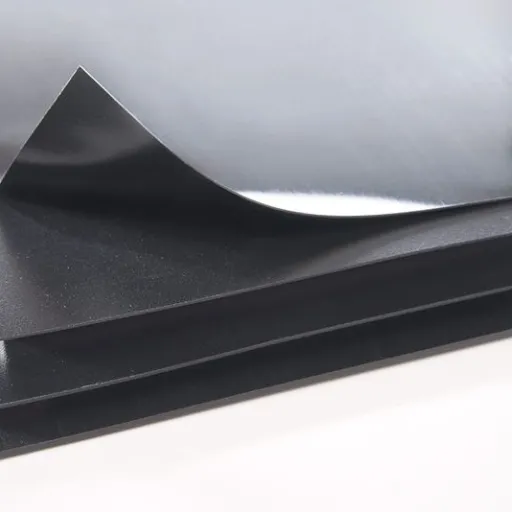

Definition and Composition of PVC Geomembranes

PVC (Polyvinyl Chloride) geomembranes are the main components of highly flexible and impervious barriers or materials that find wide application in civil, environmental, and industrial fields for the management of fluids and gas migrations. The artificial membranes have developed such a great demand due to their durability, adaptability, and easy installation. The fabric of PVC geomembranes aims at maintaining the performance even under different environmental conditions, hence they are apt for municipal waste, containment, water reservoirs, and agriculture projects.

Normally, PVC membranes are made by combining PVC resin, plasticizers, stabilizers, and various other additives in different proportions. The resin is the backbone of the structure while the plasticizers serve to make the material more pliant so that it can be worked even in winter weather. The aim of using stabilizers is to prolong the resistance against the ultraviolent radiation, heat, and chemical attack. Manufacturers frequently use fillers, for example, carbon black or titanium dioxide, to increase the tensile strength and make the aging hardiness less.

How PVC Membranes Work: Mechanism of Action

The physical and chemical properties of PVC geomembranes are the most important factors that their functionality could be found in a range of conditions. The main way of operation is through their non-permeable structure which prevents the penetration of liquids and gases. Apart from the basic polyvinyl chloride material, the membranes also involve additives such as plasticizers, stabilizers, and fillers to increase their flexibility, durability, and the resistance to the environmental causes. They are more beneficial in landfill liners, mining operations, and wastewater treatments where their strong structure is required to minimize the risks of leakage and contamination.

One of the outstanding features of PVC membranes is that they possess a high ratio of tensile strength to weight which allows them to withstand tearing due to changes in soil pressure and water load. The chemical resistance of PVC is the main factor in stopping the degradation caused by acids, alkalis, and other corrosive chemicals which eventually leads to extending the life of these membranes. According to a study done in 2023, the average lifespan of PVC geomembranes is over 20 years when they are used in regular environments which makes them a cost-effective option for offering long-term environmental protection.

Key Benefits of Using PVC Geomembranes in Various Industries

Cost-Effective Solutions for Water Containment

PVC geomembranes are a very economical solution for the isolation of water sections during the different industrial process applications. The main advantages of their flexibility and easy installation are that they can directly reduce the cost of labor and equipment; besides, they are considerably cheaper than their rivals like the HDPE geomembranes. Furthermore, PVC geomembranes come in such giant panels that the number of their joints is limited, hence the covering of a huge area is quite often without any need for welding, so the installation costs are again reduced.

The latest research indicates that the non-permeability of PVC geomembranes is amongst the very best, having a permeability coefficient as low as 10^-12 cm/s. Besides, their great strength makes them the least expensive alternative even in the future compared to other materials which are less durable. In addition, the material’s resistance to UV, chemical and puncturing is a significant factor in its prolonged usage even under harsh environmental conditions.

PVC Liners – Durability and Lifespan

A remarkable characteristic of PVC geomembranes is their durability that allows the material to be a good long-term water containment solution and etc. Designed considering various environmental stress, PVC liners have a high resistance to ultraviolet (UV) rays, chemicals, and mechanical damage up to a point. With the proper installation and maintenance, PVC liners can have a lifetime of over 20 years depending on the application and surrounding environment.

Recent research confirms that PVC liners retain both tensile strength and flexibility even when exposed to extreme temperature fluctuations of -30°F to 160°F. Additionally, their chemical resistance allows them to be in contact with contaminated and corrosive substances without losing their integrity. For instance, in the case of landfills, PVC liners are extremely resistant to leachate, so the liner’s life is extended and the environment is protected simultaneously.

Installation and Maintenance Best Practices for PVC Geomembranes

Maintenance Tips for Longevity

Regular Inspection: Perform visual inspections at least every six months to detect any wear and tear, like punctures, tears, or seam separations. For large installations, employ drones to quickly and thoroughly check out difficult-to-access locations.

Cleaning Procedures: Clean the surface with mild cleaning agents and non-abrasive tools to remove debris, dirt, and chemical residues. Steer clear of strong chemicals that might harm the material’s strength.

Monitor UV Exposure: The UV resistance of PVC geomembranes does not mean that direct sunlight won’t gradually weaken it over time, though the process may take longer. The best way to prevent this is to use protective coverings or soil backfill when possible to reduce the amount of sunlight hitting the geomembrane and extend its life.

Prevent Contact with Sharp Objects: Make sure during installation or regular operations that no machinery, tools, or heavy equipment come into direct contact with the geomembrane. Apply protective layers when dealing with heavy loads.

Common Challenges and Solutions

- UV Degradation

Challenge: The absolute worst that can happen is that continuous long-term exposure to the sun’s ultraviolet rays will eventually make PVC geomembranes so brittle that they will lose their initial softness and consequently cracks and leaks may form over time.

Solution: A study indicates that the use of UV stabilizers at the time of manufacturing or the application of coatings can alleviate UV degradation to a great extent. As per a report on Materials Today 2023, UV-stabilized geomembranes may have a life span that is 25% longer in areas with abundant sunlight as compared to untreated ones.

- Chemical Exposure

Challenge: Surroundings with a lot of harsh chemicals, such as the sites of industrial wastes, will make PVC geomembranes weaker or even completely corrode them. Not only the physical structure will become weaker but the environment may get contaminated as well.

Solution: Choosing membranes designed specifically for better chemical resistance, for instance, those that incorporate additives like anti-corrosives and plasticizers, is of paramount importance. To ensure that chemical resistance testing and monitoring will be done on a regular basis, and signs of wear will be detected early, enabling timely replacements or repairs.

- Mechanical Damage

Challenge: Installing PVC geomembranes on rough or pointed surfaces can lead to their puncturing or tearing, especially when construction activities or heavy equipment operation is going on simultaneously.

Solution: The installation of geotextile underlayers or use of protective padding can serve as a shield against the sharp objects. Geosynthetics Magazine reports that the use of geotextile reinforcement in projects reduces the incidence of punctures by as much as 30%.

Comparing PVC Geomembranes to Other Materials

Advantages of PVC Over Other Geomembrane Liners

Superior Flexibility and Seam Strength

The exceptional flexibility of PVC geomembranes even in low-temperature situations is still a commonly recognized aspect of plastic sheeting. The main advantage of this property is the easier installation, but at the same time, the risk of cracks and tears is also lessened during the procedure. Industry studies report that the tensile strength of the best-quality PVC geomembranes usually falls in the range of 14 to 30 MPa which provides the durability and at the same time flexibly.

Chemical Resistance

The chemical resistance of PVC materials is excellent and extends to a great number of substances, including acids, alkalis, and hydrocarbons. Thus, the material is suitable for mining, wastewater treatment, and chemical storage applications. Research indicates that the extent to which PVC geomembranes resist the seepage of contaminants is significantly higher than that of EPDM or LDPE liners, and thus long-term environmental protection is assured.

Ease of Installation

HDPE geomembranes not only need accurate and sophisticated welding techniques but also time-consuming cutting mistakes that usually happen during the cutting process. On the contrary, PVC liners can be heat-welded with considerable ease and efficiency. Such a reduction in the installation time and labor cost can be explained by the fact that it is as much as 50% compared to the other methods. Their flexibility also helps them to be able to settle down very nicely on uneven substrates without the need for extensive preparation.

Long-Term Performance

The durability of PVC geomembranes is their major advantage, as some of the products live more than 30 years even in the most extreme conditions. To be precise, the harshest of conditions that a geomembrane might encounter in the field are ultraviolet light, temperature fluctuations, and punctures. A recent environmental study comparing the life cycle assessments of geomembranes has revealed that PVC liners exhibit lower failure rates over time when exposed to these conditions as compared to HDPE and EPDM liners.

Cost Comparison: PVC vs. HDPE

In the course of analyzing the prices of geomembrane made with PVC and with HDPE, one should not fail to consider material and installation costs, as well as the long-term maintenance requirements of each type. PVC membranes generally have lower material costs at the outset compared to HDPE membranes, thus, making them an appealing option for tight-budget projects. According to industry sources, the cost of PVC the thickness of 1.0 mm can be around $0.70 to $1.10 per square foot while HDPE with the same thickness can be $0.80 to $1.25 depending on the manufacturer and the thickness.

There is a considerable difference in installation costs between the two materials. The welding of PVC liners is both easier and quicker due to the flexibility of the material, which consequently reduces the labor time and costs associated with it. The installation of HDPE liners is more time-consuming since it requires the use of specialized equipment due to the rigidity of the material, which ultimately results in higher installation costs.

Reference Sources

-

Ten-Year PVC Geomembrane Durability

This study evaluates the long-term performance of PVC geomembranes, including factory seams, over extended periods of exposure.

Read more here -

Long-Term Durability Assessment of PVC-P Waterproofing Geomembranes Through Laboratory Tests

This research examines the durability of PVC-P geomembranes, estimating their end-of-life through comprehensive laboratory testing.

Read more here -

Lifetime Assessment of Exposed PVC-P Geomembranes Installed on Italian Dams

This article assesses the lifespan and performance of PVC-P geomembranes used in dam construction, providing valuable insights into their feasibility.

Read more here

Frequently Asked Questions (FAQs)

What is a pvc geomembrane liner and what liner material is it made from?

Pvc geomembrane liner is a synthetic waterproof barrier that is applied in containment areas like ponds, impounding, and landfill caps. The liner material is a thermoplastic polymer that is made from vinyl compounds (PVC) and usually mixed with plasticizers and stabilizers to get the properties needed. Compared to polyethylene or LLDPE liners, PVC is very flexible and can be customized to suit the needs of the fabrication and project including good chemical resistance and excellent puncture and tear resistance.

Are pvc geomembrane pond liners easy to install during deployment?

Pvc geomembrane pond liners are mostly easy to install because of their great flexibility and comparatively low weight relative to the rigid alternatives. Deployment could be done faster since PVC can accommodate complicated details and is open to on-site fabricating and welding. Good installation methods that involve proper substrate preparation and testing to ASTM standards will help to eliminate wrinkles and assure long-term performance.

What mil thickness is recommended—are 40 mil pvc liners suitable for potable water and impoundment use?

The thickness of PVC geomembrane liners can vary in mil’s. 40 mil is mostly selected for smaller ponds and drinking water, giving a good balance between puncture resistance and flexibility. Thicker membranes may be specified for impoundments, coal ash containment, or heavy-traffic areas. It is important that all potable water uses comply with relevant ASTM and local potable water compatibility requirements to ensure safety and certification.

How does pvc compare to lldpe liners and polyethylene in terms of puncture resistance and abrasion?

PVC, LLDPE, and polyethylene each have their upsides. PVC is good for puncture and tear resistance, it has great flexibility and good abrasion resistance if proper formulation and reinforcement (textile-backed or non-reinforced as required) are done. LLDPE usually gives better resistance to some chemicals and stress cracking and thicker PE products can be even more puncture resistant in some installations. The choice of material depends on the specific site conditions, expected abrasion, and chemical exposure.