When the ground is difficult to work with due to construction, changes in land use, or heavy outdoor events, practicing good ground protection becomes a must. The solution to this is trackway mats—an ingenious idea that can provide very safe roadways and at the same time protect the ground below. The use of these thick and multi-functional mats will not only give a strong support on rough or fragile ground but also help to stop the destruction of nature. This piece of writing is about trackway mats, which are significant in different industries, considering the talk of their benefits and applications as well as the reason for their being the preferred choice in projects that have to do with both efficiency and environmental amenity. Keep reading in order to learn the ways trackway mats can be a turning point in your forthcoming project, as they would help you be practical and make a sustainable choice at the same time.

Introduction to Temporary Trackways

What are Temporary Trackways?

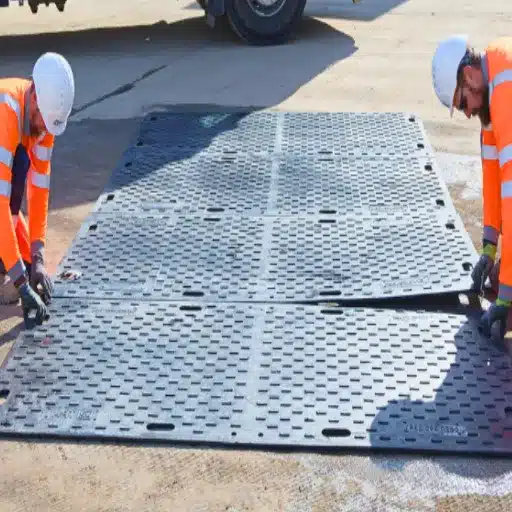

Temporary ways of working are portable modular systems that are meant to give an excellent and steady crossing over inaccessible and uneven lands. Generally, these systems are used in a wide range of applications such as road and bridge construction, and some conservation areas are only accessible through the use of temporary trackways. The materials used to make them include aluminum, high density polyethylene (HDPE), and composite materials, all of which are capable of withstanding the heaviest of loads and at the same time protecting the earth layer underneath.

The report which is based on the most recent statistics has indicated that the total temporary roads and access mats global market is going to be over 6% during the period of 2023 to 2030. Among the major reasons for this growth are infrastructure development, renewable energy projects, and green building. Moreover, temporary trackways are anticipated not only to improve efficiency but also to support sustainability goals by means of reducing soil compaction, preventing erosion, and saving plants.

Importance of Temporary Roads in Various Industries

Temporary roads have a crucial role in various industries by giving access, safety and productivity even in the most difficult places. For example, the building industry uses these systems in areas where the ground is wet or unstable, thus, the use of temporary roads reduces incidents and saves maintenance costs. The report by Global Construction Review of 2023, he stated that the application of temporary trackways could reduce the length of projects by up to 40%, which denotes a remarkable drop in time and cost.

In addition, the energy sector is largely dependent on the temporary roadways. They are an essential part of the logistics for moving heavy equipment and supplies to and from remote locations such as wind farms, gas and oil processing plants, etc. The International Energy Agency (IEA) insists that the rapid growth of the renewable energy sector has been the cause of a 15% yearly increase in the demand for modular road systems. These constructions not only facilitate the workflow but have also done so in an eco-friendly manner by reducing the soil compaction and thereby conserving the wildlife.

Applications of Temporary Trackways

Construction and Site Access

Temporary trackways are very important in the construction industry as they provide the site access that is safe and efficient. The mats are designed to give support even in the most challenging conditions, like muddy, sandy, or bumpy grounds, for the heavy machines, vehicles, and people. In fact, the latest industry data suggest that the use of temporary roadways can reduce site setup time by 50% at most. Consequently, the projects will no longer be delayed due to the rough ground conditions.

The modern trackway systems are designed in a way that they can withstand the loads of over 100 tons. In this way, the operations of heavy machines like cranes, excavators, and trucks will be safely carried out without the worry of ground collapsing. Moreover, the mats do not only protect the environment by lessening soil compaction that is harmful to plants but also preventing the latter which is of great importance in areas that might be ecologically sensitive. According to the market research firm Technavio, the global market for temporary roadways is expected to grow at a CAGR of 6% from 2023 to 2027, thus signifying the continuous demand for access solutions in construction projects.

Outdoor Events and Festivals

Temporary roadways are also one of the main factors that lead to the success of outdoor events and festivals. They provide stable paths for the transportation of equipment, the access of vehicles, and the movement of pedestrians, thus making festivals and events smooth-logistics operations. For instance, Glastonbury Festival in the UK and Coachella in the US, both of which are music festivals, attract hundreds of thousands of people, and the temporary roadways are the ones that enable the events to handle the crowds at such high-audience occasions efficiently.

A recent report forecasts that the worldwide revenue from music festivals alone will exceed $31 billion by 2026. This figure indicates a rise in the scale and impact of outdoor events. The appropriate infrastructure, like temporary trackways, became a must-have tool when it comes to leading the growing number of people attending these events. These systems are capable of handling large crowds and safeguarding natural landscapes from getting damaged. As a result, the environment will be preserved, and the event will be more pleasant.

Benefits of Using Trackway Mats

Cost-Effectiveness Compared to Permanent Solutions

The temporary road systems employed in the course of an event or a particular situation will be a lot cheaper if one uses trackway mats instead. The huge infrastructure cost was mostly attributed to the materials, labor, and maintenance. On the other hand, trackway mats remove these long-term expenses. Sometimes, the initial investment in trackway mats is less, and their characteristic of being reusable makes them an economically viable option for events or projects that happen repeatedly.

Recent figures indicate that the price of a permanent asphalt road installation is between $3 to $15 per square foot depending on the location and complexity of the project. In contrast, renting or purchasing trackway mats might cost a mere $1 to $4 per square foot, thereby making it a rather inexpensive option for short-term needs. Besides that, the use of recyclable materials for the production of trackway mats not only helps in cutting down end-of-life disposal costs but also provides an option that is both environmentally and economically friendly.

Environmental Impact and Sustainability

Trackway mats prove their worth in more ways than one besides their practicality in canceling environmental impact. The enormous environment disturbance reduction that results from trackway mats’ use is a major factor in natural habitat protection. Moreover, it reduces soil compaction where the Environmental Protection Agency (EPA) is involved. An EPA report published in 2023 indicated that soil compaction due to heavy machinery can cause extinction of certain plants and consequently, so there is a reduction in the plant population and an increase in erosion.

Furthermore, it is general practice for new resilient mats to be formed mostly from recovered polyethylenes which is the perfect way to embody the circular economy. The Association of Plastic Recyclers’ report reveals that recycling operations can be the reason behind a 30% decrease of greenhouse gases resulting from new plastic production as opposed to the use of fossil fuel-derived chemicals. This is why trackway mats can be categorized as very low carbon products that do not contribute to construction, oil and gas, and event management sectors, etc. Aside from being one of the green options, it is also the cheapest, thus making it the most resourceful and quickest way of upgrading the industries that are in need of the most power and hence attracting the biggest investments.

Innovations in Trackway Solutions

Latest Trends in Aluminum Trackway Technology

The technology of Aluminum trackway is continuously developing, and the main cause of this is the request of various industries for better products with longer life, eco-friendly, and versatile ones. Among them, the lighter and stronger alloy is the newest trend. The newly engineered aluminum composites are such that they can carry more weight without being heavy, and thus, the applications with heavy-duty requirements like construction sites, military, and events infrastructure, which need durability, can make use of them.

The innovation has gone up a strong notch with the use of modular design template installation. The modern-day solutions for aluminum trackway consist of panels that can easily be locked and are easy to assemble. The time for setting up has been reduced to 40% in comparison to the previous methods. The modularity provided by this option guarantees quick deployment in emergency cases and simultaneously ensures high reliability.

Moreover, sustainability has been a major factor that influenced the technology. With the introduction of recycling programs, aluminum trackways have been made less harmful to the environment and a few products even boast a recycling content of over 90%. In trying to portray a good picture of themselves and in complying with global carbon emission reduction programs, companies are now more willing to use these eco-friendly solutions in their project planning and execution.

Onwards and Upwards of Ground Protection Mats

Ground protection mats came into being with the help of the evolution of their eco-friendliness, strength, and versatility materials which were less demanding and therefore driving the field. These mats are the most effective tools in temporarily granting access to hard-to-reach or sensitive areas, providing safety ground measures as well as they are increasing safety and improving operational efficiency.

Ground protection mats made from High-Density Polyethylene (HDPE) are quite common to find these days. HDPE is a material that has a reputation for strength, flexibility, and chemical resistance. HDPE mats which are lighter than those made from wood or steel can also be easily moved and have a longer lifespan. Tests have revealed that depending on the specific model, HDPE mats can hold up to 120 tons making them suitable for the largest machines in construction, mining, and events areas.

Choosing the Right Trackway Mat

Factors to Consider for Site Access

Ground Conditions

The assessment of ground conditions on the site is a very crucial thing. Soft or bad ground, consisting of mud, sand, or swampy areas, will nearly always necessitate the use of heavy-duty mats made of composite or steel trackway mats to ensure stability and also to keep the equipment from becoming stuck. One study has found, for example, that using composite mats on unstable ground can reduce equipment downtime by up to 35%.

Load Capacity and Weight Distribution

The properties and the weight of the equipment that is being transferred or worked on at the site can have a major influence on the material selection. Heavy machinery usually requires the very thick mats that can support the load. The industry recommends the use of high-density polyethylene (HDPE) mats which can hold up to 120 tons, thus they are the preferred choice for heavy-duty applications.

Environmental Impact

Since protecting nature is a major concern, it becomes even more critical in delicate areas such as wetlands or forests. Biodegradable trackway mats made entirely from recycled materials are an excellent way to sustain the environment since they won’t cause any disturbance and at the same time provide reliable support. The latest trends indicate that there is a gradual shift of more than 40% of project managers in construction opting for the sustainable matting solutions.

Weather Considerations

The weather will definitely be one of the determining factors for mats. Extremely hot or cold weather, heavy rains, or snowfall could affect the performance of some materials. To illustrate, weatherproof rubber mats would be ideal for the projects that are going to be in severe weather conditions.

Comparing Different Materials: Aluminum vs. HDPE

Aluminum

Aluminum is a lightweight, strong, and recyclable material that has numerous applications in civil engineering and industry. Due to its high strength-to-weight ratio, it can support very heavy loads while still being easy enough to move around. Aluminum sheets or mats or platforms have very good anti-corrosive properties, especially when anodized, which extends their life outdoors. Moreover, aluminum is heat-resistant and can work well in extremely hot or cold conditions, so it is a good choice for sites with tough weather conditions.

On the other hand, the initial cost of aluminum is higher when us compared to other materials and may not be suitable for applications where cost is an important factor. However, if one considers its recyclability and long life, it usually offers better value in the long run. Industry statistics indicate that aluminum can last for about 20 years or even more with proper care, thus reducing the need for frequent replacements.

HDPE (High-Density Polyethylene)

HDPE is a versatile thermoplastic that is known for its high resistance to impacts, chemical stability, and being lightweight. Its low price is one of the reasons why it is widely used for temporary access mats, especially in construction or oil field applications. HDPE is water-repellant, UV radiation-proof, and chemical-resistant; hence, it can last for a long time even in tough environments. Another advantage is its pliability which allows it to easily adapt to the shape of the ground without cracking or breaking.

One of the major advantages of HDPE mats is that they can be manufactured from recycled plastic which is a move towards sustainability. Studies indicate that HDPE mats have a lifespan of approximately 7 to 10 years under normal conditions. However, HDPE may not be as good as aluminum in extreme temperatures, particularly at very high heat where thermal expansion might be an issue. Additionally, HDPE is durable but not as strong as aluminum, thus may not be able to hold extremely heavy loads.

Reference Sources

-

“On the Temporary Track of Construction Project”

- Key Findings: This research discusses the construction and evaluation of temporary tracks or rail lines, emphasizing their role in ensuring project continuity.

- Methodology: The study evaluates a temporary track at the Joglo Solo Intersection by calculating its structural and operational parameters.

- Read the paper

-

“Maintenance Study of Rail Track Structure for Temporary Track at Electrified Double Track Project (EDTP) Gemas-JB”

- Key Findings: This study reviews the maintenance and quality of temporary rail tracks used in the Electrified Double Track Project (EDTP). It highlights the importance of track geometry data in monitoring and maintaining track quality.

- Methodology: The research analyzes track geometry data and evaluates the quality of temporary tracks in the EDTP project.

- Read the paper

Frequently Asked Questions (FAQs)

How do heavy duty temporary panels cope with heavy loads and the requirements of a heavy-duty system?

Heavy-duty temporary panels are made to carry heavy loads that are measured in tonnes, making it possible for cranes, delivery trucks, and construction plants to operate on them. Heavy duty described systems or heavy use systems utilize reinforced materials and cross-serrated or textured surfaces which not only give traction but also evenly distribute footfall and wheel loads. Suppliers and experts will guide you through deciding panel thickness, bearing capacity and customizing the layout for safe working under actual site conditions.

When is the best time to arrange a site survey for planning temporary flooring and access solutions?

A site survey should be conducted right at the beginning of the planning process for temporary flooring or access solutions to evaluate the ground type, slopes, and drainage, and to spot any environmental constraints. The site survey will reveal the areas to be covered by temporary trackway, temporary ground protection, or walkway panels in order to create a safe access route, to protect sensitive areas, or to set up site compounds and marquee bases. A well-seasoned project supplier will match survey results with his formidable experience and will thus be able to point out the best product together with an installation plan.

Can temporary flooring be non-slip and provide traction for pedestrian use and walkways?

The answer is yes. Temporary flooring solutions very often include non-slip and anti-slip features. These features include serrated textures and specialized surfaces that minimize the risk of slipping in wet or muddy conditions. For pedestrian access and walkways, keeping the panels or mats that are suitable for footfall will ensure safe access for crew and visitors, and at the same time provide comfort and clear anti-slip solutions for high-traffic areas.

What is the performance of temporary trackway and ground protection systems in relation to uneven ground and slopes?

Ground protection systems are built to span and stabilize uneven ground thereby distributing the loads such that it does not lead to rutting and compaction. A lot of the temporary trackway options offer traction on slopes with their patterned surfaces and interlocking connections that are not easily dislocated under load. For steeper or softer slopes, suppliers with experienced staff will direct anchoring, ramping, and the use of extra supports to keep the temporary access safe and minimize risk to vehicles and workers.