In the case of difficult jobs in construction, crane operations, and heavy equipment projects, it is very important to have the right ground support. Heavy-duty composite mats are one of the new and eco-friendly ways to replace traditional wood or steel mats in the industry. These mats, however, still have the same properties as the old ones—they are very strong, durable, and reliable. But how do they work, and what exactly makes them the contractors’ and project managers’ preferred choice in challenging environments? This article takes the reader through the composite mat world, covering their pros, uses, and characteristics that distinguish them from others.

Introduction to Composite Crane Mats

Importance of Composite Mats in Modern Industries

Composite crane mats are now the essential elements of different modern industries because of their unmatched durability, adaptability and environmental benefits. Composite mats are made of high-quality materials and engineered precisely which are very different from traditional wooden mats which are made of low-quality materials. The most important materials used are high-density polyethylene (HDPE), and fiberglass as they help in giving the composite mats the strength and longevity which is a cut above the rest. They are made in such a way that they can easily bear the load of heavy equipment up to 600 psi which is the case in industries like oil and gas, construction, and renewable energy among others.

Lightweight and robust design is one of the best aspects of composite mats which brings down the transportation costs and makes the installation process very easy. To illustrate, research suggests that the weight of composite mats in comparison to that of traditional wooden mats could be as much as 40% less which would mean that moving the contractor has to use fewer resources. Moreover, their interlocking design provides stability even on uneven terrains which consequently leads to safer working conditions for both heavy machinery and site crews.

Heavy-Duty Composite Overview

Heavy-duty composite mats have different materials and configurations that correspond to the different needs of industries such as construction, oil and gas, and utility sectors. The main materials used are high-density polyethylene (HDPE), fiberglass-reinforced composites, and polyurethane which give these mats incredible strength, durability, and flexibility. Composites are not only durable but also resistant to moisture, UV radiation, and temperature changes, thus, ensuring a longer lifespan and lower maintenance costs, unlike the traditional wooden mats which succumb easily to such factors.

The most recent distribution data indicates that the market is slowly but surely shifting towards composite mats. As an illustration, HDPE mats are generally associated with more than 10 years of life; hence, they are cost-effective and eco-friendly options as compared to timber mats that are often replaced within 1-3 years. According to a report by MarketsandMarkets, the global composite mats market is expected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2028, primarily driven by the increasing emphasis on sustainable practices and the growing need from infrastructure projects and energy operations.

Benefits of Composite Mats Over Traditional Materials

Durability and Strength

Composite mats are the result of engineering aimed at being the best in the most demanding conditions, thus they are the most reliable option for the construction, oil & gas, and energy utilities industries. Besides, composite mats have done the traditional material like wood or metal impossible, with their undefeated durability and strength. They are made through great manufacturing processes and the use of high-performance polymers, which contribute to not only being resistant to but also non-warping, non-rotting, and non-corrosive.

New industry reports in the not-too-distant past say that the strength of composite mats is such that they can handle compressive loads of more than 600 psi (pounds per square inch), thereby making them ideal for the placement of heavy machinery and vehicles without the deformation or breakage risk. In addition, their life may last as long as 10-15 years based on the conditions of usage, which is way more than the life of wooden mats, which generally last 1-5 years under similar loads.

Weight and Transport Efficiency

Composite mats not only have the greatest durability but also possess the most exceptional performance in terms of weight design, which greatly increases their transport efficiency. The weight of composite mats is up to 50% less than that of steel or wooden mats. As an example, while a wooden mat can weigh 1,500 lbs., a similar composite mat has a weight close to only 750 lbs. Due to this weight disparity, fewer mats need to be loaded, leading to fewer trips that transport these mats and so, less fuel consumption and lower emissions from transportation.

Moreover, the less weight of composite mats means easier handling and installation on site. To deploy them, less manpower and machinery are required, which will result in faster setup times and reduced labor costs. The latest transportation logistics data suggests that the reduced weight can save up to 30% on transportation throughout the project, thus making composite mats not only economically viable but also environmentally friendly choices for operations of both small and large scales.**

Key Features of Heavy-Duty Composite Mats

Material Composition and Technology

Heavy-duty composite mats, as per their name, can take a beating and are still molded using cutting-edge engineering materials and top-notch manufacturing techniques to last for ages, be strong and adaptable. Usually, polyethane of very high density (HDPE) or similar thermoplastics composites that withstand blows, heat/cold and chemicals excellently are made with these mats. HDPE is the most popular choice because it is a combination of lightness and strength, hence the mats will be able to take very heavy equipment without breaking down, yet it will still be easy to move around and set up.

The findings state that HDPE composite mats can bear loads up to 600 psi which is the highest limit for the hardest of industrial and building applications. Besides, their eco-friendliness rises significantly because of the non-toxic and recyclable nature of its material composition compared to the environmental impact of traditional wood or steel.

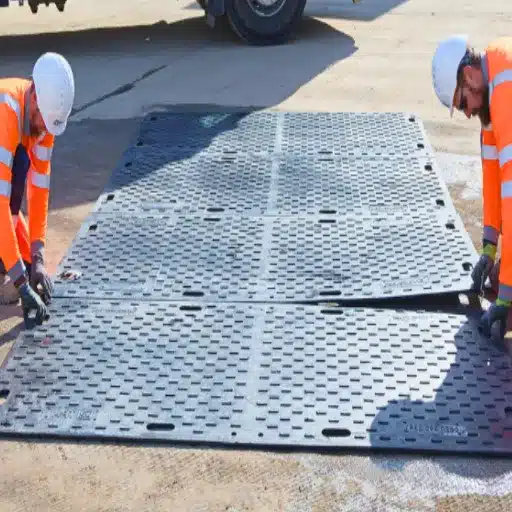

Interlock Systems for Stability

State-of-the-art interlocking systems have been incorporated into modern heavy-duty composite mats which come with remarkable stability and even load distribution. The interlocking systems are to attach individual mats tightly so that they remain together even when the pressure is very high and the conditions are quite difficult. The latest statistics state that interlocking systems can enhance mat stability by as much as 40%, hence the likelihood of shifting or separation at the time of operations is minimized.

The user-friendliness of such systems is a considerable feature. Most interlock patterns have user-friendly quick-connect systems or pin-and-hole methods that make integration smooth and thereby save time during setup. For example, installation of the new modular mat systems takes less than half the time that would be required for installation of traditional wooden or steel solutions. This efficiency goes hand in hand with lower labor costs and quicker project timelines.

Usage Scenarios for Composite Construction Mats

Applications in Challenging Environments

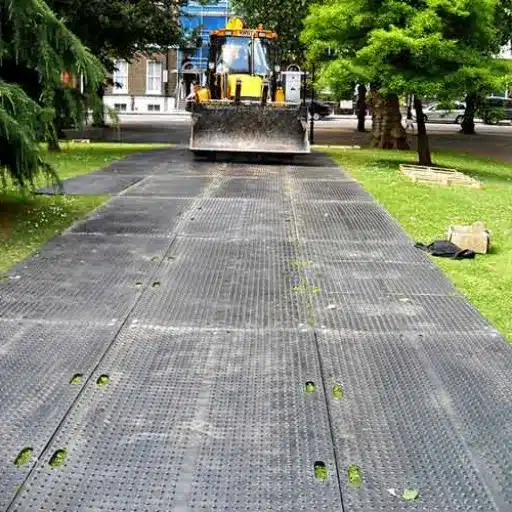

It has been essential for composite construction mats, in many environments, to use up their whole potential and prove their durability at the same time. Their advanced engineered design allows them to be very effective in the previously mentioned, among others, difficult areas while the traditional materials give up.

To illustrate, in swamps, composite mats present a stable, temporary road that lessens the impact on the environment by distributing the heavy loads uniformly so that there will be no soil displacement and damage to the sensitive ecosystems. Industry data shows that using composite mats can lower the ground pressure by as much as 70%, thus making it possible to continue the existence of indigenous habitats.

Examples of Projects Utilizing Composite Mats

- Pipeline Construction

The use of composite mats is quite common in the rat race of the oil and gas industry for pipeline projects. These mats give firm ground access, even in far-off and up-and-down terrains. As an instance, in the recent pipeline project in Texas, composite mats were implemented across a wetland area of considerable size to mitigate soil disturbance. Research has established that the deployment of composite mats in such projects slashes ground restoration costs by 40% when compared to the use of traditional wooden mats.

- Renewable Energy Projects

Composite mats are of tremendous assistance to renewable energy installations, consisting of wind farms and solar parks, etc. In a big wind energy project in the Middle West, mats were put in place to support the cranes and heavy equipment to move the turbines’ components over soft agricultural land. Reports show that the mats’ non-conductive properties and long life resulted in the cutting down of project delays and a 30% betterment of efficiency.

- Utilities and Power Transmission

Utility maintenance and power line installation are often done in the most challenging environments like wetlands, forests, and hilly areas. In a utility upgrade project in California, for instance, composite mats played the role of a reliable access-provider for the crews and the equipment during the rains without soil erosion occurring, thus, presenting a dilemma of sorts to the maintenance of the ecosystem. Data from manufacturer studies point out a 70% dip in the costs of environmental remediation due to the low ground pressure profile of the mats.

Maintenance Tips for Composite Access Mats

Cleaning and Care Practices for Composite Access Mats

Regular Cleaning

Over the years, composite mats can become dirty with debris like mud, oil, and chemicals. Using a pressure washer or industrial cleaning solutions will make sure that the residue on the surface is cleared off. In the opinion of the industry professionals, cleaning mats after every use not only reduces wear but also minimizes the damage that might be done to the surface.

Inspection for Damage

Regular checks for fissures, warping, and other types of damage are very important. A step ahead can lead to small troubles not being blown up to large ones that are hard to fix. Regular inspections are said to be able to double the longevity of composite mats by 20% in the average case. Customers who have used these mats for a long time have become convinced of the necessity of inspections and indicate a 15% increase in this annual practice across the industry.

Utilizing Proper Cleaning Agents

It is a must to use cleaning agents that are both effective and non-corrosive. The environment is not only being cleaned effectively but also being preserved with the use of biodegradable cleaners since they are the best choice. An increasing trend of 15% per annum is observed, indicating the transition towards the eco-friendly cleaning products in the industry has become well established.

Inspection and Repair Guidelines

It is paramount for the composite access mats to undergo regular inspection and prompt repair in order to maintain their durability and functionality. The checking process should be performed once before and once after each usage to spot any indicators, which could be cracks, deformities, or loose connections, of wear or damages. As per a research study done by Infrastructure Solutions, the mats that are subject to constant inspections have a 25% lower failure rate which, in turn, reduces project downtime and unexpected costs

In the case of small damages, the mats can be very often restored to a functional state by making use of quick repairs. For example, sealing tiny cracks with a polymer-based solution can help to not let moisture inside and hence prevent further deterioration. Besides, having a complete go on fasteners or connectors ensures the strength of the joined mat systems. In the case of extreme damage like big cracks or considerable warping, the process of changing the mats affected becomes crucial to eliminate the danger and inconveniences in operations.

Reference Sources

-

“H-Beam Type Crane Used ND Series Electric Wire Rope Hoist”

- This research discusses the production of fiber mats using composite materials, which can be relevant for crane mat applications in terms of material optimization and strength.

- Read the paper

-

“Decision support for hydraulic crane stabilization using combined loading and crane mat strength analysis”

- This paper provides a decision-support framework for hydraulic crane stabilization, analyzing the strength of crane mats under various loads using finite element analysis.

- Read the paper

Frequently Asked Questions (FAQs)

What exactly is a megadeck composite crane mat and when is it utilized?

Megadeck® composite crane mats are oversized, heavy-duty ground protection mats that are intended to form stable bases and working areas even on soft or marshy ground. They are very heavy mats that can spread out the weight of the loads and protect certain areas while allowing limited access, roads, and venues for cranes, transport vehicles, and heavy equipment. They are also a good solution for sites where wood mats would lead to comingling of different materials or in cases where environmental factors dictate the need for non-porous, easy-to-clean mats.

What is the role of composite mats in protecting the ground and stopping the spread of contaminants?

The use of composite ground protection mats helps to avoid contaminant and cross-contamination since they provide a surface that is non-absorptive and easy to clean and at the same time resists chemical spills and gas drilling residues. In contrast to wood mats which can hold back spills and thus eventually become a source of contamination, composite mats not only protect soil and groundwater in eco-sensitive regions but also facilitate easy clean-up of any spills.

Are composite crane mats produced from interlocking HDPE or other materials?

Composite crane mats are created with interlocking high-density polyethylene (interlocking HDPE) or fiber-reinforced polymer cores coupled with lasting surfaces; system7™ composite mats and dura-base® composite mats apply engineered composites that are highly durable but still light when compared to timber. The interlocking hdpe design options along with overlapping and interlocking system make for better traction, ease of assembly, and stability on uneven terrains.

Which composite mats are able to withstand the most extreme conditions with loads being applied repeatedly?

Dura-base® composite mats and megadeck® products are the tough one, amongst many others, for repeated heavy loads since they are built for heavy-duty service and superior weight distribution. Moreover, these mats usually do not get deformed and keep grip to the ground thus extending the period that they can be used even if cranes are kept on them continually.