The selection of correct garage flooring materials creates both aesthetic improvements and functional benefits. The flooring material you choose establishes the performance and maintenance requirements for your garage, which serves as your gym, work area, or vehicle storage space. Rubber flooring has become a preferred choice because it offers both durability and safety features and simple maintenance requirements. The article presents the top rubber flooring solutions for your garage area, which we will evaluate through their advantages to assist you in selecting the most appropriate option for your requirements. Your garage will undergo a transformation that creates a functional area that will endure through time.

The Importance of Choosing the Right Garage Floor

Durability and Safety of Garage Flooring

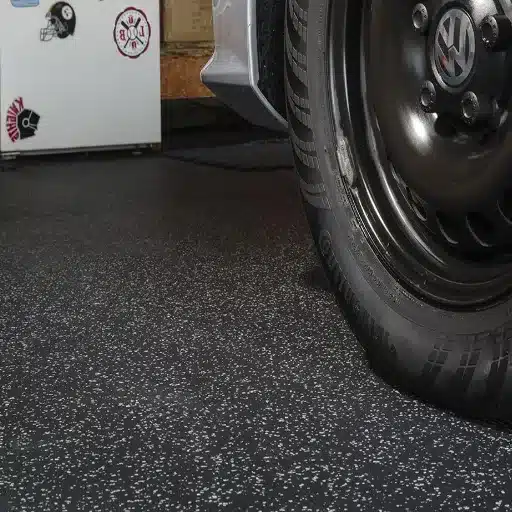

The exceptional durability and safety features make rubber flooring the perfect material for garage spaces because it can be used in various applications. The main advantage of this material exists because it can support the weight of vehicles, together with toolboxes and equipment. The rubber flooring system maintains its strength after handling 50,000 pounds per square inch pressure because of its design, which protects against cracking and degradation.

The safety benefits of rubber flooring come from its ability to deliver high traction performance even when surfaces become wet. Studies show that rubber surfaces that resist slipping can reduce accident risks by 40%, making them suitable for areas that experience spills and wet conditions.

Rubber flooring systems create sound-dampening effects, which make them essential for spaces that use loud equipment and machines. The proper installation of rubber flooring systems enables them to achieve sound absorption results, which decrease noise levels by 20%.

Rubber flooring maintenance requires minimal effort because it requires basic cleaning procedures. The non-porous surface of the material keeps oil, grease and all other chemicals that workers use in garages from creating permanent stains. Users can achieve complete surface cleanliness with damp mopping and basic sweeping, which helps them save time while working less.

Aesthetics of Garage Floors

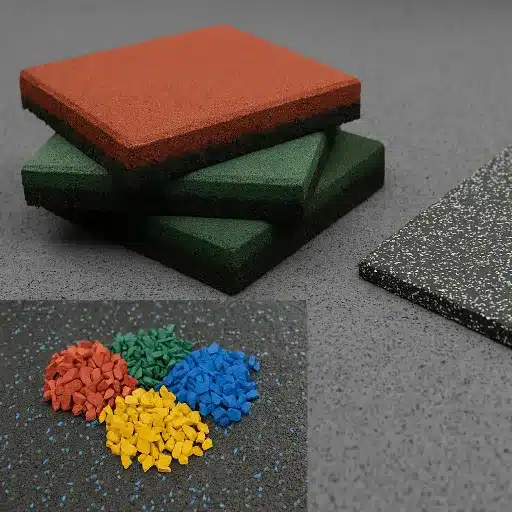

The current garage flooring solutions now provide various functionalities because their design combines functional components with long-lasting materials and attractive architectural design. Homeowners can choose from various rubber flooring solutions, which offer different color options, pattern choices and texture possibilities to achieve their preferred garage design that matches their personal style or their garage activities. Home designers use diamond plate patterns and coin designs to create industrial looks, while they use bold, colored, smooth tiles to create contemporary designs.

The popularity of epoxy coatings has grown because these materials create high-gloss finishes and special metallic effects. The 2023 market analysis showed that demand for epoxy garage flooring will rise because of its combination of visual appeal and impact resistance, which will result in a 61 annual growth rate. Current UV-resistant coatings provide advanced technology because they enable finishes to maintain their original vibrant appearance instead of turning yellow with time.

The rising demand for recycled rubber tiles occurs because consumers now seek environmentally friendly options to meet their flooring requirements. Sustainable flooring solutions not only upgrade garage aesthetics but also encourage environmentally friendly behavior. Homeowners can use all these available options to create visually appealing spaces that serve multiple functions in their garages.

Common Problems with Traditional Garage Floors

The typical method that builders use to build garage floors results in persistent problems that continue to occur throughout their entire operational period. The most common problem that emerges involves cracks, which develop when two particular conditions occur first through extreme temperature variations, and second, through the combination of weight loads and natural foundation settling. A recent study found that approximately 80% of homeowners experience surface cracks on their garage floors within their first five years after installation.

Concrete remains unprotected which leads to its decreased durability because its porous nature permits stain absorption from oils and chemicals and all types of automotive fluids. The material develops two distinct problems because invading substances lead to both material breakdown and visible marking. The report shows that 70% of garages contain visible oil stains, which decreases the time needed until the floor requires replacement.

The building faces its most significant challenge because it suffers from moisture-related building damage. The absence of required concrete floor seals enables water infiltration, which creates conditions that support mold and mildew development while producing dangerous, slippery surfaces. Construction experts found that garage floors that lack proper water drainage systems face a 30% increased structural damage risk over ten years.

The current products of epoxy coatings, polyaspartic coatings, and durable interlocking tiles serve as effective solutions to address operational challenges while they improve both the visual appeal and practical performance of garages.

Types of Garage Rubber Flooring

Rubber Garage Floor Tiles vs. Rolls

The high durability and slip resistance of rubber garage flooring make it popular among users who want flooring that requires minimal upkeep. The needs of a particular area determine which benefits of rubber floor tiles and rubber rolls will better suit the space.

- Rubber Garage Floor Tiles

Rubber floor tiles come in interlocking designs which allow users to install them without needing any special tools or adhesives. The product enables users to create their preferred layout because they can replace damaged tiles with new ones. Rubber tiles have shown they can withstand compressive strength up to 50,000 pounds, which makes them appropriate for supporting vehicles and heavy equipment. The floor design includes modular components that enable better airflow to pass through the space under the floor, which decreases the chances of moisture being trapped that would cause mold to develop. - Rubber Garage Floor Rolls

Rubber rolls create a smooth surface that does not have any joints or seams, which makes them simpler to maintain because dirt cannot build up in those areas. The product enables users to cover large spaces quickly, which makes it suitable for people who need to work in large garage spaces. The typical thickness of rolls ranges from 3mm to 12mm while users who need better cushioning and impact protection should choose the thicker versions. Some studies indicate that thick rubber rolls perform better at dampening sound and vibration, which is an important quality for garages that operate heavy machinery. The product offers users a cost-effective solution for large installations because its square foot price remains lower than that of tile products.

People need to evaluate their planned activities, the expected foot traffic and their financial resources before they choose between rubber tiles and rolls. The two available choices will keep their properties for an extended period, which ensures your garage floor will stay strong and attractive throughout the upcoming years.

Interlocking Garage Floor Tiles

The interlocking garage floor tiles became a popular flooring option because they allow for easy installation, and they maintain their durability while creating multiple design possibilities. The upcoming content presents complete advantages and supporting evidence for all elements of the matter at hand.

- Ease of Installation

The interlocking tiles have a snap-together system that allows users to install them without needing professional assistance or bonding materials. Research shows that homeowners can install 300 square feet of tiles within a few hours, according to current installation patterns. - Durability

The tiles consist of materials that include polypropylene and PVC that provide protection against chemical substances and oil spills and withstand strong impact forces. Research demonstrates that these materials can endure loads reaching 5,000 pounds, which makes them suitable for vehicle and heavy equipment usage. - Aesthetic Variety

Homeowners have access to multiple color options and textural choices, and design styles, which enable them to create their ideal garage design. Home improvement forums show that more than 60% of users from surveys choose checkerboard patterns and diamond textures because they find these designs to be modern. - Easy Maintenance

The tiles provide an uncomplicated method for maintenance and cleaning. The surface spills can be easily wiped away without creating permanent stains, and individual damaged tiles can be replaced while keeping the remaining floor intact. Consumer reviews show that replacement procedures need less than 10 minutes to complete because they require minimal effort to perform. - Cost-Effectiveness

The interlocking tiles have an initial cost range from $2 to $5 per square foot but they provide cost savings throughout their lifespan because they maintain their durability and need minimal upkeep. The cost of epoxy flooring installation can reach $12 per square foot, which requires multiple installations throughout its lifespan.

Homeowners prefer interlocking garage floor tiles because these tiles provide practical benefits and attractive design elements, which create a durable and functional space.

PVC Garage Flooring Options

Homeowners now have access to PVC garage flooring, which serves as the most adaptable and durable flooring choice among various outdoor residential flooring alternatives. The tiles are engineered to endure substantial weight while maintaining protection against chemical spills and delivering a slip-free surface which makes them suitable for both industrial use and residential garage environments. The worldwide PVC flooring market will experience a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030, according to recent industry data, because the product has become popular as an economical yet effective flooring option.

PVC tiles provide their users with a direct installation advantage because of their easy installation system. The products are built with interlocking systems, which eliminate the need for adhesive materials, resulting in both faster installation times and lower expenses. The weight capacity of PVC garage tiles enables them to support loads up to 20,000 pounds per tile, which makes them ideal for storing heavy vehicles and equipment. The research demonstrated that properly installed PVC flooring maintained its operational capacity for over 25 years with only essential maintenance, which proves its economic worth.

The tiles provide functional benefits but also allow homeowners to select from multiple color options, pattern designs, and texture varieties to create their ideal garage floor design. The newest models offer added functionality through their stain-resistant coatings and anti-fatigue features, which deliver better comfort for areas with frequent foot traffic. Modern garages provide advanced PVC garage flooring options, which enable garage owners to create both useful spaces and appealing design options.

Key Benefits of Rubber Flooring

Shock Absorption and Comfort

Rubber flooring delivers outstanding impact absorption capabilities, which enable its use in areas that require both strength and safe walking conditions. Recent studies demonstrate that rubber flooring material reduces impact force by 60 percent, which protects joints and muscles from injuries in high-impact locations like gyms and playgrounds. Children and athletes utilize this shock-absorbing feature, which prevents them from sustaining injuries that occur during falls or extended contact with solid surfaces. The soft surface of rubber flooring benefits people who require extended standing time in their workplaces and public spaces.

The development of new rubber flooring products offers enhanced ergonomic features, which the advancement of manufacturing technology has enabled. Anti-fatigue rubber mats have become common in both industrial and residential markets. The mats enable users to work for extended periods because they decrease foot fatigue by 50 percent, which boosts both productivity and user satisfaction. The shock-absorbing capabilities of rubber flooring make it the best choice for safety-focused projects because its shock-absorbing performance matches its long-lasting strength.

Moisture Resistance and Protection

Rubber flooring achieves excellent moisture resistance properties, which make it perfect for spaces that experience frequent water contact. Recent research shows that rubber flooring materials can block 99 percent of water penetration because their surfaces do not allow water to pass through. This feature prevents water damage while it decreases the risk of mold and mildew growth, which creates a more healthful home environment. The newest rubber flooring solutions use antimicrobial coatings to protect against both bacteria and allergens.

Rubber flooring provides superior durability and water resistance, which makes it the ideal flooring solution for basements, kitchens and gyms. Industry reports show that rubber flooring products maintain their structural strength for more than 20 years when exposed to high-moisture environments. The characteristics of rubber flooring make it a dependable, low-maintenance option that both commercial and residential spaces can use.

Ease of Installation and Maintenance

The combination of durable properties and simple installation and maintenance requirements makes rubber flooring a popular choice for various types of environments. The installation process becomes easier with modern interlocking tiles and roll-out mats, which need only basic tools for installation without requiring professional help. The rubber flooring market is expected to increase at a 5.3 percent compound annual growth rate between 2023 and 2030 because consumers demand both affordable products and sustainable options.

Most rubber floors require only a damp mop and mild detergent for cleaning, which makes them suitable for areas that experience high foot traffic and frequent spills. Antimicrobial coatings have become standard in rubber flooring products because they help maintain hygienic conditions in areas that experience heavy foot traffic, such as gyms and healthcare facilities. The market continues to expand because this product combines easy use with durable materials and hygienic properties.

Maintenance and Cleaning Best Practices

Routine Maintenance Tips

Industrial standards establish three essential maintenance methods that rubber flooring requires for its proper upkeep. The current industry standards require users to perform regular sweeping and vacuuming activities because it helps maintain surface cleanliness while preventing surface damage. The recommended method for deep cleaning requires users to apply a neutral pH cleaner, which needs water dilution because both harsh chemicals and acidic solutions cause material deterioration over time.

The study demonstrates that proper maintenance procedures result in improved performance outcomes for rubber flooring. A 2023 market report shows that high-quality rubber floors can last more than 20 years in residential spaces and 15 years in commercial areas with heavy foot traffic when regular cleaning and maintenance practices are followed. The manufacturing process uses antimicrobial treatments, which leading flooring brands report to achieve 99% bacterial reduction throughout their production process. The system enhances hygiene standards while it reduces the number of deep cleaning sessions that need to take place.

The organization needs to establish protective measures, which include protective mats at entryways, because they serve to collect both dirt and moisture. UV-stable coatings for sunlight-exposed areas serve two functions because they preserve color brightness while stopping color fading.

The combination of these practices with modern floor technology advancements allows owners to maintain both the functional performance and visual appeal of their rubber flooring throughout multiple years.

Cleaning Solutions for Rubber Floors

The main factor that determines how well rubber floors will maintain their original look and strength actually depends on both proper cleaning materials and proper cleaning methods. The latest research shows that neutral pH cleaners work best to remove dirt and grime because they clean effectively without damaging the rubber surface. The material will suffer permanent damage when exposed to acidic or highly alkaline cleaning products.

The business sector sees a rising trend towards buying automated floor cleaning machines for their commercial spaces. The study shows that scrubber machines equipped with soft-bristle brushes can cut down their cleaning times by 30% while also using less water during their operations. Multiple reports confirm that businesses can create environmentally sustainable operations through their regular use of biodegradable cleaning products, which also help them maintain their flooring.

For grease stains, you should first use a mild degreaser on the stained area before you start the rinsing process, which will help remove any remaining stain. The findings from professional cleaning services indicate that targeted location cleaning leads to an increase in overall floor lifespan, which ranges from 15% to 20%. The specific physical methods guarantee that rubber flooring will stay in its best condition and maintain its original purpose while surviving through its entire expected lifespan.

Long-Term Care for Your Garage Floor

The best practices that scientific studies and data studies provide for best practices should be followed to achieve both durability and aesthetic quality for your garage floor. The industry experts recommend that garage floor owners apply appropriate epoxy or polyurethane coatings to their surfaces because these coatings will enhance their protection against chemical stains and abrasions by 50%. The protective layer provides surface strength together with easy cleaning capabilities, which prevent oils and salts from entering porous material.

The experts recommend that establishments establish cleaning procedures that need to be done at regular intervals. The research indicates that garages located in high-traffic areas that experience extreme weather conditions require monthly cleaning to eliminate the built-up dirt. The combination of a garage mat with rubberized flooring material will increase the flooring material’s lifespan because it protects against floor damage while collecting dirt before it touches the floor surface.

Proper garage ventilation serves as an essential need for areas that experience high-humidity situations. The accumulation of moisture leads to mold and mildew growth, which results in permanent damage to the floor. The use of dehumidifiers or fans helps to decrease indoor humidity levels, which results in better garage floor protection and improves the floor’s condition throughout its useful life.

Reference Sources

-

Garage Flooring Market Size and YoY Growth Rate, 2025

This report provides insights into the garage flooring market, including growth rates and market size, which can help assess the demand and feasibility of rubber flooring.

Read the report here -

Garage Flooring Market Analysis 2026

This analysis highlights the global garage flooring market trends, including projections for market growth and consumer preferences.

Explore the analysis here -

Garage Floor Mat Market Research Report 2033

This market research report focuses on garage floor mats, including rubber options, and provides data on market size and future forecasts.

Access the report here

Frequently Asked Questions (FAQs)

What is garage rubber flooring, and why is it a good option for my garage space?

Garage rubber flooring gives people a strong yet flexible floor system which needs rubber material to handle both high-impact work and heavy load pressure. The product delivers exceptional protection against damage while providing a secure, non-slip surface and convenient cleaning solutions. The material protects your garage floor and stored items through its ability to absorb shocks.

What are the best types of rubber flooring for garages?

The most popular options for garage rubber flooring include rubber mats, interlocking rubber tiles, and rubber rolls. Rubber mats provide a solution for specific areas that require quick installation but interlocking tiles allow users to create their own unique design. The use of rubber rolls enables users to create seamless floor systems that extend across large areas. The different products provide moisture protection and long-lasting durability, which fulfill multiple requirements.

Can rubber flooring handle heavy equipment and vehicles?

Rubber flooring provides essential protection against damage that results from both heavy machinery operations and automotive traffic. The material handles heavyweight conditions without developing cracks or tears, which makes it suitable for homeowners who use their garages to store vehicles and equipment.

What methods do you use to clean and maintain rubber flooring?

The surface of rubber flooring requires only basic cleaning methods for its maintenance needs. The surface stays clean because regular sweeping or vacuuming removes all dust and dirt particles while users clean the floor with mild detergent and water. The material provides both stain protection and moisture protection which makes it appropriate for garages that experience frequent spills.

Does rubber flooring protect against moisture and temperature fluctuations?

Rubber flooring withstands both moisture and humidity and temperature variations, which allows it to function in all climatic conditions for garage use. The material’s non-porous surface prevents water from entering, which reduces the risk of mold and mildew growth. The system keeps its flexible characteristics and maintains its original shape through all temperature changes which ensures its extended product life.

Does rubber flooring present environmental risks and safety hazards?

A large portion of rubber flooring materials consists of recycled content which includes used tires making these products environmentally friendly. Choosing recycled or sustainable rubber flooring helps you decrease environmental waste while obtaining a durable and high-performing garage surface.