The apt foundation is key to building a driveway that is durable, stable, and environmentally friendly. Traditionally, paving has always […]

As a premier provider of high-quality geotextiles for diverse civil engineering applications, our products are engineered to meet stringent international standards, ensuring superior performance in filtration, separation, reinforcement, protection, and drainage projects. With a focus on innovation and reliability, our geotextile range offers robust and cost-effective solutions for infrastructure development, environmental protection, and construction challenges.

Geotextile fabric is a permeable textile material made from synthetic fibers, used primarily in civil engineering and construction projects. These fabrics are placed in contact with soil to perform separation, filtration, reinforcement, protection, or drainage functions. By stabilizing soil and controlling water flow, geotextiles improve the performance, lifespan, and cost-effectiveness of infrastructure. They are crucial in applications ranging from road construction and drainage systems to erosion control and landfill liners.

Determine Primary Function: Identify the main purpose of the geotextile, whether it's separation, filtration, reinforcement, drainage, or protection, as different types excel in specific roles.

Analyze Site Conditions: Assess the soil type, particle size distribution, and anticipated hydraulic conditions to select a fabric with appropriate filtration and permeability characteristics to prevent clogging and ensure water flow.

Evaluate Mechanical Requirements: Consider the expected loads, required tensile strength, puncture resistance, and elongation properties based on the application (e.g., road construction vs. drainage trench) to ensure the fabric can withstand stresses.

Review Durability Needs: Account for long-term exposure to UV light, chemicals in the soil, and potential biological activity at the site when choosing the material composition and lifespan specifications.

Match Fabric Type to Application: Select between woven, nonwoven, or specialty geotextiles based on the performance characteristics required for the specific civil engineering task and expected environmental challenges.

Geotextile fabric provides essential benefits in civil engineering, including enhancing soil stability, controlling water flow, and improving project longevity. They are easy to install, resistant to environmental degradation, and offer cost-effective solutions for challenging ground conditions.

Improves the load-bearing capacity and structural integrity of soil layers, reducing settlement and increasing project lifespan.

Resists biological and chemical degradation, as well as UV exposure, ensuring reliable performance over many years.

Prevents the mixing of soil particles while allowing water drainage, crucial for maintaining the efficiency of drainage systems.

Reduces the need for costly aggregate materials and minimizes maintenance requirements for infrastructure projects.

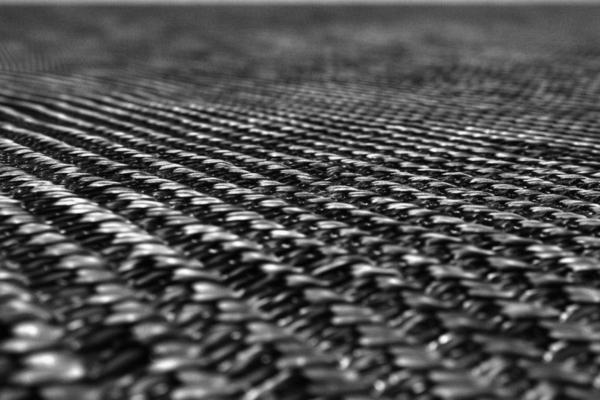

These fabrics are produced by weaving monofilament or multifilament yarns into a stable textile structure. Known for their high tensile strength and low elongation, they are primarily used for reinforcement, separation, and stabilization applications where strong support and load distribution are critical.

Manufactured by bonding fibers together randomly using needle punching, heat bonding, or chemical bonding. Their random structure provides excellent permeability and filtration properties. They are commonly used for filtration, drainage, separation, and protection layers in various civil engineering projects.

Formed by interlocking a series of loops of yarn. While less common than woven or nonwoven, knitted geotextiles can offer specific properties like high elongation and flexibility. They are sometimes used for reinforcement or drainage applications.

| Customization Parameter | Woven Geotextile Specifications | Non-Woven Geotextile Specifications | Knitted Geotextile Specifications | Notes |

|---|---|---|---|---|

| Product Type | Reinforcement mats, separation fabrics, road stabilizers. | Filter fabrics, drainage layers, erosion control sheets. | Interlocked reinforcement grids, decorative meshes. | Can be tailored based on project needs or design preferences. |

| Size / Dimensions | Customizable from 1m to 6m wide, lengths up to 100m. | Customizable from 2m to 5m wide, lengths up to 50m. | Customizable from 1.5m to 4m wide, lengths up to 75m. | Range depends on application type and structural requirements. |

| Material Thickness | e.g., 0.2mm, 0.3mm, 0.5mm options available. | e.g., 0.4mm, 0.6mm, 0.8mm options available. | e.g., 0.3mm, 0.45mm, 0.7mm options available. | Selected based on intended use and durability needs. |

| Material Color | Available in neutral tones or custom green shades. | Available in black or white with optional gray hues. | Available in blue or custom earth tones. | Color effects like opaque or translucent achievable. |

| Printing Process | Heat stamping or basic pattern imprinting. | No printing, focus on texture variation. | Embossed designs or subtle logo etching. | Chosen based on design complexity and project scale. |

| Accessory Options | Anchoring clips, edge binding, UV-resistant coatings. | Drainage tubes, soil stabilizers, protective overlays. | Tension cables, interlocking fasteners, reflective strips. | Configured according to specific application demands. |

| Minimum Order Quantity (MOQ) | Varies by complexity, contact for details. | Varies by size, contact for details. | Varies by design, contact for details. | Supports small batches and large-scale production runs. |

Superior Performance: Our fabrics are engineered for optimal functionality in filtration, separation, reinforcement, and drainage, ensuring project success and longevity in diverse conditions.

Reliable Quality: Manufactured under strict quality control standards, our geotextiles offer consistent properties and durability that meet or exceed international specifications for critical applications.

Comprehensive Range: We provide a wide variety of woven and nonwoven geotextile types, offering tailored solutions and configurations to precisely match the specific demands of your project needs.

Expert Support: Benefit from our technical expertise and guidance in selecting the most suitable geotextile product and implementing best practices for installation to maximize effectiveness.

Proven Durability: Our fabrics are designed to withstand harsh environmental factors, including chemical exposure and UV degradation, providing reliable, long-term performance in demanding civil works.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

Geotextile fabric serves multiple critical functions in civil engineering. Its primary uses include separating distinct soil layers to prevent mixing, filtering water while retaining soil particles, facilitating drainage of excess moisture, reinforcing soil to increase stability and bearing capacity, and protecting other materials like geomembranes from damage. These applications improve the performance and longevity of infrastructure projects.

Yes, geotextile fabric is designed to be permeable, allowing water to pass through it. This characteristic is fundamental to its use in filtration and drainage applications. While preventing the movement of soil particles, the fabric’s structure permits the free flow of water, which is essential for managing groundwater, preventing hydrostatic pressure buildup, and maintaining dry conditions where needed in construction.

Geotextile fabric is typically placed in various locations within civil engineering and environmental structures. It is commonly installed beneath roads, railways, and embankments for separation and reinforcement. It is also used around drainage pipes and trenches for filtration and drainage, on slopes for erosion control, within retaining walls for reinforcement, and as a protective layer in landfills and reservoirs.

The lifespan of geotextile fabric varies depending on the material type, manufacturing quality, site conditions, and exposure to environmental factors. High-quality synthetic geotextiles made from materials like polypropylene or polyester are designed for long-term performance, often lasting 50 to 100 years or more when properly installed underground and protected from UV light and harsh chemicals.

Geotextile fabric can be held down using several methods, depending on the application and ground conditions. Common techniques include using metal staples, pins, or U-shaped fasteners to secure the fabric to the ground. Placing fill material (like soil, aggregate, or rock) on top is the most typical method for permanent hold-down. Edges can also be trenched and buried for stability.

The required overlap for geotextile fabric panels depends on the application, the strength of the fabric, and whether the fabric is subjected to tension or differential settlement. Standard recommendations often range from 300mm to 600mm (12 to 24 inches). Higher overlaps may be required in critical load-bearing applications or areas prone to significant movement to ensure continuity and prevent gaps.

Generally, yes, landscape fabric is designed to be permeable to allow water and nutrients to reach the soil and plant roots beneath, while suppressing weed growth. However, the permeability can vary significantly depending on the fabric type and quality. Geotextile fabrics used in civil engineering are specifically engineered for controlled permeability for filtration and drainage functions.

In many landscape applications, soil, mulch, or aggregate is placed directly on top of the landscape fabric. This serves to hold the fabric in place, protect it from UV degradation, and provide a medium for planting or surface finish. In civil engineering uses, geotextiles are typically covered with soil, aggregate, or other construction materials as part of the layered structure they are reinforcing or separating.

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

The apt foundation is key to building a driveway that is durable, stable, and environmentally friendly. Traditionally, paving has always […]

Retaining walls, in today’s construction, are balancing the issues of structural integrity versus aesthetic appeal and conflicting terrains. Among the […]

Concrete Canvas is currently changing the ways of construction and infrastructure projects. The material fuses the hard-wearing nature of concrete […]

The use of heavy equipment in construction, landscaping, and renovation projects is often impossible to avoid, but it also tends […]

PVC geomembrane liners have the best overall performance in durability and reliability, which is why they are highly regarded by […]

Geomembrane liners are used in different industries but their major role is to prevent leakage as a barrier for which […]

Geomembrane sheets have brought about a significant change in the way civil engineers consider and plan opposite critical infrastructure projects, […]

In general, choices of materials for construction, landscaping, and environmental engineering made nowadays could be a total turn-around. The non-woven […]

Choose our premium geotextile fabrics for your next civil engineering project. Engineered for exceptional performance in filtration, separation, reinforcement, and drainage, our solutions ensure durability and efficiency for roads, drainage systems, erosion control, and more. Enhance your project’s success and longevity with materials you can trust. Discover the difference quality geotextiles make.

A: Geotextile fabric is a permeable synthetic textile used in various civil engineering applications. Its primary functions include separation of dissimilar materials, filtration to allow water flow while retaining soil, drainage of excess water, reinforcement of soil structures, and protection of geomembranes from puncture.

A: A non woven geotextile is highly valued for its excellent filtration and drainage capabilities due to its random fiber structure and high permeability. It is also more flexible and conformable than woven types, making it suitable for applications requiring good soil retention and cushioning properties, such as around drainage pipes or beneath riprap.

A: The main difference lies in their manufacturing process and structure. Woven geotextiles are made by weaving individual threads or tapes, resulting in high tensile strength and low elongation, ideal for reinforcement. Non woven geotextiles are manufactured by bonding fibers randomly, giving them higher permeability and puncture resistance, making them better for filtration and separation.

A: Geotextile drainage fabric, often nonwoven, is installed around perforated pipes or within drainage layers. It acts as a filter, preventing surrounding soil from entering and clogging the drainage system while allowing water to freely pass into the drain, thus improving the efficiency and lifespan of subsurface drainage structures and reducing hydrostatic pressure.

A: Using geotextile fabric for driveway construction is highly recommended. It provides separation between the subgrade soil and the aggregate base layer, preventing the aggregate from sinking into the soft subgrade and maintaining the strength of the base. This separation function enhances the load-bearing capacity and extends the lifespan of the driveway surface.

A: Selecting the appropriate filtration geotextile is crucial to ensure effective water management without clogging. The fabric’s apparent opening size (AOS) must be suitable to retain the specific soil particles while allowing water flow. An incorrect choice can lead to either excessive soil migration or premature clogging, undermining the drainage or filtration system.

A: No, geotextile fabric itself is permeable and is not designed for waterproofing. Waterproofing requires an impermeable barrier, such as a geomembrane. Geotextiles are sometimes used in conjunction with waterproofing membranes as a protection layer (cushioning the membrane) or as a drainage layer (removing water away from the membrane), but they do not provide the waterproof barrier themselves.

A: Common properties of geo textile material include mass per unit area, tensile strength, elongation, puncture resistance (like CBR strength), tear strength, permittivity (for water flow perpendicular to the fabric), and transmissivity (for water flow within the plane of the fabric). Resistance to UV, chemicals, and biological degradation is also important for long-term performance.

A: Geotextile landscape fabric, often used for weed suppression or light separation in gardens, typically has lower strength, durability, and permeability specifications compared to industrial-grade geotextiles used in civil engineering. Landscape fabric may be less resistant to UV and environmental factors than geotextiles designed for critical, long-term infrastructure applications.