Gardening enthusiasts know the struggle all too well—unwanted roots creeping into garden beds, competing with prized plants for nutrients and […]

Weve spent years perfecting geomembranes that hold up under the toughest civil-engineering demands. Customers find the high impermeability, long-lasting durability, and burn-resistance they expect from products meeting strict global norms. Sustained design work keeps prices sensible while delivering dependable barriers for landfill ponds, industrial lining, and storm-water control.

A geomembrane is an impermeable synthetic membrane, often made from materials like HDPE geomembrane, PVC geomembrane, or other polymers, used primarily in civil engineering and environmental projects. As a geomembrane liner or geomembrane pond liner, it provides containment, prevents leakage, and ensures environmental protection. By controlling fluid migration, geomembranes enhance the durability, safety, and cost-effectiveness of applications like landfills, ponds, and water management systems.

Material Type: Select geomembrane sheet materials like HDPE, LLDPE geomembrane, or PVC based on chemical resistance and flexibility needs. LLDPE geomembrane offers greater flexibility for uneven surfaces.

Project Requirements: Assess containment needs; impermeable geotextile may complement geomembranes for added filtration in landfill or pond liners.

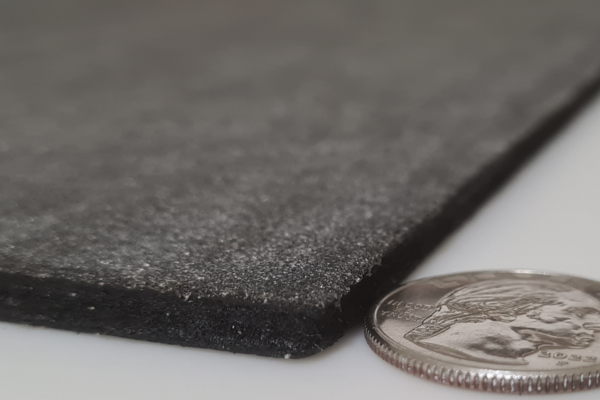

Thickness: Choose geomembrane thickness (0.5mm–3mm) based on durability and puncture resistance required for the application.

Environmental Conditions: Ensure the geomembrane withstands UV exposure, temperature extremes, and chemical interactions in the project environment.

Installation and Cost: Evaluate ease of installation and budget; LLDPE geomembrane often balances cost-effectiveness with performance for diverse applications.

Geomembrane liners deliver critical benefits in civil engineering, including preventing leakage, ensuring environmental protection, and enhancing project durability. They are easy to install, resistant to chemical and UV degradation, and provide cost-effective solutions for containment and water management in challenging conditions.

Improves fluid barrier capacity, preventing leaks and extending project lifespan.

Resists chemical and UV degradation, ensuring reliable performance over years.

Prevents soil and water mixing, maintaining efficiency of containment systems.

Reduces need for costly materials and minimizes maintenance for infrastructure projects.

High-Density Polyethylene Geomembranes are produced from durable HDPE resin, offering exceptional chemical resistance and tensile strength. Widely used for landfill liners, ponds, and containment where impermeability is critical.

Linear Low-Density Polyethylene Geomembranes are manufactured with flexible LLDPE, providing excellent elongation and puncture resistance. Commonly used in mining, wastewater treatment, and flexible containment applications.

Ethylene Propylene Diene Monomer Geomembranes are made from synthetic rubber, offering superior elasticity and weather resistance. Frequently used in roofing, reservoirs, and decorative ponds for long-term waterproofing.

Bituminous Geomembranes are produced by combining bitumen with reinforcement layers, providing robust waterproofing and durability. Commonly applied in tunnels, foundations, and underground structures for moisture protection.

Polyvinyl Chloride Geomembranes are crafted from synthetic PVC with plasticizers, offering excellent flexibility and UV resistance. Frequently used in ponds, canals, and landfill liners for durable waterproofing.

Geosynthetic Clay Liners are manufactured by sandwiching bentonite clay between geotextiles, offering natural sealing properties. Widely used in landfill caps, canals, and environmental containment for low permeability.

| Customization Parameter | HDPE Geomembrane Specifications | LLDPE Geomembrane Specifications | PVC Geomembrane Specifications | Notes |

|---|---|---|---|---|

| Product Type | Impermeable liners, containment | Flexible containment liners | Waterproof liners, pond liners | Can be tailored based on project needs or design preferences. |

| Size / Dimensions | Customizable from 2m to 8m wide, lengths up to 100m | Customizable from 2m to 6m wide, lengths up to 50m | Customizable from 1.5m to 5m wide, lengths up to 75m | Range depends on application type and structural requirements. |

| Material Thickness | e.g., 0.5mm, 1.0mm, 2.0mm options available | e.g., 0.4mm, 0.8mm, 1.5mm options available | e.g., 0.3mm, 0.6mm, 1.2mm options available | Selected based on intended use and durability needs. |

| Material Color | Available in black or white with optional gray hues | Available in black with optional green shades | Available in blue or custom earth tones | Colors like opaque or translucent achievable. |

| Printing Process | Heat stamping or basic pattern imprinting | No printing, focus on texture variation | Embossed designs or subtle logo etching | Chosen based on design complexity and project scale. |

| Accessory Options | Anchoring clips, edge binding, UV-resistant coatings | Drainage tubes, stabilizers, protective overlays | Tension cables, interlocking fasteners, reflective strips | Configured according to specific application demands. |

| Minimum Order Quantity (MOQ) | Varies by complexity, contact for details | Varies by size, contact for details | Varies by design, contact for details | Supports small batches and large-scale production runs. |

Superior Performance: Our Geomembranes are engineered for optimal functionality in containment, waterproofing, and protection, ensuring project success and longevity in diverse conditions.

Reliable Quality: Manufactured under strict quality control standards, our Geomembranes offer consistent properties and durability that meet or exceed international specifications for critical applications.

Comprehensive Range: We provide a wide variety of Geomembrane types, offering tailored solutions and configurations to precisely match the specific demands of your project needs.

Expert Support: Benefit from our technical expertise and guidance in selecting the most suitable Geomembrane product and implementing best practices for installation to maximize effectiveness.

Proven Durability: Our Geomembranes are designed to withstand harsh environmental factors, including chemical exposure and UV degradation, providing reliable, long-term performance in demanding civil works.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

A geomembrane is used as an impermeable barrier in civil engineering for containment, including landfill liners, pond sealing, and wastewater treatment, preventing leakage and protecting the environment.

HDPE (High-Density Polyethylene) geomembrane is the most chemically resistant, enduring exposure to acids, alkalis, and solvents, making it ideal for industrial and mining applications.

No, geomembranes are designed to be impermeable, blocking water and gas movement, ensuring effective containment in projects like reservoirs and landfills.

Geomembranes are used in landfills, mining heaps, water storage (ponds, canals), tunnels, and agricultural applications, providing waterproofing and environmental protection.

Geomembrane liners typically range from 0.5 mm to 2.5 mm thick, with thickness varying based on project needs, such as 1.0 mm for ponds or 2.0 mm for heavy-duty landfills.

Yes, geomembranes are waterproof, offering a reliable barrier against water penetration, essential for applications like irrigation systems and flood control.

XR-5 geomembrane is a reinforced PVC (Polyvinyl Chloride) material, known for flexibility, UV resistance, and strength, commonly used in floating covers and secondary containment.

Raw materials include polyethylene (HDPE, LLDPE), PVC, EPDM rubber, and polypropylene, combined with additives for UV and chemical resistance during manufacturing.

A geomembrane liner is used to line landfills, ponds, and canals, preventing seepage, protecting groundwater, and ensuring containment of liquids or waste.

Install geomembrane by preparing a smooth surface, unrolling the material, overlapping seams, welding or sealing joints, and anchoring edges with soil or weights to ensure a secure, watertight layer.

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

Gardening enthusiasts know the struggle all too well—unwanted roots creeping into garden beds, competing with prized plants for nutrients and […]

When it comes to construction, landscaping, or erosion control projects, geotextile fabric serves as a fundamental material for enhancing stability, […]

When it comes to maintaining a pristine and thriving garden, dealing with relentless weeds can feel like a never-ending battle. […]

When it comes to modern construction, environmental engineering, and infrastructure development, understanding the right materials for the job is crucial. […]

When it comes to selecting the ideal geomembrane liner for a specific project, two of the most commonly compared options […]

When it comes to safeguarding our environment and managing vital water resources, geomembranes play a pivotal role behind the scenes. […]

When it comes to building and maintaining a pond, choosing the right liner is a critical decision that can significantly […]

The use of heavy equipment in construction, landscaping, and renovation projects is often impossible to avoid, but it also tends […]

Choose our premium geomembranes for your next civil engineering project. Engineered for outstanding performance in containment, waterproofing, and protection, our solutions ensure durability and efficiency for landfills, ponds, mining, and more. Enhance your project’s success and longevity with materials you can trust. Discover the difference quality geomembranes make.

A: In 2025, geomembrane manufacturers are introducing advanced UV-resistant coatings and recyclable composite geomembranes, enhancing sustainability and performance for modern civil projects.

A: Geomembrane manufacturers implement strict quality controls and use eco-friendly materials like HDPE and LLDPE, adhering to international standards to ensure environmental compliance in projects like landfills and mining.

A:

A composite geomembrane combines geotextiles with a geomembrane layer, offering enhanced tensile strength and impermeability for applications like landfills and mining.

A:

Geomembrane manufacturers use strict quality control, advanced production lines, and certifications like ISO 9001 to ensure durable, reliable products.

A:

Composite geomembranes are commonly applied in landfills, aquaculture ponds, and road construction for their dual benefits of strength and waterproofing.

A:Geomembrane manufacturers use HDPE, LLDPE, PVC, and polypropylene, often with additives for UV and chemical resistance.

A: A composite geomembrane is manufactured by heat-bonding geotextiles to geomembranes using calendaring or hot-melt technology for integrated performance.

A:Geomembrane manufacturers provide customized, high-volume solutions with technical support, ensuring cost-effective and durable outcomes for large-scale projects.

A:Composite geomembrane in mining offers leak resistance, soil stabilization, and chemical protection, enhancing safety and environmental containment.