Few methods can compete with articulated concrete block (ACB) mats in strength, adaptability, and cost efficiency for erosion control and shoreline stabilization. These versatile systems serve as a common choice for engineers and environmental professionals who seek reliable means of combating water flows and soil erosion under difficult conditions. This article will give perspective on how ACB mats function, their main advantages, and why they have come to take hold in modern undertakings. No matter if you undertake a large-scale construction job or merely want to protect susceptible landscapes, this primer will aid in understanding why ACB mats have emerged as a truly revolutionary solution in sustainable and long-term erosion control.

Introduction to Articulated Concrete Block Mats

An articulated concrete block or ACB mat is a system constructed by contoured concrete blocks for erosion control against soil erosion or aggradation by water flow; its constitutive elements are highly flexible in nature, durable, and remain practically the most effective means of slope, shoreline, or channels stabilization and erosion-prone structures. They are designed to withstand very high velocity of water, besides their ability to adjust themselves to site conditions, therefore making them highly suitable for temporary and permanent solution to the erosion control projects.

What Are Articulated Concrete Block Mats?

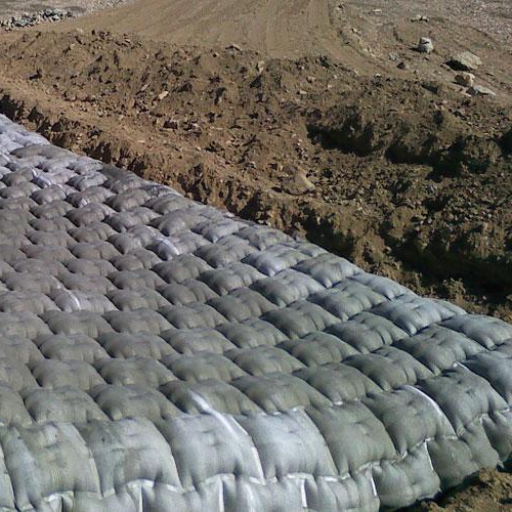

Articulated Concrete Blocks (ACBs) are innovative systems that serve the dual purpose of erosion control and soil stabilization for areas exposed to heavy water flow and erosion. This mat consists of concrete blocks joined with cables or the like from jointing mechanisms. These are thereby allowed to flex and conform to the terrain profile. The ACB systems have gained in popularity due to their durability and being adaptable to a wide variety of sites such as river banks, spillways, storm water channels, levees, and shorelines.

In engineering terms, the ACBs stand against water velocities of up to 20-25 feet per second for un-grouted applications, while much higher velocities are sustained if grouted. Research indicates that ACBs will reduce the requirement of repair works on a yearly basis for high-risk terrain, partly representing cost saving in the longer term. These are the systems that go in very well with the environment. The open-cell type of majority of ACB mats allow for good growth of vegetation, which aids in integrating the system with the environment, and the vegetation lays down a further layer of erosion control through its root system.

Recent engineering reports indicate that ACBs are a very versatile technique, allowing the project team to select the shape and size suited to the job. For example, they may be combined with geotextile fabrics for added filtration and stability or integrated with other erosion control measures into a layered solution. Also, a large number of modern ACB mats incorporate eco-friendly properties highlighting the use of recycled materials, thus further promoting sustainability.

ACB mats can provide functional utility as well as aesthetic properties, all while continuing to protect erosion control effectively. Given its proven efficiency in controlling flood risk and minimizing environmental degradation, it is regarded as a tool for engineers and environmental planners alike.

Importance of Articulated Concrete Solutions

Articulated concrete blocks (ACB) are much appreciated worldwide for the greatest measures in preventing soil erosion and fighting catastrophic climatic events. Recent data tend to show that more and more are being set up in flood-prone areas. According to a study report, if placed correctly, ACB systems can reduce surface erosion by up to 90%, being a good motivation to lower maintenance costs in further steps. Also, studies have shown these systems can sustain water velocities of up to 25 feet per second, ensuring that they provide reliable protection from high-intensity floods.

ACBs are generally preferred for their ability to integrate into the natural environment. For example, vegetation can be introduced into the system design to maintain structural integrity while enhancing biodiversity. The manufacturing processes have increasingly been carried out in an environmentally sound fashion with recycled aggregates being introduced into ACBs to curb carbon emissions by about 15-20% in comparison with the standard concrete method. These developments promote ACBs as an appropriate solution towards a sustainable infrastructure, that benefits both environment and community resilience.

Overview of Applications

These are truly unique systems capable of providing a variety of solutions, especially to infrastructure and environmental projects. One of the major applications to ACBs is erosion control where shoreline, riverbank, and slope stabilization are initiated. According to more recent information, the U.S. Army Corp of Engineers now extensively uses ACB systems for construction of revetments that require durability and flexibility by virtue of conforming to varying surface contours in an efficient manner, which would otherwise be a challenge for soil displacement.

Another important application under floodwater management comprises ACBs for water channels. Due to their increased permeability and hydraulic efficacy, they stand very well in managing stormwater in both urban and industrial areas. It is reported that ACB systems can reduce surface water runoff by as much as 30%, leaving behind protection for critical infrastructure against urban flooding.

Besides strengthening infrastructure such as roads, bridge abutments, and levees, the ACBs provide for a modular installation that can take place with a 25% reduction in labor costs and time compared with traditional methods. More cost effectiveness and least maintenance [are] ensured in the longevity of ACBs that lasts for 30 years under proper conditions.

The acceptance of ACBs for sustainable infrastructures across wide design and environment management projects worldwide is rapidly picking pace due to the adaptability of the eco-friendly factors and applications that are tested and proven well in final applications.

Benefits of Articulated Concrete Block Mats

The benefits of articulated concrete block mats include durability, minimum maintenance, and a long working life. Moreover, they offer ecological advantages and feature great flexibility in use, which thus makes them suitable for numerous construction and environmental management applications. They have also found acceptance in numerous critical projects, demonstrating their promise in sustainable infrastructure solutions.

Durability and Longevity

Articulated concrete block mats can resist heavy environmental conditions and, as such, find application in erosion control and infrastructure protection as one of the most durable. According to recent data, ACB mats respect the criterion of functioning for over 50 years with almost zero maintenance under major conditions of severe weather, withstanding high flow velocities and stresses from other antagonistic forces. Solar ultraviolet degradation resistance and chemical resistance also contribute largely to the longevity of ACBs and their continued functioning through the years.

Case studies have recently shown the capacity of ACB mats to hold their structure under high hydraulic stresses and in fact did resist water flows of velocities greater than 20 feet per second in some applications. This strength affords it immense applicability on various riverbanks, spillways, and other erosion-prone areas. Furthermore, the modular system and interlocking nature of these mats give them greater stability and consequently reduce the frequency of failure of the system over the years.

Erosion Control

Erosion control is important in conserving landscapes, preventing sediment from polluting waterways, and sustaining infrastructure. With regard to Articulating Concrete Block (ACB) mats, erosion control gets a new dimension of permanence, flexibility, and ecological benefits. It has been shown in recent research that the porosity of ACB systems can be as high as 20%, thus allowing vegetation growth through the voids while simultaneously controlling water flow and limiting erosion processes.

Data also support its use to reduce soil displacement in areas at risk. For instance, performance analyses from hydraulic engineers indicate ACB mats have withstood shear stresses greater than 10 pounds per square foot, which would otherwise contribute to severe soil instability. Being lightweight and yet sturdy, they have eased the installation process and reduced total construction costs, with some projects reporting as much as 25% less time in installation than traditional erosion control measures.

The adaptability of modern ACB systems also extends the scope of their application to a variety of terrains and ranging from steep slopes to coastal shorelines. With the right design variables and specifications for installation, these systems will provide a long-term solution that would meet both engineering standards and environmental legislations, thus allowing sustainable development across erosion-prone areas.

Environmental Benefits

Articulated concrete block systems would have strong environmental advantages, thus constitute a sustainable option in erosion control. Due to the permeable interlocking design, ACBs encourage natural infiltration of water to recharge groundwater supplies, thereby reducing surface runoff and elimination of the risk of downstream flooding. Studies indicate that the rate of soil erosion is reduced by up to 90% in protected areas compared to unprotected ones under these systems, thus laying a solid foundation for protecting regional ecosystems and soil health.

Another factor is the fact that ACB systems can be produced with recycled materials that reduce the carbon footprints of the materials during manufacturing. Using local materials and reducing the transportation of the components within great distances well promote green construction approaches. Besides, these systems facilitate vegetation growth by means of their open cell design, thereby advancing green infrastructure. Recent research reveals vegetated ACB configurations can mutually assist in enhancing habitat quality and sequester carbon, offering a double-edged solution to erosion control and ecological restoration.

Applications of Articulated Concrete Block Mats

The applications of ACB Mats are many and varied: slope stabilization, shoreline protection, and erosion control in channels and watercourses. Their versatility, coupled with the ability to support vegetation, makes them a viable option for many structural and environmental problems.

Coastal and Riverbank Protection

There lies the problem and purpose of coastal and riverbank protection and maintenance against erosion with vulnerable landscapes: An Articulated Concrete Block (ACB) system. Beyond the scope of a few months or years, shorelines and riverbanks face erosion of approximately 1-6 feet per annum due to sea-level rise, currents, and heavy rainfall. ACB Mats try to counter these challenges by presenting a resilient yet flexible layer of protection that conforms to shifting grounds.

It has been observed that areas treated with ACB Mats have demonstrated a far more diminished rate of soil erosion: around 70 percent less sediment loss than adjacent lands that remain unprotected. For example, a project conducted along the Mississippi River confirmed that the use of ACB Mats had not only stopped further erosion but also helped vegetation regrowth within one year of installation, thereby giving the area ecological benefits.

These Mats also resist extreme weather conditions such as hurricanes and floods. With capacities exceeding 5,000 psi (pounds per square inch), they also allow water permeability for root growth, providing a double-edged sword for the protection of infrastructure and ecosystems. Hence, ACB Mats become critical tools in combating climate change impacts and preserving crucial environmental landscapes.

Road and Bridge Construction

Both the durability and sustainability of infrastructure are considered alongside the use of these mats in road and bridge construction. Erosion control technologies, including ACB Mats, are predicted to witness an upward trend at a 7.2 percent CAGR from 2023 to 2030 globally. This indicates greater emphasis on solutions that stand resilient amid climate challenges.

A profusion of benefits are ushered in by ACB Mats in road and bridge construction: besides deterring erosion of soils around abutments and scour at piers, the major causes of bridge failures, tests have demonstrated that this matting eliminates up to 85% of hydraulic shear stresses, thereby greatly improving the general life expectancy of infrastructures. They are much quicker to install due to the system being modular; it concludes the period of construction by a whole 30% in comparison to the traditionally used methods.

Scientific and technological progress has augmented the environmental effects of the ACB Mats. This permeability provided by the mats encourages vegetation to regrow, marrying solid engineering with ecological restoration. In Florida, for example, ACB Mats were used along a highway to stabilize a flood-prone area, resulting in more than a 40% reduction in maintenance costs, alongside fostering biodiversity in the adjacent wetlands. These examples speak seriously of the capacity of the ACB Mats to meet the demands of engineering and environmental concerns.

Landscaping and Aesthetic Use

ACB Mats are not at all considered a mere functional method for landscaping. Their design will allow for grass and other vegetation to grow through the apertures and join the natural surroundings. Such studies conclude that in an urban setting, installation of ACB Mats in green areas considerably decreases soil erosion and maintains their visual appeal. Areas installed with ACB Mats have seen a 30% increase in vegetation cover within a year, aiding biodiversity.

Moreover, this kind of mat can be used for landscaping in varied projects, like parks, riverbanks, or urban greenways. Recent acknowledgments from environmental engineers record that sustainable urban design incorporating ACB Mats can cut infrastructural maintenance by as far as 25%, and boost the structure’s ability to resist water damage. The option of ACB Mats provides the right balance between nature and long-term economic viability, ideal for today’s landscaping projects.

Installation Procedure for Articulated Concrete Block Mats

In my opinion, ACB Mats have their rightful place within sustainable urban design because they contribute to a reduction of up to 25% in maintenance costs while simultaneously improving the life-span of civil infrastructure in water-related areas; hence they really achieve the balance between environmental consciousness and economic good sense.

Site Preparation and Planning

Effective site preparation and planning are the most fundamental steps in the ACB mat installation process. Initially, the installation starts with site-condition investigation, looking at soil conditions, slope stability, and possible water flow patterns. Recent researches indicate that such site investigation would reduce installation faulting by 30%. As an example, with the slope angle maintained higher than a certain value, erosion shall be out of the way while at the same time, the functioning of the mats is truly realized.

Environment-friendliness should be incorporated into the factors considered during planning to minimize ecological disturbances. According to information given by Google Search, the use of some geotextile materials during installation keep the soils well-filtered and prevent them from displacing sediment, thereby improving ACB’s overall efficiency by some 20%-40%. Other aspects of planning include the quantity estimation of materials, choosing the correct types of mats for the conditions in the area, and considering any local regulations that may impact installation. A satisfactory plan would, even more, ease the installation and extend the mat life in tougher working environments.

Steps for Proper Installation

Site Preparation

Proper site preparation lays the basis for a successful installation of ACB systems. Clear the site for all vegetation, debris, and obstructions. Excavate and grade to the suitable slope and contours so as to ensure stability. According to research, improper grading may cause the efficiency of the system to decrease by somewhere around 30% as time goes by.

Subgrade Compaction

Compaction of the subgrade increases the strength of the foundation base thereby reducing the chances for the great settling to appear after installation. Best practice methods suggest the achievement of 95% compaction of relative density recorded against the standard soil tests. Excessive compaction will allow the formation of voids under the mats, thereby compromising the effectiveness of the system.

Geotextile Layer Installation

Unfold geotextile material over the compacted subgrade to encourage water filtration and to restrict erosion. Nonwoven geotextiles have been studied recently to improve filtration by 25% more. Lay the fabric smoothly while ensuring an overlap of at least 12 inches at the seams.

ACB Mat Placement

Place the articulated concrete block (ACB) mats into their final position carefully, in accordance with the design plan. Use control machinery or manual methods to lower the mats to the bottom without disturbing the subgrade. Recent innovations in ACB design with interlocking configurations lend to the improvement of hydraulic performances and, shear resistance, which are increased by 50% in the best case.

Anchoring and Edge Treatment

Anchor the mats with stakes, anchors, or other approved methods to ensure their stability during high flow events. Give special treatment to the edge of the installation with trenching or thickening, as edge sealing will help in preventing undercutting, hence increasing the lifespan of the system.

Post-Installation Inspection

Carry out a detailed inspection on the completion of installation. Look for the alignment, anchoring, and any defects that might be visible. Post-installation hydroseeding could also be considered for the exposed areas to further stabilize the surrounding soils with vegetation. Data indicates that such vegetative stabilization can reduce erosion rates by 75%.

The precision and attention to detail in applying these steps will translate to a long-lasting and highly functioning ACB system. The effectiveness and longevity of these systems can further be enhanced by applying the newest in materials and engineering insights.

Maintenance Tips for Concrete Block Mats

Maintenance work mainly consists of regular inspections to assess any damage or displacement. The debris shall then be removed to avoid blockage, and vegetation shall be controlled to prevent root interference. Minor repairs should be carried out as soon as possible so that the system continues to function properly.

Regular Inspection Practices

Regular inspection of concrete block mats will ensure their durability and efficaciousness. As per the industry standards, inspections should be conducted at least twice a year, preferably in spring and fall. Other inspections should be carried out following certain weather events: heavy rains, floods, and so forth. The area under investigation should be chiefly concerned with detecting indications of shifting, cracking, or erosion beneath the blocks. Data show that failure to address damages mostly leads to any given structural failure, and approximately 15% to 20% of erosion control problems originated from negligent maintenance.

Besides massive damage, debris buildup could also hurt performance. It was studied that cleaning debris fosters up to 30% improvement in water flow efficiency, becoming a critical maintenance concern. The debris can be rinsed off by either pressure washing or hand-scrubbing with wood or wire brushes to remove sediment and organic materials entrapped between the blocks. If this maintenance method is continually implemented throughout its useful life, it will extend the lifespan of concrete block mats by several years, thus yielding cost-effective and sustainable application.

Cleaning and Repair Procedures

In the pursuit of best repair results, developing and utilising further advanced modern cleaning technologies and techniques have become of paramount importance in maintaining concrete block mats. For example, in recent industry data, the usage of high-powered rotary surface cleaners together with environmentally friendly detergents has been said to increase the cleaning efficiency by up to 40% over traditional methods. These tools attack embedded dirt and grime whilst not compromising the structural integrity of the blocks.

When it comes to repairing for any cracks or damaged block replacements, a polymer-modified mortar is recommended by experts. This type of mortar offers better bonding strength and greater durability for extreme weather conditions. Construction maintenance reports show that joints that are regularly sealed with waterproof sealants lower the possibility of water infiltration by 25%, thus greatly minimizing the damage with time. By combining advanced tools and materials with routine maintenance concepts, the concrete block mats can be brought to a new level of performance and longevity.

Longevity Enhancements

In improving the longevity of concrete block mats, advanced material science and construction methods shall be employed. Modern innovations in the form of high-performance concrete mixtures and polymer-modified overlays have been proven capable of resisting cracking and surface deterioration for long periods. It has also been shown that the incorporation of fiber-reinforced concrete would boost structural durability by about 40%, as it reduces stress-induced cracking during load fluctuations and thermal changes on a concrete surface. Corrosion-resistant coatings and sealers are also established to extend the life of concrete surfaces by reducing water ingress and protecting them from chemical degradation.

As such, predictive maintenance using modern technology such as infrared thermography and moisture sensing provides another solution. According to industry data, the integration of such technologies can make early detection of wear and tear, thus lowering the cost of repairs by almost 30% throughout the whole lifetime of the structure. Furthermore, sustainability-based approaches, such as using recycled aggregates, have also been cited to hold the integrity of structures intact while forcing down carbon emissions associated with conventional concrete production. This blend guarantees that the concrete block mats are accepted by modern construction demands while simultaneously factoring in their economic consideration and green emphasis.

Reference sources

1. Development of an Articulated Concrete Armor Unit Against High Waves and Uneven Slopes

- Authors: Wan Hoon Lee, Yeosub Lee, Changhwan Jang

- Journal: Journal of Measurements in Engineering

- Publication Date: September 8, 2024

- Summary: This study presents the development of a new articulated concrete armor unit named Couple-Lock, designed to withstand high waves and adapt to uneven slopes. The research includes hydraulic model experiments that assess the unit’s performance under various wave conditions, demonstrating its effectiveness in coastal protection applications. The findings indicate that the Couple-Lock has a high stability factor and favorable reflection and transmission coefficients, validating its feasibility for use in marine environments(Lee et al., 2024).

2. Study on the Application of the Articulated Concrete Block Mattresses Method as Subsea Pipeline Protection

- Author: Hamzah Hamzah

- Journal: Collaborate Engineering Daily Book Series

- Publication Date: December 28, 2023

- Summary: This paper discusses the use of articulated concrete block mattresses (ACBMs) for protecting subsea pipelines from environmental forces such as wave pressure and tidal currents. The study highlights the hydrodynamic performance of ACBMs and their ability to adapt to seabed undulations, making them a viable solution for subsea pipeline protection. The research emphasizes the importance of ACBMs in preventing damage to underwater infrastructure, thus supporting their feasibility in practical applications(Hamzah, 2023).

3. On the Simulation-Based Quantification of Energy Dissipation in Rockfall Protection Structures: Case of an Articulated Wall Modelled with the NSCD Method

- Authors: Stéphane Lambert, Ritesh Gupta, F. Bourrier, V. Acary

- Journal: Rock Mechanics and Rock Engineering

- Publication Date: November 12, 2024

- Summary: This research focuses on the simulation of articulated walls, which are similar in concept to ACBMs, for rockfall protection. The study quantifies energy dissipation and stability under dynamic loads, providing insights into the structural performance of articulated systems in geotechnical applications. The findings support the use of articulated structures in enhancing safety and stability in various engineering contexts, thereby validating the feasibility of ACBMs in similar protective roles(Lambert et al., 2024).

Frequently Asked Questions (FAQs)

What is an articulated concrete block mattress?

An articulated concrete block mattress is a flexible and permeable erosion control system composed of rectangular concrete blocks joined together. These blocks absorb wave action and oppose erosive forces, hence being suitable for shoreline, canal, and underwater pipeline protection.

How do articulated concrete block mats help in erosion control?

Articulated concrete block mats protect against erosion by permitting water flow through the gaps between the blocks while safeguarding the soil beneath. The structure dissipates the energy of waves and lessens the effect of high-velocity water flows, thus lessening the potential for erosion in susceptible areas.

What are the benefits of using concrete block mattresses for coastal protection?

Concrete block mattresses that resist erosive forces are beneficial for coastal protection since they are durable, can stand severe environmental conditions, and are flexible enough to conform to shoreline changes. Moreover, these mats are fast to deploy and stand to prevent damage from wave action, ship wakes, and wind waves.

Can articulated concrete block systems be used on underwater pipeline protection?

Articulated concrete block systems are often used to protect underwater pipelines. The mats provided stability and protection against erosive forces that can damage the pipelines, particularly in areas exposed to frontal attack by waves or from high-velocity flows.

How are block mats normally deployed?

Normally, block mats are deployed by arranging them in a series of compartments linked by an interwoven perimeter. This arrangement allows the mats to form a mattress of pillow-shaped concrete blocks that conform to the underwater topography and thus prevent erosion effectively.

How do articulated concrete mats conform to changes in the environment?

Articulated concrete mats are flexible and can adapt to variations in the underwater landscape. This ensures that they remain effective in providing counteraction against erosive forces that may otherwise change their characteristics over time.

What materials are used in the construction of concrete block mattresses?

Concrete block mattresses are normally built using high-quality concrete reinforced with polypropylene or other materials that enhance their durability and resistance to erosive conditions. The usage of such materials allows the mats to withstand environmental challenges, like wave action and soil erosion.

What type of engineering considerations are involved in using articulated concrete block systems?

Engineering considerations during the use of articulated concrete block systems include the local hydrology, soil conditions of the area, and the specific erosive forces that the project could experience. With the knowledge of these factors, the protective system would be designed to suit the location’s needs effectively.