Successful operation of the heavy machinery needs intervention in the locations that present challenges as far as access is concerned. Construction activities, oil and gas exploration areas, and renewable energy sectors are likely to experience delays due to sites that are located in areas with acute topographies. In such a way, the composite access mats are so designed that they cater for every difficult site by either enabling or providing protection. Later on in this text, we will elaborate on why composite access mats are useful in the management of grounds, the advantages of the said equipment, and the reasons why this product is very popular. Also, you will get acquainted with the factors that support the application of such complex equipment and how it can enable you to accomplish your work.

Understanding Composite Access Mats

What is a Composite Access Mat?

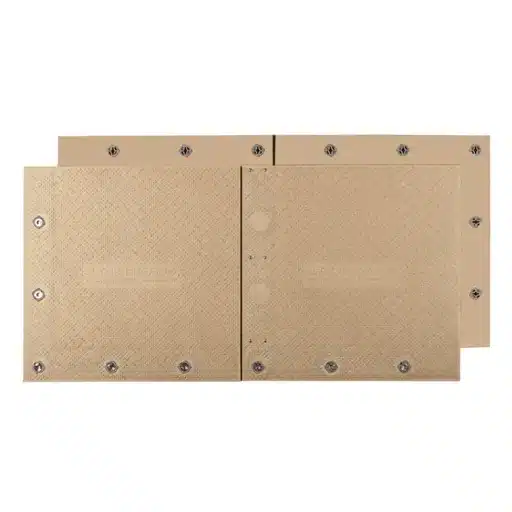

There is a structure called a composite access mat, which is made out of synthetic materials in their best forms, that is very supportive and stabilizing in almost every setting. It’s a sturdy yet simple structure. Unlike wooden mats, which are mostly used, composite access mats are made out of complicated materials such as high density poly ethylene (HDPE), which makes them lighter, stronger, and keeps them from being absorbed by water, chemicals, and any other external influences.

It is different in different areas like construction, energy and utilities or events…these are mats that are used to create temporary pathways over populations when there are areas to be protected, and also where heavy equipment is being operated. They are quite useful when digesting areas that are not level, which are clayey/muddy or soft soils, and yet demand construction or heavy activity.

According to current statistics, engineered wood structures are on average 50% less durable compared to composite access mats, which reduces the costs of repair and reduces environmental pollution. Additionally, another disadvantage of composite access mats is the fact that the jigsaw panels have rather flat and wide surfaces that pose challenges to persons and machines from slipping. This is one of the biggest advantages of composite mats since it allows reusing them plus there is no concern of adverse effects to the underlying soil in the sensitive places, such as matted. Therefore, it is appropriate for use in the case of ground protection for heavy construction, which is effective and long-lasting.

Key Features of Composite Mats

- Durability and Strength

High-performance stability, under extreme loads and weather conditions, Composite Mats provide the best fit for construction, oil and gas, and utility infrastructure sectors. For example, most reliable products have a carrying capability of up to 600 psi, which would mean a belt for cranes and drilling equipment which would be such that would not move. - Easy to Install and Lightweight

Composite mats are light despite the strength they add to a surface, unlike steel or heavy timber mats. This means that they do not incur as much cost in terms of logistics and hence come in handy for installations. An example is that it reduces the installation by 40%, thereby improving efficiency. - Longevity and Affordability

Although the initial cost, when you purchase composite mats, is fairly high, the mats are not susceptible to wear and tear. Their lifespan is usually longer than 10 years, unlike conventional materials. The period composite access mat wear does not add to overhead costs. - Environment-Friendly and Sustainable

Recyclable materials are increasingly being used in the fabrication of mid-composite mats. It also applies to the mat itself. Meaning that the extent of harm inflicted on nature is generally less. Furthermore, there are hints through study that with its use, it is possible to reduce the need to establish areas of erection in certain modifiable areas by at least seventy-five percent as compared to other materials. - Safer Work Environments

The fundamental objective of the composite mat is to ensure that slip-resistant surfaces are provided, together with the interlocking structure to avoid people slipping/tripping as a result of working on, for example, unstable surfaces. Consequently, it generally contributes in the reduction of cases of work-related injuries and cost-related matters for the most part.

Regardless of whether those practical functions are imposed in construction or not, the issues of wooden slopes and what is done to achieve the latter, without extra durability to the base, are addressed. Thus, this entails cost-effective and environmentally friendly benefits that cut across sectors.

Comparison with Traditional Timber Mats

Businesses in need of ground strengthening can be sure that these exceptionally functional mat alternatives have advantages over the conventional wooden mats and are, therefore, useful. The first point of distinction is the durability of the materials. Many composite access mats tend to be made from polyethylene or a different plastic with a tensile strength high enough for almost 10 years, unlike when using timber, which can obviously split, rot, and perhaps bend, necessitating a change after about 3-5 years.

However, in the case of wood, it is equally important to note the other nonstructural considerations that make wood dangerous on-site. This is because wooden mats tend to absorb some water and eventually weaken or get even contaminated, whereas this does not apply to composite access mats, as they remain effective at several degrees of temperature even in the presence of water and some chemicals. Ex: if the environment is kept at cold or warm temperature, it does not affect the structure of these composite mats, and hence, as expected, the performance is maintained at any of the temperature conditions.

When compared, the two materials also have different properties in terms of weight and convenience while in use. The authors also highlight that the seamless timber surfaces unmilled accounts are heavier than the fully bound composite surfaces, which results in a 40 per cent reduction of the transportation costs. In addition, since the crackers are designed to interlock with one another, the steps taken in mounting are so time-consuming and risk-free that after the armed forces members, less time is consumed to finish the projects. By contrast, the mats that are made of timber are rather bulkier and need more manpower for their deployment, meaning that there are issues with both transporting and handling these mats.

In matters of environment, it must also be pointed out that composite access mats also fare better than the common timber mats. Composite mats are also an aspect oppose the traditional mats used for construction in that they benefit the environment as waste plastic materials are used in their manufacture. And as for conventional wooden access mats, what is the use of trees in a mature forest if not to chop them up in order to make more wooden mats.

Economically speaking, composite materials may prove to be expensive at the start but emerge less expensive overall in the end because of their long life and the least maintenance they require. Also, it has been observed through the studies of businesses that make use of composite access mats instead of timber mats that, in the long run, these businesses manage to make 30% to 50% saving on the expenditure spent due to these practices, since the replacement of these access mats, transportation, and other workforce is less.

When all these factors are considered, it becomes apparent that the composite access mats provide durability, cost-effectiveness and save the environment, and so it becomes easy to replace them with the timber access mats in modern-day industries.

Benefits of Composite Access Mats

Durability and Reliability

Thanks to the fact that composite access mats are manufactured with materials that have been synthesized to endure high pressures and the harsh environmental conditions, they are used in construction, oil and gas, renewable energy, and several other activities. Recent surveys state that composite access mats and certain others can last for more than 10 years, whereas wooden ones, by contrast, often require changing within 1-3 years. Consequently, it eliminates any working delay or replacement that might still crop up during the enclosed years, enhancing the attractiveness of the business instruments.

Moreover, other advantages of composite mats relate to resistance to environmental conditions like moisture, chemical substances, temperature changes, and others. For instance, there are data on composite mats, which suggest that they do not lose their stability within an operating temperature range from -40°F to 140°F (-40°C to 60°C). This makes them versatile and trustworthy in a lot of climates and applications. In addition to that, they do not absorb any water, chemicals or other materials, which eliminates warping or fouling of the mat, thus translating to continued operations while adhering to the environmental rules.

Thanks to the use of high-end materials as well as the latest technology in the development of composite mats, they have been proven to be superior when compared to the conventional ones, thus providing the industries with a tough and firm solution in regard to ground protection.

Environmental Impact and Sustainability

Composite mats not only assist in operations but also aid to a great extent in the preservation of the environment. As opposed to typical wooden mats, which often cause the clearing of trees, composite mats come from old products or high-grade polymers that are recyclable once they serve their purpose. Research indicates that industries that make use of temporary ground mats experience a 25% decrease in the degradation of forests owing to the application of composite models.

Furthermore, it increases the longevity of mats so that to be able to do their purpose, lowering the need to change and subsequently generating less wastage in most industries. There is evidence that conventional wooden mats will require replacement in 4-5 times’ use compared to composite access mats, which could be used 10 times less frequently than them, thus minimizing both raw materials and costs.

Additionally, mats manufactured from composite materials are easy to carry, yet are quite strong; this means less fuel is used in transportation. For example, research indicates that in transportation services, every 10% reduction in weight allows savings of up to 1,000 gallons of fuel in a year for major projects. This reduction in energy consumption translates to fewer emissions of carbon dioxide, which is another step towards global sustainable development. More importantly, with changes in recent times towards durability, reusability, and environmental concerns, composite mats not only meet current business demands but also ecological expectations.

Cost Effectiveness in the Long Term

Not only are composite mats good performers for various industrial applications, but they also prove highly effective as cost-saving options. Decent data is crying that the composite mats cost, which are relatively higher in comparison to the old-fashioned wooden mats, the replacement costs are significantly lower, thanks to their life, which is about 3 to 5 times longer than wooden mats. Transportation of these mats is cheap since they are lightweight, and cases have been reported where construction projects have achieved savings of over 30 percent of transport costs in shipping the mats. In addition to the results of the aforementioned study, there was another one that concluded that composite mats’ reusability is at approximately 80%, and this has a significant impact on lowering the costs, specifically the cost of having to purchase mats.

Moreover, composite mats can reduce the maintenance costs, as they are weather, chemical, and wear-resistant and require less maintenance; hence, they provide more savings over their usage period. In fact, studies have shown that firms that use composite mats record savings of as much as hundreds of thousands of dollars every year in projects that are carried out in such adverse regions. It is these prolonged financial benefits that make investing in composite mats an attractive proposition for the performance- and cost-conscious sectors.

In the same way, composite access mats always come with the advantage of cost, saving a lot of maintenance costs while being used. Indeed, research claims that companies in the business of deploying composite mat facilities report saving several hundred thousand dollars each year in harsh, unconventional project territories. The promise of these lasting financial gains contributes to the attractiveness of investing in composite access mats for economic and performance-conscious businesses.

Applications of Composite Access Mats

Ground Protection for Heavy Equipment

The use of heavy machinery could damage the ground surface, and because the subsoil is quite sensitive, measures to control its compaction destruction will be required in the form of composite access mats. Following this trend, it is anticipated that the increase in global composite mats market size will enable it to gain a 6.5% CAGR over the period from 2023 to 2030 due to the further development of these structures and trends of growth in the construction, gas recovery, and utility industries. Therefore, even the heaviest weights like cranes, excavators, and drilling rigs cannot break those mats because they sometimes weigh more than 600 PSI and help to distribute the load evenly.

Other researchers have also suggested that composite mats can help avoid degradation of some ecosystems, like wetlands and forests, as they provide a stable surface that may be reused. While traditional wood-based mats often splinter and degrade rather quickly, at about 10–15 years in the useful life of a mat, the composite mats need not suffer the same fate.

Thanks to the advancement in technology, there is an emergence of interlocking composite access mats that require minimal effort to assemble and have a no-slip surface that provides additional safety to those working in the sites. In addition to these advantages, some of these technologies can also withstand weather conditions, hence they are in a category of tools that help in site management and operations in each region.

Use in Crane Operations

The provision of composite access mats is well applicable to crane works, as these devices service the cranes where there is no adequate grounding layer for mechanical bearing of bearing machinery, because they aid the propagation of crane or any other utility load over the surface. This, in turn, reduces load concentration within the apparatus as its feet get into or damage the ground. For instance, research conducted demonstrates that high-quality mats are capable of supporting loads weighing more than 250 tons, which are essential for stabilizing the cranes during operation.

Market research reports indicate that, for one, the use of composite access mats will cut down project overruns resulting from soft soils by about 40%. Its means that they are an effective mode as precious time is not only saved but also work is accomplished at a faster rate. Moreover, the robust and lighter design makes it easier and quicker to set up than ordinary wood mats. Advances in material science have also helped in developing ultraviolet and chemical-resistant coatings that withstand the harshest of conditions.

The enticing benefits that composite access mats bring have cut short high maintenance expenses on the part of every company that buys heavy equipment access on irregular terrain. Also, these mats have further addressed the issue of the environment, including the formulation of relevant policies, because many composites are manufactured from (recycled) materials that offer the same performance. Thus, composite mats proved to be a vital part of the modern-day crane lifting equipment.

Common Applications in Various Industries

The need for composite access mats is great in many fields because they are very practical and durable. In construction, for example, one of the uses of mats is for placing cranes and other heavy equipment on uneven or muddy terrain, thus minimizing the risk of injury. Recent studies indicate positive growth in the construction industry, with a 4.2 percent projected growth, which validates an increase in the need for crane mats.

These mats are equally very significant for the oil and gas industry, whose major operations are often in rural areas and hostile environments. 30% increase in efficiency as compared to the usage of wooden mats has also been tied to the composites, due to the concepts of reduced downtimes, which saves a lot of resources. Any industry, and particularly the renewables, such as the wind farm turbines for instance, could never avoid the use of crane mats for construction. They protect the site and allow the contractors to rapidly complete the projects, something important given the rise of renewables such as the US’s 30 GW of offshore wind by 2030.

They effectively depict the importance of the use of composite access mats to satisfy the requirements of each industry. Therefore, they have to be basic instruments in improving, sustaining, and conserving plants more healthily and efficiently.

Choosing the Right Composite Access Mat

Factors to Consider

Several important aspects must determine the qualifying composite access mat for the given application requirement to ensure an optimum standard of operational performance and price efficiencies. Listed here are prime features, supplemented with the latest data and insights:

- Bearing Capacity

Bearing Capacity is the basic property of any composite mat. Should industries be considered wherein construction, oil & gas, or renewable energies may require equipment? Such equipment may possibly be tens of hundreds of tons by weight. Modern composite mats are designed to sustain distributed loads as high as 600 psi or more, which makes them capable of providing a reliable solution to heavy machinery and vehicles. For instance, the company leader’s MAT435 greatly strengthens the position for being capable of preserving hardened strength and maximum flexibility in extreme conditions. - Environmental Impact

Composite mats work as a green substitute to conventional wooden matting, wherein materials used for their construction are commonly high-density polyethylene (HDPE) or other recycled materials. A recent study showed that these mats outlive their wooden counterparts by at least five times and lessen the burden of a constant need for similar investments. Their weather-resistant and non-absorbent quality decreased the chances of environmental pollution due to their imperviousness to ecological disasters by stopping the flow of harmful products, such as oil and chemicals, between worksites. - Durability and Weather Resistance

The industry operates in extremities of climatic variation. Composite mats are designed to cater to hot, scorching temperatures or cold conditions without any warping or ever splintering. With UV-resistant mats of various temperature insulating functions for regions of the Gulf Coast and into the Arctic, companies can choose extreme reliability between a range of -40°F to 140°F. - Ease of Transportation and Installation

On such huge projects, cost can escalate simply due to transportation and installation processes for heavy timber matting. At a 40% discount rate, transport costs are reduced due to the interlocking design and the light composite materials of this innovative access mat when compared with more traditional ones. Since the concept, they can be assembled quickly, which covers a significant expanse of ground. - Project-Specific Requirements

When considering access mat applications, different projects require access mats with different characteristics in design. For instance, wind farm projects seek access mats that guarantee minimum ground pressure—essential for fragile ecosystems. All else being equal, matting suited to the specific condition of the site is vital for the appropriate control of projects, an example of this being the PVC mat with a high chemical resistance used for wildland oil and gas spill cleanups in an earlier case. Understanding the requirements of your project represents a tailored choice according to the particular needs. - Long-Term and Cost-Efficiency Measures

The investment in synthetic mats is relatively high as compared to wooden mats, but they actually translate into comparatively lower maintenance needs, together with a possible chance of recycling them, resulting in their economic efficiency and profitability. Case studies have shown that in some cases where clients made the change concerning mats from wooden to synthetic, literally 30% savings, often approximately up to 10 years, were seen in total access mat bills due to the great durability of composite mats.

Careful consideration of these important issues, coupled with cutting-edge technology advancements in composite mat material application, serves to improve operational safety, improve efficiency, and enhance sustainability. This leads to strong project outcomes.

Medium-Duty vs. Heavy-Duty Mats

Hence, the intended storyline was upgraded since medium-duty and heavy-duty mats are the essential distinctions between the proper access mats. Light yet cost-effective medium-duty access mats are meant to be used only with light equipment, where the weight restrictions are more lenient. Typically, they are constructed of such composite materials or light wood types and are well-suited for accessing temporary construction roads where the stakes are not high at all things like small construction jobs, utility checkups.

By contrast, the heavy-duty mats carry the knack to carry the heaviest of the machinery, including cranes, heavy excavation equipment, as well as a wide variety of other heavy industrial equipment. Made completely from HDPE or enhanced with steel, the heaviest mats are capable of carrying loads stronger than 600 psi. For instance, some of the composite heavy-duty mats can carry loads much larger than 200 metric tonnes, and therefore, they will be very useful in an oilfield or in mines and for any occupation that is considerably burdened.

The comparison shows favorably on composite mats in comparison with hardwood mats. They say that such mats have a minimum lifespan of a little over 10 years compared to 3-5 years for the comparator of wooden mats. The weight of the composite mats is also another very critical point of their own, because it is light compared to that of the wood mats. Engineered wood lowers shipping costs by about 40%, which stands as a huge advantage in large-scale projects.

Really, the variables affecting the choice of medium-duty versus heavy-duty mat units are closely scrutinized according to on-site operational requirements, such as the weight of equipment to support, the frequency of usage, and the type of terrain. Therefore, the enhancements to such materials will give the best performance and thus reduce costs; these reductions in turn, ensure a more sustainable industrial site management.

Site-Specific Requirements

In making a selection of operational mats, consideration of the site’s specific environment is necessary, including the nature of the terrain, depths to refusal, and any stringent regulations prohibiting certain practices. The recent study further suggests that the global construction mats market will grow between 4-5% percent by the year 2023-2030 since there is an ever-increasing demand from the industry and the exploration sector all over the world.

For instance, in the oil and gas sector, very heavy-duty mats are applied to cover heavy equipment exceeding 100 tons and are hence very essential in retaining any such equipment over soft or hilly ground. On the other hand, medium-duty mats are quite suitable for construction purposes, which do not imply heavy stresses and facilitate these things in terms of ease of repositioning and removal. Moreover, the increased wear resistance property of high-density polyethylene slabs has also restricted the operator by prolonging the effective use of composite access mats by 30%, resulting in fewer replacement cycles and thus, reducing costs incurred.

In addition, the percentage of recycled materials used in the manufacturing of mats, as adopted within the two years preceding the date of the industry’s report, has also increased by 12%. This integration is necessary since it benefits every hierarchy, including the carbon emissions discussed above, besides the existence of stringent requirements, especially in sensitive or protected environments. These contribute to the need for design customization of composite access mat solutions for the sake of the project location, increasing efficiency, and protecting the environment as well.

Reference Sources

1. Stress analysis of geosynthetic access mat systems over weak subgrade

- Key Findings: This research evaluates the performance of geosynthetic access mats in providing vertical resistance and supporting heavy construction equipment on weak subgrades. The study highlights the rigidity and effectiveness of these mats in challenging terrains.

- Methodology: Stress analysis and modeling of geosynthetic mat systems under various load conditions.

Read more here

2. Timing and duration of access mat use impact their effectiveness

- Key Findings: This study explores how access mats mitigate soil compaction and their impact on grassland recovery, particularly in sandy soils.

- Methodology: The research analyzed the effects of timing and duration of access mat use on soil and vegetation recovery.

Read more here

Frequently Asked Questions (FAQs)

What are composite access mats made of, and why are they preferred for heavy equipment use?

Composite Access panels possess heavy-duty polyethylene plastic and some complicated plastics. These materials provide high strength with low weight as they are resistant to water chemical and climate. Composite mats are used under heavy machines to support the beautiful landscape where ordinary soil would buckle. Unlike conventional wooden mats, Composite mats do not tear and wear easily, do not require any maintenance, and are green, which makes composite access mats an ideal choice for constructing sustainable pathways.

What are some of the ways composite mats advance ecological sustainability?

Disruption of the environment that ordinarily accompanies the building process as well as most industrial project development, is realized by the use of composite mats, which do not damage the ground as much and are the most likely intrusion into the ecosystem of great value. Maximum utilization of the same mats in various projects significantly diminishes the generation of waste when compared to wooden mats that are designed specifically for a single project and are to be disposed of afterwards. At the same time, they do not cause an alarm in resolution concerns since marks left by composite access mats do not have any residues or poorly placed signs on the surfaces, which conforms with environmental regulations, especially those dealing with environmentally sensitive areas. For this reason, they are a sustainable alternative for anybody seeking action in the interim.

Would composite access mats be durable in harsh climatic environments?

Yes, composite access mats are built to withstand even the harshest of climatic conditions and do their job effectively. The mats are made of moisture, weathering, temperature, and UV-resistant materials that do not warp, rot, or disintegrate with harsh environmental elements. This makes the mats very preferable for areas and projects, where weather changes, such as heavy downpour, snow, or scorching temperatures, may make it difficult to work.

What are the key benefits of using composite access mats for heavy equipment?

One, composite access mats are lighter than the latter in terms of their load-bearing capacity and durability. Most exposure and usage of any heavy-duty equipment calls for a working area that is safer and more stable. This and the possibility of features which allow them to be recycled eventually in order not deplete the environment go a long way in justifying their use in a viable and attractive way throughout the years and across industries such as construction, energy or services.

Do composite mats work well in sensitive or protected ecosystems?

Yes, composite materials support is unique in that it adheres to environmentally friendly principles. It evenly distributes loads and exerts low ground pressure, thus protecting the soil and plants from damage. Due to the nature of composite materials, which do not absorb fluids or solids, this means that the natural surroundings are effectively protected to ensure safety compliance. This helps in ensuring that work sites remain intact and undisturbed during the period of operation.

Can composite access mats be customized for various projects?

Several manufacturers make it possible to tailor composite mats to individual customer needs. In this case, the size, including the increase of thickness or, for instance, the change in the connection systems in order to fit the ground or the vehicle’s weight, may be modified. The modifications allow the client to do their work on/at the site without any difficulty. In some other instances, such alterations include marking the mats or any other labelling for instructional purposes to improve on the degree of user friendliness.