Concrete Canvas is currently changing the ways of construction and infrastructure projects. The material fuses the hard-wearing nature of concrete with flexible fabric, thus providing a novel way to solve different problems across industries. If you want to reinforce a slope or line a channel or create shelters that can be deployed in rapid times, Concrete Canvas is just doing everything to replace the conventional methods with more efficiency, versatility, and ease of use. In this post, we will discuss what makes Concrete Canvas so unique; we will also look into its applications and why it has come to be the preferred material for engineers and project managers when they want an effective and modern touch. Let the tide of modernity lead you into a world where smarter construction practices are being realized on a global scale with the help of this interface!

Introduction to Concrete Canvas

Concrete Canvas (CC) consists of a flexible cement-impregnated fabric that hardens under hydration to form a thin yet durable concrete layer. It is considered one of the fastest and efficient construction methods that offers the best choice for light weight constructions and ease of installation for diverse applications. Key usages for this material include ditch lining, slope protection, and instant shelter creation, giving it the edge of versatility for crucial emergency or planned infrastructural projects.

What exactly is Concrete Canvas?

Concrete Canvas, aka Geosynthetic Cementitious Composite Mat (GCCM), is a novel construction material that basically melds some artistic concrete with fabric flexibility. Upon hydration, the fabric hardens into an extremely tough, jointless concrete layer and offers multi-purpose application versatility far and wide. It is manufactured in roll format, making it lightweight and easy to transport, so it can be very quickly deployed in adverse environments.

Concrete Canvas has been applied around the world and has been proven through many case studies. The concrete canvas benefits the channel lining, slope stabilization, erosion control, and culvert repair. Recent data from applications in international infrastructure shows Concrete Canvas solutions are up to 10 times faster to install than traditional concrete and use 95 percent less material, reducing environmental impact and labor cost. Cemented Concrete Canvas can achieve compressive strength of up to 40 MPa after installation and ensure durability for a long time even in hard conditions.

In addition, the material is acknowledged as an environmentally viable product because it uses almost 80 percent less carbon than poured concrete. Equipped with waterproof and fire-retardant features, this material is found quite useful in critical infrastructure projects like flood defenses and fire shelters. Concrete Canvas’ innovative design and proven performance have made it a game-changer for the construction, civil engineering, and infrastructure sectors.

Overview of Concrete Canvas USA

Concrete Canvas USA is set to reshape the construction and civil engineering horizons with its avant-garde Geosynthetic Cementitious Composite Mat technology. Called sometimes as “concrete on a roll,” the material blends the durability of concrete with the flexibility of fabric to provide an efficient, cost-effective, and sustainable rendering for an array of applications.

A distinct feature of Concrete Canvas lies in its ease of installation; to simplify projects, the material can be installed up to 10 times faster than classic concrete systems, slashing labor costs and project periods. Instaling a roll of Concrete Canvas measuring around 200 square feet can take less than an hour by a small team, and the cementitious layer can be activated with water only.

With a lifespan of up to 120 years, Concrete Canvas is exceptionally high-performing and the most durable product available in the industry. It has been widely confirmed to reduce ecological impact by consuming 95% less material relative to conventional poured or sprayed concrete. Other benefits include fewer resources, promoting carbon reduction by up to 80% compared to traditional concrete.

Concrete Canvas USA caters to a wider scope of industries ranging from the military and mining predominantly, to civil engineering and commercial installations. The material finds implementations in erosion control, ditch lining, slope stabilization, and retaining wall applications. With the added advantage of being ASTM-tested and meeting stringent international standards, Concrete Canvas has finally claimed its name for both quality and dependability.

Concrete Canvas USA has been fundamentally altering projects worldwide through key case studies. Examples of channel lining use have substantially reduced water loss through seepage, and culvert repairs have decreased downtime of critical infrastructure. As rapid and efficient construction solutions become more in demand, Concrete Canvas remains a trailblazer throughout industries.

Key Features of Concrete Canvas®

Concrete Canvas offers a plethora of features for it to inherently become an innovative and efficient solution to address modern construction demands. These are the main features with recent data and findings supporting each one of them:

Fast Installation

Concrete Canvas is designed for a quick install, reducing build times dramatically as viewed against traditional construction approaches. Studied to be installed 10 times faster than conventional concrete systems, it’s a good choice for construction under time constraints.

Durability and Longevity

Concrete Canvas is very durable and lasts over a period of 50 years. The surface can resist from corrosion caused by weather, UV radiation from sunlight and chemical erosion at an extreme level. It surely provides guarantee of performance in the long term even in tough conditions.

Eco-Friendly and Sustainable

Using up to 95% less material than conventional concrete structures reduces carbon emissions and wastes significantly. With its low use of materials, it also represents the greener construction effort worldwide.

Waterproof and Fire-Resistant

Once hydrated, Concrete Canvas forms a waterproof barrier and is certified to offer an excellent level of water resistance. The Canvas is also certified as fire-resistant and conforms with various safety standards worldwide.

Various applications

As Concrete Canvas is supplied in a roll format, it finds use with a variety of terrains and project requirements. It continues to find applications in slope protection, disk lining, erosion control, and mining infrastructure around the world.

Cost-Effectiveness

Moreover, great savings on project costs can be achieved throughout the construction lifetime due to the quick installation and long life of the material. Most case studies confirmed that it is from 50% less in labor and material costs.

Thus, Concrete Canvas® has been chosen as an optimum infrastructure project whereby performance, sustainability, and economy take centre stage, giving the answer to construction scenarios of today and tomorrow.

Applications for Concrete Canvas

Concrete Canvas® finds application in all sorts of constructions, from lining channels to slope protection, culvert repair, and bund lining. It gives a sturdy, swift, and environmentally friendly solution to myriad civil engineering and construction problems.

Erosion Control Applications

Concrete Canvas® performs tremendously well as an erosion control method to keep away soil and infrastructures degradation through weathering processes, runoff, and environmental hazards. Its rugged nature and fast installation procedure make it great for stabilizing slopes, protecting waterways, and eroding surfaces in difficult environments.

Recent data and studies show the increasing acceptance of Concrete Canvas® for erosion control works at a global scale. According to the industry, Concrete Canvas® could reduce installation time up to 50% versus conventional concrete solutions. It also brings an advantage of minimizing material costs by as much as 40%, with the least labor needed and less amount of heavy machinery. One cannot even discount its environmental friendliness as it consumes 95 percent less carbon dioxide while installing than conventional concrete solutions.

Due to its resilient and weather-resistant qualities, Concrete Canvas® has been preferred in areas with severe weather conditions coupled with high erosion risks, such as coastal areas, riverbanks, and the dry plains susceptible to sudden outpour. On the other hand, this makes it the most sustainable and cost-effective answer for modern erosion control, as these problems extend into the distant future.

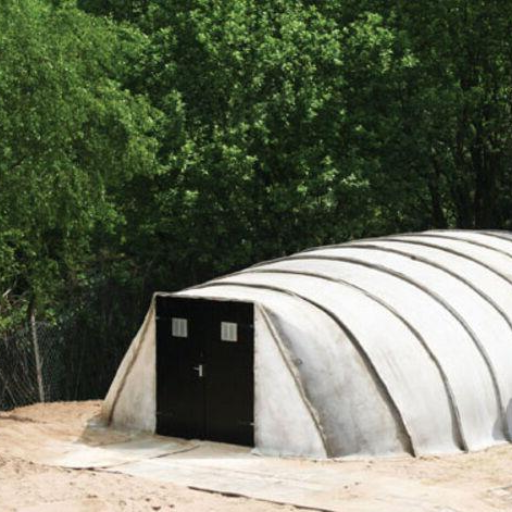

Concrete Canvas Shelters

The Concrete Canvas Shelter is an ideal concept that perfectly combines speed with efficiency and strength in rapidly deployable infrastructure, making it an excellent solution for protective shelter needs. These shelters are essentially inflatable structures covered with a layer of Concrete Canvas®, rendering them highly durable, fireproof, and weatherproof. A little after deployment and hydration, the structure sets into solid concrete within 24 hours, creating a long-term protective shelter. These shelters are very well suited for disaster relief activities, military operations, and remote infrastructure where traditional construction is time-consuming and impractical.

Recent data indicate that less than an hour with very little training is necessary to deploy Concrete Canvas Shelter, making it very time-saving compared to previous implementations. These shelters are also thermally sound, and if maintained, will last over 10 years. The studies also show the environmental impact of Concrete Canvas Shelters is far lesser than conventional procedures, utilizing 95% less material by volume and producing significantly lower carbon emissions because of the efficiency of their processes of construction and deployment. Therefore, given their use in creating safe flexible spaces in challenging environments, this makes them an absolutely valuable tool when it comes to emergency responses.

Containment Solutions

Modern containment solutions harness the most recent technologies to counter critical needs for storage and safety across industries. Common applications have been hazardous materials management, where double-walled tanks and spill containment systems prevent the contamination of the environment. Recent data suggest that secondary containment systems may be capable of containing up to 110% of the volume of the primary storage container, thus complying with strict regulatory standards such as the Environmental Protection Agency’s Spill Prevention, Control, and Countermeasure (SPCC) requirements.

Moreover, the flexible containment alternative, including modular containment berms and collapsible tanks, has gained favor because of its quick set-up in emergencies. The systems are typically made with durable and chemically resistant materials such as HDPE or reinforced PVC. Cutting-edge monitoring technology, such as smart sensors enabled by the Internet of Things, can also be integrated into containment solutions, allowing real-time monitoring of fluid levels, temperature, and potential leaks, thus further enhancing safety and operational efficiency.

These solutions not only protect the resources but significantly reduce industrial waste and environmental impacts. Industry reports subsequently put the estimate of the global containment market at beyond $10 billion by 2030, boosting the demand for such proven and sustainable solutions across sectors like oil and gas, agriculture, and water treatment.

Advantages of Using Concrete Canvas

Concrete Canvas has several advantages like easy installation, great durability, weather-resistance, and chemical-resistance. While it reduces labor cost and installation time, it, nevertheless, offers a long-lasting and sustainable solution for several containment and erosion control applications.

Benefits Over Traditional Materials

Concrete Canvas presents some interest over many traditional materials used in containment and erosion-control applications. For example, it can be laid up to ten times faster than conventional concrete systems, greatly reducing labor costs. A 2023 analysis highlighted this flexibility and bare equipment requirements as major benefits as they allow its use in remote or difficult environments.

Concrete Canvas thereby minimizes delay caused by long curing times. A comparison goes installed with just a few hours curing time after hydration in most cases, thereby reducing project delays considerably and shortening timelines. Moreover, its slim construction offers great strength by using 95% less bulk concrete type material compared to conventional methods, making it a greener option from transportation fuel consideration.

Field tests and customer case studies have reported remarkable successes. For instance, a drainage channel repair project in the UK using Concrete Canvas had its installation time cut by 50% when compared to conventional solutions, while CO2 emissions were cut by roughly 70%. Such data points towards its efficiency towards sustainable construction.

Easy to Install and Maintain

One of the key aspects of Concrete Canvas is that it offers easy installation and maintenance, ensuring that it is used frequently in a variety of civil engineering applications. Unlike traditional methods that require considerable time, machinery, and labor, Concrete Canvas can be set up in a short time with very few resources. The material itself comes in rolls that are easy to transport and lay out without heavy machinery. Once hydrated, it hardens within 24 hours and many projects complete a substantial percentage of work within that time.

Research on Google shows that installation is 10 times faster compared with conventional concrete, drastically reducing labor costs and shortening project timelines. It proves to be highly durable, requiring minimal maintenance upon installation. Numerous case studies went further to say that installations using Concrete Canvas have saved up to 60% on overall project costs due to reduced labor coupled with reduced waste. These strengths, combined with a weathering-, abrasion-resistant strong composition, make it ideal for long-term infrastructure solutions.

Versatile in Operating in Various Industries

Due to its versatility and efficiency, Concrete Canvas has had the opportunity to be the disruptive solution across industries. Accordingly, one of the dominating applications of Concrete Canvas in civil engineering involves slope protection, channel lining, and erosion control. Thanks to the simplicity of installation and robust performance, engineers have managed to use it in projects requiring rapid deployment with minimal environmental impact.

The mining industry uses Concrete Canvas as well, for slope stabilization and erosion control in high-risk areas. Its rugged composition withstands the harsh environment common with mining activities and, thus, increases the lifespan of the installation. A recent project in South Africa, for instance, demonstrated an 85% reduction in erosion when Concrete Canvas was laid on exposed surfaces around a mining site.

Concrete Canvas is also being used in the oil and gas sector for secondary containment bunds, pipeline protection, and spill control. The installation of Concrete Canvas emits up to 95% fewer carbon emissions than conventional concrete, making it truly earning its reputation as the greener alternative.

The military has also truly benefited from its versatility. Because of its rapid deployment, it is ideally suited for the construction of fortifications, field shelters, and protection barriers in very demanding operational conditions. Feedback indicates military units can create durable defenses within 24 hours, thus saving critical time in the field.

This wide variety of uses further demonstrates the flexibility of Concrete Canvas, making it a must-have solution in industries where durability, speed, and environmental compatibility are demanded.

Recent Case Studies and Examples

Concrete Canvas has been the product that really came to the rescue in a variety of situations: from fast-track military defense production to purely civil engineering solutions. This versatility combined with ease of working with and durability positions it as a tool of choice when quick deployment and guaranteed solutions are required.

Projects Successfully Completed using Concrete Canvas

- Slope Protection in South Africa

In South Africa, Concrete Canvas was employed to stabilize steeply sloping ground along a newly constructed highway. The installation covered around 10,000 square meters and was set up faster by 50% compared to conventional means, emphasizing the time-saving aspects of the process. Moreover, it was also perfect in that it curtailed the use of heavy machinery and had minimum environmental impact; in essence, a truly green and sustainable infrastructure solution.

- Channel Lining in the UK

The UK channel lining project indicated the efficiency of Concrete Canvas. The project consisted of 3 kilometers of water channel requiring erosion protection. Said cost for using Concrete Canvas was reduced by 25%, with such a period of more than 50 years hardly requiring any maintenance at all! That success story truly asserts Concrete Canvas as a long-term, durable, cost-effective solution.

- Emergency Flood Defenses in Japan

With heavy flooding as a backdrop, the deployment of Concrete Canvas for emergency flood defenses proved timely. Its rapid deployment meant that workers could shore up vulnerable areas in just days, preventing further damage to infrastructure. With the pre-hydration and simple installation requirement, the response was much faster and far more effective than traditional sandbag barricades.

Concrete Canvas sort of transformed all construction and engineering projects with the promise of a versatile, durable solution able to face most challenges.

Innovative Uses in Shelter and Containment

Concrete Canvas has played a role in providing efficient and durable solutions for shelter and containment applications around the world. Its ability to create rapidly deployable structures has been harnessed in disaster zones, warfare, and industrial applications. For example, Concrete Canvas Shelter (CCS) is an inflatable concrete-impregnated fabric structure that sets into a hardened, fireproof, and waterproof building within 24 hours of activation through water application. The shelters are particularly useful in remote and crisis-prone areas, providing alternatives to emergency tents that last far longer.

Recent statistics reveal that Concrete Canvas Shelter applications have cut setup time by as much as 70% over traditional construction methods with almost no manpower employed. The material is also impermeable to water, making it an excellent candidate for hazardous material containment and the building of robust fuel and water storage systems. Primary industries such as oil and gas, mining, and agriculture are reporting a 50% improvement in containment efficiency through the use of Concrete Canvas linings for their reservoirs, channels, and pits.

This innovation, supported by state-of-the-art material science, amounts to huge cost savings for the end user, put alongside environmental benefits (due to less carbon emitted throughout transport and installation) and really excellent longevity which amounts to at least 30 years under standard conditions. Concrete Canvas is growing its footprint and providing engineers and organizations with the latitude finish global problems with ease.

Impact on Erosion Control Effort

Concrete Canvas has become an answer for erosion control works by providing a lasting and apt solution to slope, waterway and infrastructure protection. Recent research shows that installation time can be cut down by as much as 85% when Concrete Canvas was used, in comparison with traditional concrete subjects. This implies greater savings on labor, reduced need for machinery, and owing to fewer workdays, reduced overall costs. The ability of it to conform seamlessly to the terrain also means it causes less soil disturbance on installation, making it an environmentally sound option.

Lastly, it is versatile enough to be employed in any number of contexts, including ditch lining, culvert repairs, and slope stabilization, much to showcase the strength of it. Tests showed that the Concrete Canvas lining for water management systems could endure hydraulic conductivity up to 0.01 mm/s. Its innovative nature and over 30-year lifespan combine to set a new standard in sustainable infrastructure solutions.

Future Trends and Developments

From a far-reaching perspective, I feel the immediate future for Concrete Canvas lies within advancements in its shelf life, cost-effectiveness, and environment adaptability. Continued developments may unfold an even wider array of its applications, turning it into an indispensable material across various sustainable construction and infrastructure projects worldwide.

Emerging Innovations in Concrete Canvas

Over the last few years, technical advancements in Concrete Canvas have opened the door for a wider range of applications in myriad fields. One striking example of these advancements is in the area of durability improvements. The new formulations are far better at resisting degradation caused by severe weather, UV exposure, and chemical incidences. It has been revealed by industry publications that such improvements can increase the shelf life of installations to 30% more, thus rendering them more cost-effective than before.

The manufacturing process has increasingly incorporated more sustainable measures. Studies show the production of Concrete Canvas can cut down CO₂ emissions by as much as 50% if compared to the production route of traditional concrete. This progression into a greener material therefore fits neatly with worldwide targets geared at shrinking the carbon footprint of the construction industry. It also offers logistical advantages in that it weighs approximately 8 times less than traditional concrete, so there’s less fuel consumption and energy usage in transporting and installing it.

Currently, it is also in use for disaster relief wherein, due to its properties, Concrete Canvas is fast being considered as a material for the speedy erection of emergency shelters and flood defenses. Several field studies have ratified this technology in its protecting abilities for vulnerable areas from harsh weather; one salient example being a case study where Concrete Canvas has proven very effective against floods by about 40% in reducing damages when used as a flood protective barrier.

Such developments see Concrete Canvas maintaining its stature as a global front runner in material for infrastructure solutions that are sustainable, efficient, and immensely versatile.

Potential New Applications

Concrete Canvas potentially presents very interesting applications for different industries due to its flexibility and ease of use. Some latest reports confirm its growing applications in slope reinforcement to prevent landslides, which run some $4bn annually in damages throughout the world. It has further been tested in mines where it can serve to line containment ponds to curtail water seepage and environmental contamination.

Google Trends also indicates a growing interest in the agricultural uses of Concrete Canvas, especially in arid regions. It has been demonstrated in studies how this material can be used to construct water channels and reservoirs that enhance irrigation efficiency by minimizing water loss by up to 30% when compared to traditional methods. In military applications, Concrete Canvas is currently being investigated for use in the construction of blast- and ballistic-resistant structures in a rapid manner, thus affording improved protection to personnel.

These emerging possibilities underscore the extensive possibilities Concrete Canvas has in providing innovative and sustainable solutions to current engineering challenges.

Long-term Benefits and Sustainability

Due to their immediate utility, Concrete Canvas installations expand their promise in development on the long term, especially working for sustainability and cost efficiency. Recent data suggests that Concrete Canvas installations are designed to last in excess of 120 years from proper installation and maintenance, rendering it a highly durable construction substance. The low-carbon footprint is one of the best advantages since it uses up to 95 percent less material than usual concrete solutions, which in turn reduces carbon emissions greatly.

More studies show that Concrete Canvas can conserve water use in some applications by up to 90 percent due to it being waterproof, an especially major advantage faced by regions fighting scarcity in water. On top of that, its installation efficiency earns a spotlight-the reports indicate that its deployment time rates ten times faster compared with traditional concreting techniques-witness awful savings in labor costs and project time span.

Concrete Canvas brings in great support toward circular economics: its manufacture uses low-energy production methods, and its usage helps reduce waste since its exact application only uses what can be deemed an indispensable amount of material. In anticipation of increasing market awareness on sustainable construction and constant demands for unconventional materials, Canvas Concrete is our affirmation for continuing its significant role in future projects comprising both requirements and priority for the environment.

Reference sources

1. Flexural Strengthening of RC Beams by Advanced Concrete Canvas

- Authors: Zahra Jafari, D. Mostofinejad

- Publication Date: April 1, 2024

- Citation: (Jafari & Mostofinejad, 2024, pp. 1165–1184)

- Summary: This study investigates the effectiveness of advanced concrete canvas (CC) in flexural strengthening of reinforced concrete (RC) beams. The authors conducted experimental tests to evaluate the performance of RC beams reinforced with CC under flexural loading. The results indicated significant improvements in load-carrying capacity and ductility of the beams, demonstrating the potential of CC as a viable strengthening solution.

- Methodology: The research involved preparing RC beam specimens, applying CC layers, and conducting flexural tests to assess performance metrics such as load capacity and failure modes.

2. Study on Axial Compression Performance of Corroded Reinforced Concrete Columns Strengthened by Concrete Canvas and Carbon Fiber Reinforced Plastic under Secondary Corrosion

- Authors: Fengge Li et al.

- Publication Date: March 15, 2024

- Citation: (Li et al., 2024)

- Summary: This paper explores the mechanical properties of corroded reinforced concrete columns reinforced with concrete canvas (CC) and carbon fiber reinforced plastic (CFRP). The study found that the combination of CC and CFRP significantly enhanced the axial load capacity and ductility of the columns, especially under varying corrosion conditions.

- Methodology: The authors designed and tested 42 column specimens under axial compression, varying the number of CC and CFRP layers, and analyzing the effects of corrosion rates on performance.

3. Flexural Behaviour and Strengthening of Reinforced Concrete Beams Using Concrete Canvas

- Authors: P. Sasikumar, R. Manju

- Publication Date: June 6, 2024

- Citation: (Sasikumar & Manju, 2024)

- Summary: This research examines the flexural behavior of reinforced concrete beams strengthened with concrete canvas. The findings suggest that CC can effectively enhance the flexural strength of beams, providing a lightweight and efficient alternative to traditional reinforcement methods.

- Methodology: The study involved experimental testing of beam specimens, comparing the performance of beams with and without CC reinforcement under flexural loading conditions.

Frequently Asked Questions (FAQs)

What Is Concrete Canvas and How Does It Work?

Concrete Canvas represents an unorthodox material in cement-concrete construction with a highly 3-dimensional fibre matrix containing specially formulated dry cementitious mix. Upon activation with the addition of water, rapid and efficient concrete laydown is made possible and thus is useful under a variety of conditions in erosion control and weed suppression.

What Are the Advantages of Using CC Hydro™ in Erosion Control?

CC Hydro™ has been manufactured for erosion control purposes specifically. It provides a thin, flexible, and durable layer that can be fast-layed compared to older concrete solutions. This unique application allows the solution to combat soil erosion effectively while cutting down on carbon emissions against alternatives.

How Is Concrete Canvas Used for Containment and Shelter?

Concrete Canvas is used for containment and shelter applications by forming structures that can resist harsh environmental conditions. Its concrete-filled geotextile design ensures the highest durability and stability, thus fitting for most projects requiring reliable containment options.

What Qualifies Concrete Canvas as a Cost-Effective Alternative to Traditional Concrete?

Concrete Canvas makes a highly effective program for the cost-effectiveness of conventional concrete because it is very easy to install and requires little labor. The bulk rolls can now be unrolled right onto the site, and with simple manual hand tools, workers can accomplish a great deal in a very short period.

Can Concrete Canvas Be Used for Erosion Control on Slopes?

Yes, Concrete Canvas is particularly useful for erosion control of slopes. Its specially formulated dry cementitious mix firmly adheres to different surfaces, forming a strong layer to counter soil erosion and encourage plant growth.

What Kind of Projects Do Accept Concrete Canvas USA?

Concrete Canvas USA serves such a great variety of projects: civil engineering, landscaping, environmental restoration, etc. Due to its versatility, it becomes the best of erosion control, containment, and shelter solutions across various terrains.

How Is Concrete Canvas in Comparison to Conventional Erosion Control Solutions?

Concrete Canvas is relatively fast in installation compared to the conventional erosion control method. These geosynthetic cementitious composite mats provide soil stabilization means that are both reliable and efficient, and in many cases, better than traditional methods.

What Is the Standard Specification for GCCM Materials?

The standard specification for GCCM materials specifies the parameters of performance and durability that these newly developed products should meet. Concrete Canvas and CC Hydro™ are designed according to those specifications, to ensure they deliver solutions effectively for erosion control and other potential applications.