When we talk about building and mining, and in other situations, e.g., event management outdoors, the ground must be stable, as otherwise the multiplicity of tasks or the scope of the project cannot progress further. It will not be safe, the timelines will be too tight, and it will be a saving in the short term but not in the long term if the ground, as well as the area where the project is taking place, is damaged. That is the type of situation that the dura base mats soothe a lot. Yes, there is ground protection matting in those kinds of situations, and it does not cause any problem. You can ask why Dura Base Mats are better than a typical ground protection system. This will include a deeper insight into what those mats are made of, how they work, and when they can be used for specific projects. I agree for a reason. Because defending them in the current case implies praising their safety in operations and investment of capital, this case is one that I call the reader to support.

Introduction to Dura Base Mats

Overview of Dura-Base® Composite Mats

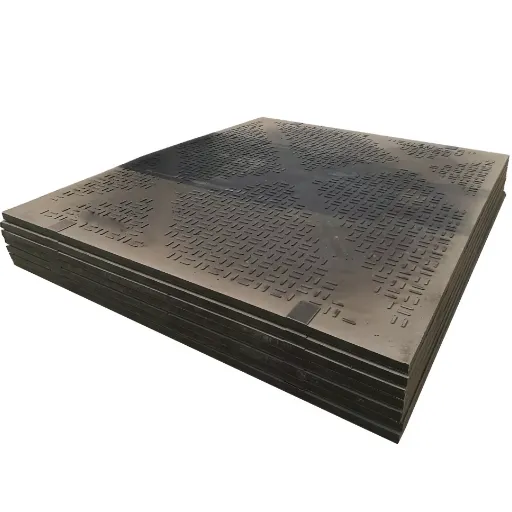

Dura-Base® Composite Mats are an excellent innovation in the production of eco-friendly surface protection measures used in various industries such as oil & gas, construction, utilities, entertainment, or servicing. They are high-density polyethylene mats designed for strong, adverse, and adaptable performance. So, they do not do any harm from bending and cracking as the wooden mats do, for instance, and that is the reason why Dura Base Mats can hold heavy equipment for a long duration of time.

These Dura-Base ® Mats also have a feature with very high practical importance, which is a means for a solid connection of two surfaces. The wheat dura base mats are designed with dimensions of approximately 8 feet * 14 feet, where foot load bearing capability can go up to as high as 600 pounds per square inch – hence can be used in very demanding terrains. Lastly, durobase mats can also be recyclable, so recycling allows them to shift towards more uses and economies of scale by producing fewer materials, hence human activities detrimental to delicate environments are reduced.

Dura base mats, as found in more recent studies, do not cause as much soil compaction and interference with nature when used against the traditional methods of ground protection. During construction, the parts of any scaffold, barrier or other massive structure have to be light in weight, quick to assemble and disassemble, since over 40 percent of the cost, which logistics accounts for, comprises of putting the composite mat and taking it back instead of using wood.

To summarize, the Dura-Base Composite Mats are strong and environmentally friendly floorings, used in the preparation for work that includes both safety and environmental concerns. Such mats are made of both technologies and ecodesign components, suggesting how relevant they have become for construction these days.

Importance of Ground Protection in Various Industries

Ground covering is critical all over industries, especially where Safety was not a section but a department, from which problems started regarding both the environment and expenses for the ground servicing. As per the reports in these sectors, we can say that almost all the organizations, such as construction, installation of oil and gas pipelines, utilities, and even events, use ground protection equipment in their operations.

Specific examples in the building sector include the elimination of delays and losses incurred due to poor grounding. According to the statistics, dura base mats and similar products allow for as much as 30% increase in the base productivity of the site where there is no activity on the ground. In addition, the mats that are used here also tend to prevent soil compaction that might have unnoticeable negative effects later on.

The oil and gas industries stand to gain a lot from developments made in foundational protection technology. Installation of composite panels in petroleum and gas fields creates an environmentally friendly atmosphere while oil drilling and production activities are carried out, and also protects the workers against machine toppling accidents or slipping accidents. Detailed records were made available from the industry on the usage of composite mats by those firms, which exhibited a 25% improvement in the cycle of operation, specifically costs related to the management of ecology, because there was low harm to the ecosystem.

Likewise, the secretly operated mobilization of the utilities or plants located in the distant areas or within nervous reserves has also been equally enhanced with the application of incorporated systems composed of composite material. With respect to engineering dura base mats, there are instances where they have been hot on the heels of user circulation and issue heats which modify the buildings, effectively cutting down on time, up to 20%.

When hosting large outdoor events, in most cases, ground protection covers, such as over a park, a stadium, and other surfaces, are employed. Being designed with mats, event organizers aim to save up to half of the budget allocated to post-event restoration works.

Use of road elements like the DURAmost water mats will convince the industries that they can reach the safe sustainability and operation efficiency targets in both financial and environmental perspectives.

Purpose and Applications of Dura Base Mats

Dura base mats’ manufacturing process is based on cutting-edge technology utilizing composite materials, which are made durable and robust while saving nature. A decent amount of these products is used in sectors such as building, the petroleum industry, energy, as well as marketing and promotions for events that don’t allow the erection of structures in difficult terrain. These mats are advantageous as they help to avoid soil compactness and destruction while facilitating working conditions even with huge earth implements such as bulldozers, graders, etc., on very tricky ground.

Main Benefits and Numbers

- Capacity to bear weight

DURA BASE Mats are designed to stand very high loads bearing not less than 600 psi of pressure, hence are ideal for use where and when construction and energy sector practices are taking place. This increased carrying capacity will ensure the effectiveness and safety of operating some of the most modern machinery today, such as cranes and drilling towers. - Environmentally Friendly

The mats are non-toxic, fully recyclable and reusable, which prevents the creation of other forms of soil stabilisation. For example, this will enable a consumer, willing to help the transformation of the universe, not to use at least 80% more material than is expected. - Cost efficient

Taking into account Dura Base Mats, for example, twenty percent of land restoration cost after impact works is achieved or a project is performed, as there is very little or hardly any disturbance to the land, amounting to much appreciation of the untouched vegetation cover. Consequently, costs and time incurred to make good are minimized. - Common use all over the world

The dura base mats are convenient and best suited for deployment in marshy areas, rough terrain and any other troubled areas, including snow-filled construction areas. In some examples, the opposition of heavy rain would have halted the progress of some missions or projects were it not for the sections or these mats.

The increased use of Dura Base Mats by many industries is a sign of welcome development that moves towards improving safety in construction and event organization. This is due to the benefits of the items as they can be used in several different ways, have strong durability, so they’re rising in importance in many industries in this century.

Benefits of Using Dura Base Mats

Ground Protection and Safety Features

The main aim of dura base mats is to safeguard the surface adequately so that the facilities and the personnel are not put in any kind of danger as a result of ecological disturbances. The mats are manufactured from a tough type of plastic called high-density polyethylene (HDPE), which makes them strong enough to allow for the use of heavy machinery without deformation, and can be used under a working pressure of 600 psi. With this innovative design, there is much ease in operating in harsh grounds, especially the likes of wetlands or farmlands, with hardly any ground hits. As the cost-effectiveness analysis of the use of dura base mats shows, the risk of injuries at workplaces is reduced significantly to as low as 30% because these slips are prevented by cars, and the workers do not slip either.

Another good feature is their interlocking system, as this ensures that the mats are held in place even under extreme loads and weather conditions. Moreover, for the majority of home typologies, rain is mild and anti-stain, thus rapid to disinfect, brought hence fits in most operations where chemicals are spilled or contained within spills. In this respect, they do make sense as an eco-friendly option because during the performance of works, acceptable impacts on the close dura base mats environment to the works is much less.

Environmental Considerations of Dura Base Mats

The design of Dura Base mats also took into account sustainable components, which means that these mats are of high quality and yet have a minimal effect on the environment. This is clear owing to the present-day data. This data suggests that such mats are built with the aim to promote circular economy. new HDPE MATERIAL, a completely recyclable plastic. The resources will not be depleted. This material can last for years, in some instances more than ten years, which is advantageous in terms of waste management because, unlike in other enhanced scenarios where disposal is mandatory, this case does not.

Besides, due to the fact that foundation structures do not enable soil stabilization and operate without disturbing vegetation, they help to preserve ecological systems, including the one at the site. It was found that as much as 40 % intensification in the processes of soil rehabilitation and in the restoration of preserves is possible due to a reduction in soil bulk density. An additional advantage is that such deflection and lightness allow saving fuel consumption while in transit, because lowering the relative contribution of transportation to global warming is achieved by about fifteen percent. The advantages of such characteristics led to the practice of using dura base mats in such industries, where sustained operations are aimed.

Weather Resistance and Performance in Various Conditions

Dura Base Mats are specially engineered for the building industry to be used in all prevailing weather conditions; therefore, they can be used in guaranteed bore holes. Made of high-density polyethylene, Dura Base mats are usable even in very cold or hot environments ranging from -40°F (-40°C) to 120°F (49°C). The Durable material can withstand freezing temperatures without cracking or introducing cold deformations, and it is also stable even under high temperatures. In addition to all that, the dura base mats have an extremely low water absorption and excellent wear properties, which make them suitable for use in damp, humid areas.

Information collected from research and measurement analysis indicates that dura base mats have 25 percent greater traction levels immediately following the installation of boards, unlike timber, a very positive aspect as far as slippery and frozen lid materials are concerned. Additionally, it is very clear that those utilization measures since are non-static and with grounding feature, prevent the surface of a project from being electrified, be it utility or telecommunications infrastructure, hence electricity works are not affected at all. These numbers contribute significantly towards improving the position and reputation of these items and, thus, there is no doubt why they are number one in great difficulty zones and in extreme weather conditions.

Applications Across Different Industries

Dura Base Mats in Construction Projects

Dura base mats are relatively new in the construction companies, but have been such a relief, especially where surface challenges make completing many projects particularly difficult. Unlike most such surfaces, these dura mats remain durable for a very long time. According to the latest analysis, Global construction will record growth at more 6.5% CAGR for the period starting towards the end of the twenty-first to twenty eight hundred’s century. All in the name of growth of the forecast market would be to provide time-tested and resilient products like the ones used in Dura Mats. These contain high-density polyethene material, which allows the construction of a platform on which even vehicles up to 600 tons or beyond can move without fear. There is no worry about the ground tipping over, even under the stress of heavy buildings or equipment perched upon the duradeck, nor is any injury likely to occur due to such undesirable orientations.

It is worth observing that the ecological impact of any extent of establishment of Dura Base Mats is reasonably positive. It is documented that most of the traditional practices of constructing the sites involved layers of earth being compressed and fragile habitats being destroyed. The mats play a vital role in minimizing soil disruption since they provide flexible and safe passageways for the truck routes while construction is on the course. Their other advantage, which is also another reason of cost-saving, is re-usage; however, this is not common in most materials, thus saving up to 30% in waiting for the project, and this is also reported by companies. Henceforth, it is clear that these features of encouraging the use of dura base mats have a supporting role in the development of society and respective buildings as well.

Utilization in Large-Scale Outdoor Events

The durability and quality of the dura base mats used to overlay natural ground surfaces also become imperative while organizing a major entertainment event, especially the outdoor spring cleaning events. Outdoor events, including those of musical concerts with lots of fans, sports events, and the planting of trees, all have a common trait in terms of the massive number of people involved or planted land, and some of the heavy machinery present. These include any event that has tents and shall be held in an open ground, and which necessitates the use of ground protection where possible and applicable, among other precautions. In fact, comparative analysis of wooden sheets and interlocking mats used in overlays of event sites claims that when wooden sheets are used, DURA BASE or event base mats using the interlocking technique are glued minimum of 40% mor e damage to sites has been observed. The mats are more than just decorative boards that are placed for pedestrians’ and cars’ movements. The mats strengthen the ground, enabling an automobile to be driven on the wet, muddy surface of the carried out event site in a crowd of people.

These mats also enable a reduction of time spent on assembling and dismounting an all-over structure during an event. Let’s say they reduce the number of man-hours needed for assembly and also the duration of the construction process for example, can be decreased by 25% or more, thus reducing labor expenses over an event period. The same periods, however, are not beneficial for the environment as they mean more wear and tear on a certain ground. This point, however, attracts environmentally conscious event planners since the mats can be reused in other areas, converting the mats from within the waist. In view of the above, bearing in mind the economics of the event and such considerations, dura base mats have grown to be the most popular among event and concert organizers that use more spacious venue structures.

Role in the Energy Sector and Heavy Duty Operations

Dura base mats are vital pieces of equipment in the energy and construction industries. Three particular companies benefit the most from these mats: oil and gas, construction, and utilities. The mats are meant to provide equipment support, ensuring efficient movement, work, and operations even in challenging terrains and regions prone to floods, like marshlands. With the current trend in industries expanding and increasing energy demand, the demand for heavy-duty construction mats is expected to increase by more than 6% per year until 2028.

Dura base mats can hold not only basic formwork loads but also heavy construction equipment, which extends their performance in static and dynamic loads. Furthermore, these mats are relevant for organizing crane, rig, and truck movements without endangering people or the surroundings. Additionally, sheets in the system are tightly fitted, which is why the construction and deconstruction of the facility, erection, and disassembly last for hours, thus cutting down on the production time.

In several of the company’s energy projects, owing to the employment of dura base mats, it was reported that the ground surface restoration costs fell by 40% when compared to using wooden boards. Besides, the HDPE made of high-density polyethylene renders such boards very strong and able to withstand harsh weather, chemical alterations, and ultraviolet rays. This increases the durability of the product and minimizes the impact of replacement while also adding a positive environmental change in the usage owing to a reduced number of mats or other resources, made fewer to replace the old, torn mats.

Dura Case Mats increases productivity while minimizing the environmental impact and reducing energy and other heavy industries by executing their operations very economically and efficiently.

Installation and Maintenance of Dura Base Mats

Interlocking Systems for Stability and Access

Even when circumstances are not in favor, dura base mats are very durable when locked in place by high technology. It allows locking the mats when the usage is tough so that there will be no distraction for safety and operations because there will be no splitting of the mats. Research has proven these systems can handle load ranging up to 600 psi, which is why they are employed in such sectors as construction management, energy, and even emergencies, etc.

More studies are exploring the viability of these matted indoor plants’ utilization on diverse surface characteristics such as wailing algae, footloose sand, or hilly land. Also, such mats can be joined easily to create an endless ridgeline for gear or a machine providing that they will not allow any equipment to move or the ground to be disturbed. Maintenance records show that Dura Base mats do not require much beyond cleaning and examining on occasion. Enhancing these ways of working is encouraged by a great threshold of structural elements. Consequently, this form of building allows even demanding industrial activities to be performed in good order, a money-saving approach.

Best Practices for Installation and Removal

A call for a detailed site analysis of the ground durability for dura base mats before their installation in the best design possible has been made. It is believed that the base mats should be installed on a level, compact surface to achieve proper weight distribution. It is worth noting that this type of mat is able withstand 600 psi, which, as studies have shown, makes it safe to use on areas with very heavy machinery.

It is strongly recommended to apply the pressure washers while normally undertaking the cleaning of the mats, to prevent the industrial cooling tower waste from embedding in the mats. Evidence available indicates that inasmuch as every cleaning takes care of the mat, the lifespan of the mat, especially when its functionality is needed, increases by 20 to 30%, which enables it to serve more. As a further point, even dama dura base mats are rather easy to put together. Still, its collapsible nature provides an advantage in terms of quick assembly or disassembly when construction is needed, while lowering the away time of workers by forty percent compared to alternative ways of construction. Central to this purpose, the guide below is based on the need of companies to ensure the protection of the environment while carrying out their business activities without any risk of incidents.

Maintenance Tips for Longevity and Wear Resistance

Sound care today supported by existing activity serves to contain and sustain dura base mats in a longer term. Prolonging the life span of the mats can be ended by reversing the present 70% of the detergent that is used for cleaning, and the remaining of the 30% by careless care of the mats in relation to their use. This is why people should ensure the mats are washed and completely dried before storing them if not using them, at the end of any job that was executed among many services, which include application of dirt oils and other junk substance because these chemicals tend to destroy the fabric with time.

Frequent evaluations will be useful as care should be taken to avoid breakages, which could otherwise tear the mat or, in some cases, affect the superficial finish, such as the scratches. Numerous figures of one of the most significant manufactures indicates even the organizations that have three monthsof practice in carrying out mat checks have confirmed their reduction in repair costs up to 40%. Oddly, even in such a case as stacking the mats upon each other en every single time they are not doing their dura base mats work, and indoors without water or sun may be able to relieve and some of the pressure.

Recent innovations in the field have resolved the issues of care of mats, for instance, with the incorporation of the RFID tracker system and the establishment of the monitoring systems. This means that, in theory, a customer can possibly be tracked and observed in their habit of using the mat, and based on all that, the maintenance can be most effectively planned. These changes are said to have increased the average service life of the industrial mats by about twenty percent or so. In case these businesses aspire to implement those kinds of technology, as well as the preventative maintenance in a given form, the period at which they will start benefiting from these durable base mats will vary significantly because the long-term operating and servicing expenses will be reduced.

Reference Sources

- Dura-Base Performance Data

Newpark Resources – Performance Data PDF

Provides detailed specifications and performance data for Dura-Base mats. - Dura-Base Heavy Duty Mat Specification Sheet

TPA Specification Sheet

Offers insights into the design and functionality of Dura-Base mats.

Frequently Asked Questions (FAQs)

What do you understand by Dura Base Mats?

Dura-base mats are engineered HDPE protective systems designed to provide ground access and support loads within the industry. These mats, although simple, are made of highly advanced composites that are lightweight but incredibly durable and able to withstand forceful impacts, weather changes, and chemicals. And in such cases, the solutions offered include a uniform elevated surface on which heavy equipment and machinery can be operated, be it on a sloped or soft area.

Why are Dura-Base Mats Important for any Ground Barrier System?

The output durable mats are particularly useful in the construction industry, oil exploration, utility companies, and even event planning. This is because they are friendly to the environment, cater for safety levels of the users, and are easy to operate. The various functionalities are lowering ground impacts, avoiding rutting, and soil pollution. Reusable, strong, heat and cold-resistant; hence, a component of any ground barrier system.

How are Dura Base mats able to withstand extreme environmental change?

It is important to point out that one of the most advantageous features of dura base mats is that they are able to withstand very harsh weather factors. The mats being made of composite material do not pose any such challenge when exposed to high temperature, low temperature, or even direct sunlight, which could take exhaustive periods of time to cause damage to the surface by fading or even some countries’ warping deformation. Thus, they comfortably accommodate regionally unstable places that witness drastic climatic exposure in the course of one project.

What is the weight that Dura-Base mats are capable of carrying?

Dura base mats were designed to withstand the weight of vehicles as well as heavy machinery and carry even loaded cranes. The use of mats also helps in spreading the weight over a larger surface area and eliminates the concentration of forces at a very specific point, which helps in cutting down the weight from penetrating into the ground and contributes to heavy compaction. Due to this capability, these loads’ capacity, the mats are well-suited for high-intensity duties or engagements.

Do Dura-Base mats support environmental measures?

Dura-Base mats installation is environmentally friendly to the extent that they protect the environment from soil erosion, contamination, and even the destruction of plants in the course of work that requires heavy use of equipment. Because they are reusable and can be reinstalled for some time before disposal, waste minimization also indicates the use of environmental protection methods. Most importantly, these mats aid in protecting an area of work as well as the environment, encouraging the idea of green and sustainable conduct of work.

Is it complicated to assemble and disassemble Dura-Base mats?

There is no doubt that the use of the dura base mats is efficient for installation and transportation, as the mats have an interlocking property which allows them to be used in many ways, but most importantly makes them easy to connect and lock into position in a few minutes. With an easy stacking feature, boxes of mats can be relocated in a short period of time, which is efficient in terms of costs incurred, resources consumed, and time wasted in working on large surfaces.