When talking sustainable solutions for erosion siltation and conservation, materials like coir and jute are the experts in green choices. […]

Geosynthetic Clay Liners (GCLs) is one of Chinas top makers and suppliers of geosynthetic clay liners. Its products used in construction and environmental work are known for being dependable and of outstanding quality. The liners impermeability, strength, and careful engineering consistently outstrip industry standards. GCL also promises smooth performance and the highest level of customer satisfaction. Count on GCL for new challenges and respected solutions tailored to your exact needs.

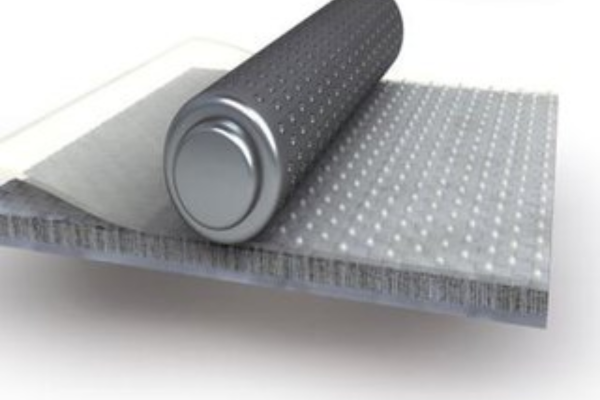

Prefabricated hydraulic barriers are clay liners consisting of a thin layer of sodium bentonite clay interposed between two layers of geotextiles. Any of the two layers can be woven or nonwoven-type textile material and can be further reinforced by geomembrane or adhesive. Since swelling of bentonite with water enhances sealing ability, the linings are intended as low-perm barriers for containment applications such as landfill liners, pond sealing, and groundwater protection.

Geosynthetic clay liners (GCLs) offer excellent impermeability with swelling sodium bentonite clay, ensuring effective sealing for landfills and ponds. Their durable design, combining bentonite with geotextiles and optional geomembranes, meets high industry standards.

Geosynthetic clay liners (GCLs) provide exceptional hydraulic barrier properties due to the swelling action of sodium bentonite clay when hydrated, effectively sealing against water and leachate migration in applications such as landfills and ponds.

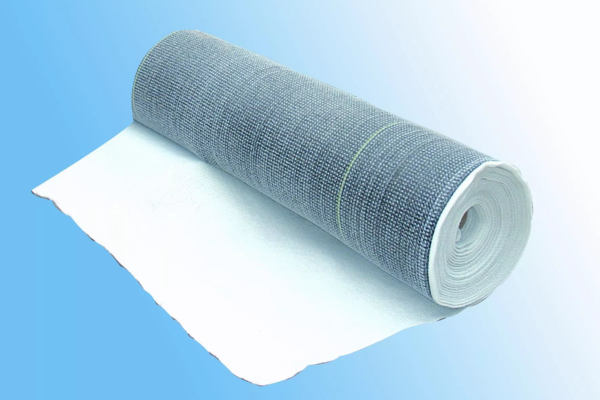

GCLs are prefabricated and delivered in large rolls, facilitating rapid and precise installation on site, which reduces labor costs and enhances project timelines in construction and environmental applications.

The combination of bentonite clay sandwiched between geotextile layers, often reinforced with geomembranes, ensures GCLs withstand mechanical stress, environmental exposure, and long-term use, exceeding industry standards for containment systems.

GCLs offer eco-friendly containment solutions by minimizing soil and groundwater contamination, supporting sustainabl

A standard needle-punched geosynthetic clay liner (GCL) features sodium bentonite clay between a woven and nonwoven geotextile, bonded by needle-punching, offering a balanced impermeability and strength for general containment like landfill liners.

This lighter variant uses less sodium bentonite clay between a woven and nonwoven geotextile, bonded by needle-punching, providing a cost-effective sealing solution for less demanding applications like decorative ponds.

With a higher amount of sodium bentonite clay between a woven and nonwoven geotextile, bonded by needle-punching, this heavier GCL offers enhanced impermeability for challenging uses like mining heap leach pads.

This GCL includes a polymeric film (e.g., polyethylene) with bentonite and geotextiles, bonded by needle-punching, adding waterproofing and chemical resistance for applications like chemical storage facilities.

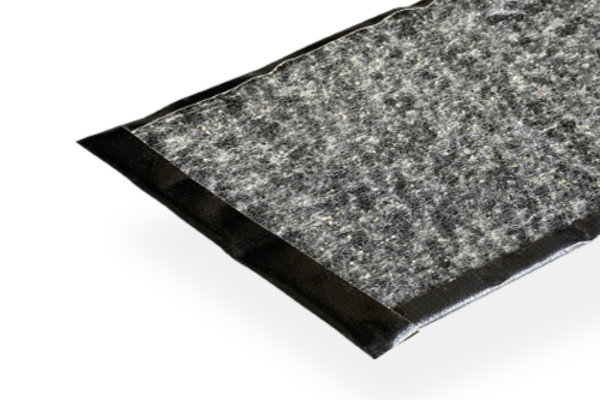

An unreinforced GCL consists of bentonite clay between two geotextiles, held by adhesives without needle-punching, suitable for low-stress uses like capping covers but less durable under heavy loads.

| Parameter Name | Example Value | Units | Notes / Description |

|---|---|---|---|

| Tensile Strength (MD / Warp) | 8 | kN/m | Ultimate Strength in Machine Direction |

| 536 | lbs/ft | ||

| Tensile Strength (CD / Weft) | 7 | kN/m | Ultimate Strength in Cross Direction |

| 469 | lbs/ft | ||

| Elongation (MD / Warp) | 10 | % | % Strain at Break in Machine Direction |

| Elongation (CD / Weft) | 12 | % | % Strain at Break in Cross Direction |

| CBR Puncture Resistance | 1500 | N | Resistance to localized puncture load (e.g., from aggregate) |

| 337 | lbs | ||

| Apparent Opening Size (AOS) | 0.2 | mm | Max particle size retained (0%) - e.g., Sieve No. 50 |

| Permittivity | 0.05 | s⁻¹ | Water flow rate perpendicular to plane |

| Mass Per Unit Area | 4000 | g/m² | Weight of the fabric |

| 132 | oz/yd² | ||

| Material Type | Bentonite with Geotextile | N/A | Materials used for the liner |

| UV Resistance (500 hrs) | 60 | % Retained | Minimum % strength retained after standard UV exposure |

| Roll Width | 4 | m | Standard roll width |

| 13.1 | ft | ||

| Roll Length | 50 | m | Standard roll length |

| 164 | ft |

Superior Waterproofing: Our geosynthetics pond liner, crafted with advanced materials, ensures exceptional water retention, preventing seepage and maintaining pond integrity over time.

Durable Construction: Designed for longevity, our geosynthetics pond liner resists punctures and environmental degradation, offering a reliable solution for diverse pond applications.

Expert Manufacturing: Produced by leading geosynthetic clay liner manufacturers, our liners adhere to stringent quality standards, ensuring consistent performance and customer satisfaction.

Easy Installation: The geosynthetics pond liner is supplied in convenient rolls, facilitating straightforward installation and reducing labor costs for pond construction projects.

Environmental Compatibility: Our liner supports eco-friendly water management, aligning with sustainable practices and minimizing ecological impact, as endorsed by geosynthetic clay liner manufacturers.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

A geosynthetic clay liner (GCL) is used for containment applications, including landfill liners, pond and lake linings, mining heap leach pads, and canal or reservoir waterproofing, to prevent water and leachate migration.

The thickness of a geosynthetic clay liner typically ranges from 5 to 10 mm, depending on the specific design and the number of geotextile or geomembrane layers incorporated.

Geosynthetic lining refers to a broad category of synthetic materials, such as geotextiles, geomembranes, and geosynthetic clay liners, used to provide impermeable or reinforced barriers in civil engineering projects for containment, drainage, or erosion control.

The different types of clay liners include compacted clay liners (CCL), geosynthetic clay liners (GCL) with needle-punched or unreinforced designs, and composite clay liners combining clay with geomembranes, each tailored to specific containment needs.

For landfill covers, the needle-punched GCL with integrated polymeric film is often used, as it provides enhanced waterproofing, chemical resistance, and durability to protect against environmental exposure and leachate.

A geosynthetic clay liner functions as a low-permeability barrier, utilizing the swelling properties of sodium bentonite clay to seal against water and contaminants, while the geotextile layers add structural support for applications like waste containment and water management.

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

When talking sustainable solutions for erosion siltation and conservation, materials like coir and jute are the experts in green choices. […]

Weeds, gardeners and landscapers’ constant trouble, not only take over the outdoor space but also depril the plants of the […]

The use of geosynthetics is indispensable in the modern era of engineering and construction, as they provide ingenious ways to […]

The trees’ health and longevity depend on the care given, and this includes trees found in the backyard or a […]

When the ground is difficult to work with due to construction, changes in land use, or heavy outdoor events, practicing […]

When it comes to safeguarding our environment and managing vital water resources, geomembranes play a pivotal role behind the scenes. […]

The construction industry, agricultural sector, and environmental projects use PVC geomembrane liners because these materials provide both long-lasting waterproofing solutions […]

The very first consideration when talking about the protection of water storage facilities is by which materials the whole thing […]

Enhance your containment solutions with high-performance geosynthetic clay liners (GCLs), designed for landfills, mining, ponds, and water management. Leveraging advanced technology, these eco-friendly liners offer superior sealing, durability, and ease of installation, meeting stringent environmental regulations. Contact us today to secure a competitive geosynthetic clay liner price tailored to your needs, and discover how our cost-effective solutions can elevate your project’s efficiency and sustainability. Act now to request your personalized quote!

A: A geosynthetic clay liner (GCL) is made of a layer of sodium bentonite clay encapsulated between two geotextile layers, which may be woven or nonwoven, and sometimes reinforced with a geomembrane or adhesive for added strength.

A: Geosynthetic clay liners are commonly applied in landfills, pond linings, mining heap leach pads, canal waterproofing, and reservoir containment to prevent water and leachate migration.

A: A geosynthetic clay liner achieves impermeability through the swelling action of sodium bentonite clay when hydrated, which fills voids and creates a tight seal, enhanced by the supporting geotextile layers.

A: The typical lifespan of a geosynthetic clay liner ranges from 30 to 50 years, depending on environmental conditions, installation quality, and maintenance, with some applications lasting longer under optimal conditions.

A: Yes, geosynthetic clay liners can be used in cold climates, as they remain flexible and effective when properly installed, though precautions such as insulation or protective cover layers may be required to prevent freezing damage.

A: Installation requires a smooth, compacted subgrade free of sharp objects, careful unrolling of GCL rolls with overlapped seams (150–300 mm), and secure seaming and anchoring to ensure a continuous barrier.

A: Geosynthetic clay liners offer thinner profiles (5–10 mm) and easier installation compared to compacted clay liners (300–600 mm), while providing similar impermeability with the added benefit of geotextile reinforcement.

A: Yes, geosynthetic clay liners are environmentally friendly, as they use natural bentonite clay and synthetic materials to minimize soil and groundwater contamination, supporting sustainable waste and water management practices.