The significance of stormwater filtration in urban water quality management and environmental protection cannot be overemphasized. With urban centers growing […]

One of many manufacturers and suppliers of PVC geomembranes in the country, PVC Geomembranes offers reliable and highest-quality products for the industrial construction and environmental sectors. The flexibility, durability, and workmanship of PVC Geomembranes that surpasses standards in the industry. PVC Geomembranes guarantees operational efficiency together with complete customer satisfaction. You can trust PVC Geomembranes with ever-shifting applications and renown solutions for precisely set preferences and needs.

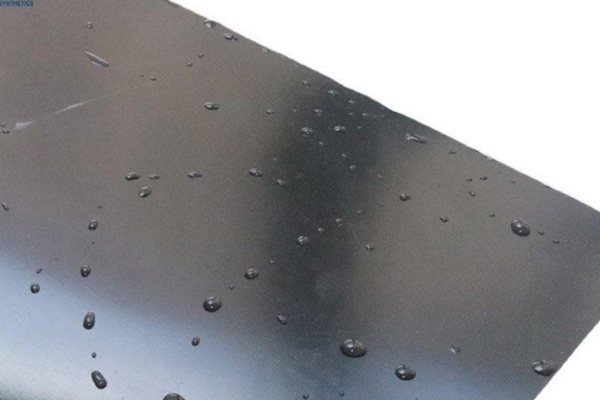

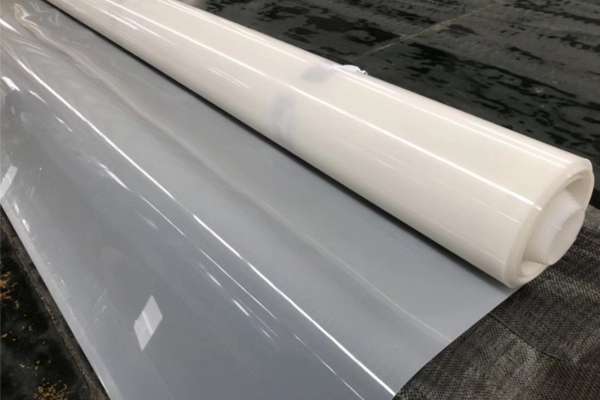

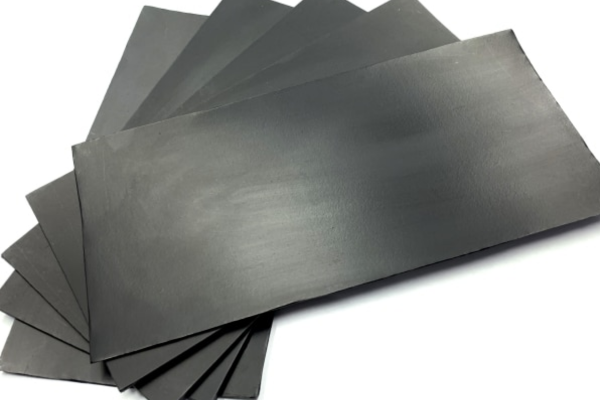

PVC geomembrane refers to liners made from polyvinyl chloride (PVC), a flexible and durable synthetic material. A geomembrane PVC serves as an impermeable barrier to prevent the seepage of liquids or gases, while a PVC geomembrane sheet is widely used in applications such as ponds, landfills, and tunnels, offering reliable containment and chemical resistance.

PVC geomembranes shine with their remarkable flexibility, robust chemical resistance, watertight seam integrity, and cost-effective durability, making them a dynamic choice for diverse projects!

PVC geomembranes exhibit excellent flexibility, enabling easy installation and conformity to irregular surfaces.

They provide robust resistance to a variety of chemicals, ensuring reliable performance in diverse environments.

PVC geomembranes offer strong, watertight seams through heat welding, enhancing overall containment effectiveness.

These geomembranes deliver durable performance at a competitive price, making them an economical choice for many projects.

Ideal for light to medium stabilization, this fabric provides a grab tensile strength of 150 lbs, perfect for soil separation and basic erosion control on driveways and pathways.

With a 200 lbs grab tensile strength, this versatile fabric excels in road stabilization, aggregate separation, and light construction projects, ensuring long-lasting performance.

Offering a robust 250 lbs grab tensile strength, this option is suited for unpaved roads, rip-rap support, and areas requiring enhanced stabilization under heavier loads.

Our strongest fabric with a 315 lbs grab tensile strength, ideal for demanding road construction, embankment support, and heavy-duty erosion control projects.

Designed for extreme stabilization, this high-strength fabric offers a 350 lbs grab tensile strength, perfect for industrial containment, large embankments, and critical infrastructure projects.

| Parameter Name | Example Value | Units | Notes / Description |

|---|---|---|---|

| Tensile Strength (MD / Warp) | 80 | kN/m | Ultimate Strength in Machine Direction |

| 5360 | lbs/ft | ||

| Tensile Strength (CD / Weft) | 75 | kN/m | Ultimate Strength in Cross Direction |

| 5025 | lbs/ft | ||

| Elongation (MD / Warp) | 20 | % | % Strain at Break in Machine Direction |

| Elongation (CD / Weft) | 22 | % | % Strain at Break in Cross Direction |

| CBR Puncture Resistance | 2500 | N | Resistance to localized puncture load (e.g., from aggregate) |

| 562 | lbs | ||

| Apparent Opening Size (AOS) | 0.25 | mm | Max particle size retained (0%) - e.g., Sieve No. 50 |

| Permittivity | 0.2 | s⁻¹ | Water flow rate perpendicular to plane |

| Mass Per Unit Area | 200 | g/m2 | Weight of the fabric |

| 5.9 | oz/yd2 | ||

| Material Type | PVC | N/A | Polymer used for the fabric |

| UV Resistance (500 hrs) | 65 | % Retained | Minimum % strength retained after standard UV exposure |

| Roll Width | 4 | m | Standard roll width |

| 13.1 | ft | ||

| Roll Length | 100 | m | Standard roll length |

| 328 | ft |

Exceptional Flexibility: Our PVC Geomembrane offers superior flexibility, ideal for complex project shapes and installations.

High UV Resistance: Engineered to withstand prolonged sun exposure, ensuring long-term durability

Reliable Waterproofing: Provides a robust, leak-proof barrier for landfills and ponds, enhancing containment efficiency.

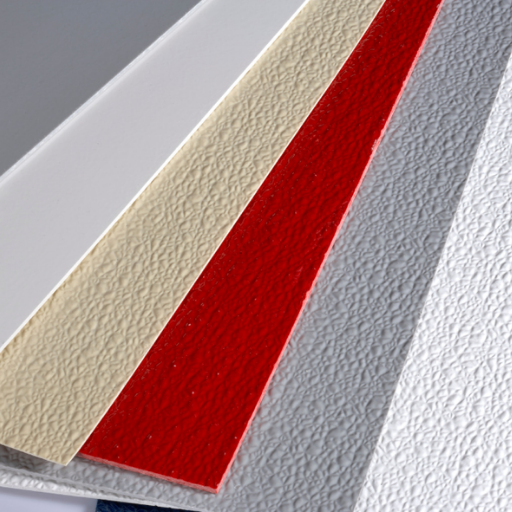

Customizable Options: Tailored thicknesses and sizes meet specific project needs with precision.

Proven Quality: Manufactured under strict standards, our PVC Geomembrane exceeds industry performance expectations.

Understand from our clients what they say about doing business with us and the unique value addition we provide.

PVC geomembrane is used as an impermeable liner for ponds, landfills, and canals, preventing water and leachate seepage in civil and environmental projects.

PVC geomembrane is more flexible and UV-resistant, ideal for ponds, while HDPE geomembrane offers higher chemical resistance and strength for landfills and mining.

PVC geomembrane serves as a waterproof barrier in aquaculture ponds, wastewater treatment, and roofing, ensuring containment and protection.

PVC is better for cost-effective, flexible pond lining, while EPDM excels in UV resistance and longevity for decorative ponds.

Yes, PVC is widely used as a pond liner due to its flexibility, waterproofing, and suitability for various water features.

A 30 mil PVC liner is 0.75 mm thick, offering a balance of durability and flexibility for moderate pond applications.

A PVC pond liner should be 20-40 mil (0.5-1.0 mm) thick for small ponds, or 60 mil (1.5 mm) for larger, deeper ones.

A PVC pond liner typically lasts 10-20 years, depending on UV exposure, water quality, and maintenance

Seal a PVC pond liner by overlapping seams, welding with a hot air gun or solvent, and securing edges with anchors or soil to prevent leaks.

Maintain Inventiveness by Following The Blog for the Latest Best Practices, Techniques, Innovations, and Insights in the Field.

The significance of stormwater filtration in urban water quality management and environmental protection cannot be overemphasized. With urban centers growing […]

To create a stunning and practical pond, meticulous planning is needed, with one of the most important decisions being the […]

PVC geomembrane liners have the best overall performance in durability and reliability, which is why they are highly regarded by […]

The correct installation of geomembrane liner is a decisive action that guarantees the performance and durability of the containment system […]

An essential feature of modern infrastructure design is stormwater management in response to urbanization and its associated challenges arising from […]

Mechanically Stabilized Earth (MSE) retaining walls represent a major upgrade in the world of modern construction and infrastructure. These innovative […]

It’s an obvious fact that heavy-duty composite mats have come in handy where there is a need to protect sensitive […]

Among the solutions for environmental containment that exhibit both longevity and efficiency, one of the most versatile is the geomembranes […]

With customizable thicknesses ranging from 20 mil to 80 mil, our PVC Geomembranes meet stringent industry standards, offering cost-effective, fish-friendly, and oil-resistant options. Benefit from our expertise in tailored solutions, supported by over 40 years of safe clinical use data, ensuring environmental safety and operational efficiency. Contact us now to get PVC Geomembrane prices.

A: PVC Geomembrane is made from polyvinyl chloride (PVC) with plasticizers, stabilizers, and UV-resistant additives, ensuring flexibility and durability.

A: PVC Geomembrane is used for pond liners, landfill caps, canal waterproofing, and wastewater treatment, providing effective containment.

A: PVC Geomembrane offers greater flexibility and UV resistance, while HDPE provides superior chemical resistance and tensile strength.

A:Yes, PVC Geomembrane is fish-friendly and widely used for ponds, provided it meets safety standards for water quality.

A: PVC Geomembrane comes in thicknesses from 20 mil (0.5 mm) to 80 mil (2.0 mm), tailored to project needs.

A: PVC Geomembrane typically lasts 10-20 years, depending on UV exposure, maintenance, and environmental conditions.

A:Yes, PVC Geomembrane can be customized in size, color, and thickness to meet specific project requirements and design preferences.

A: Install by preparing a smooth surface, unrolling the geomembrane, welding seams with a hot air gun, and anchoring edges with soil or weights.