When speaking of normal methods of pond lining, the classic way falls behind, usually trapped in a trade-off between effectiveness and efficiency related to durability, safety, environmental concerns, and so on. Witness an engineering creation-that-a-modern approach-that-marries-a-natural-with-a-synthetic-component: GCLs truly offer something extra in pond sealing. Depending on the interest in water retention for agricultural purposes, industrial applications, or an environmental protective cause, one would need to study the benefits and applications of GCLs. In this article, all there is to know about GCLs will be examined, from their unique composition to the benefits they offer over conventional solutions, thus making them a possibility for your next project. I would urge you to keep reading, as you will learn why GCLs stand fast in remembrance as the buddy across industries for converting ponds!

Introduction to Geosynthetic Clay Liner

Geosynthetic Clay Liners (GCLs) are composite materials used primarily for waterproofing and containing liquids. A layer of natural bentonite clay is sandwiched between geotextiles or adhered to a geomembrane. When the bentonite swells upon hydration, it creates a highly sealant barrier against water and other fluids. They are considered a reliable and cost-effective waterproofing material that also benefits from easy installation and can act as a substitute for conventional compacted clay liners in numerous applications.

What Are Geosynthetic Clay Liners?

Geosynthetic clay liners (GCLs) are very sophisticated composite materials widely applied in civil and environmental engineering for containment and lining. They are thin sheets of sodium bentonite clay sandwiched between two or more layers of geotextiles or bonded to a geomembrane. The bentonite clay is renowned for its swelling property, which enables the GCL to form one of the most effective self-sealing barriers upon hydration.

GCLs are used for an array of projects including landfill liners, mining containment systems, wastewater treatment facilities, and pond construction. It has been forecasted that the total global Geosynthetic Clay Liners market will grow at a compound annual growth rate (CAGR) of around 6.5% in the forecast period from 2023 to 2030, following increased demand for sustainable and cost-efficient materials geared toward infrastructural development and environmental protection projects.

Installation procedures have been a major issue that distinguishes GCLs from the traditional compacted clay liners. Installation of GCLs under normal circumstances requires far fewer materials and less labor compared to the thickness of compacted clay liners-a 3-foot thick compacted clay liner to be precise. The inherent qualities of GCL also make them adaptive to changing site conditions and hence adaptable to construction under difficult environmental conditions. Laboratory test results indicate hydraulic conductivity of GCLs in the range of 1×10⁻⁹ and 1×10⁻¹¹ m/s, indicating excellent capability to resist fluid percolation.

Therefore, the synthesis of performance, cost, and environmental sustainability has made Geosynthetic Clay Liners the first choice in various containment applications all over the world.

Composition of GCLs

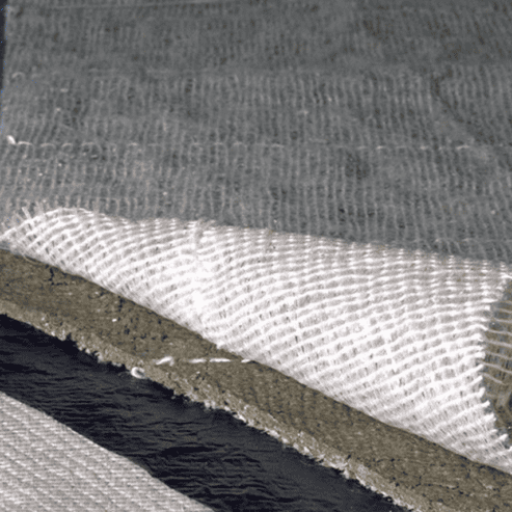

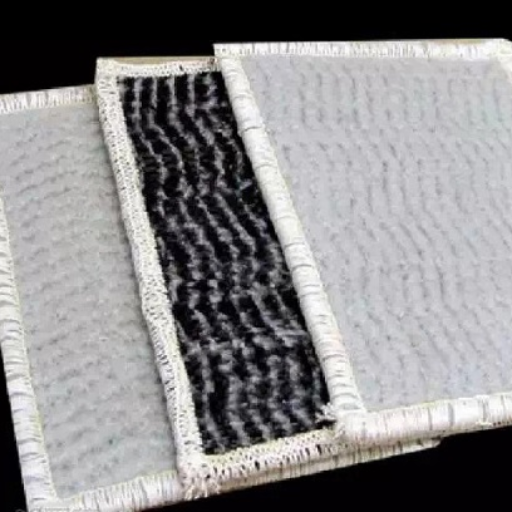

Geosynthetic Clay Liners, more simply called GCLs, are made up of three major components that together provide an effective barrier layer for containment:

Geotextiles: GCLs are usually reinforced by two layers of geotextiles, usually non-woven or a combination of woven and non-woven fabrics. These layers serve to provide strength, durability, and protection for the bentonite clay core from mechanical damage.

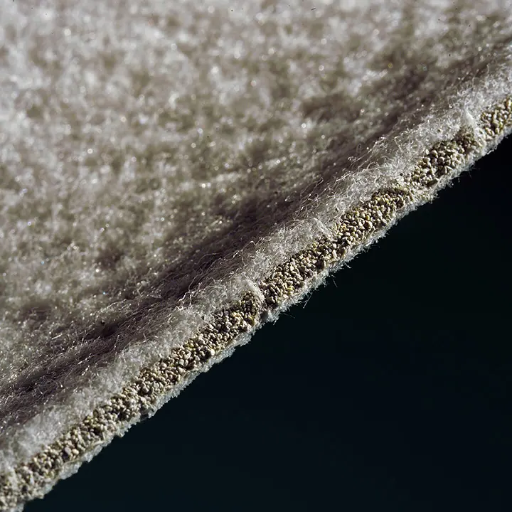

Bentonite Clay Core: The primarily working member of GCLs consists of sodium bentonite clay, which is a natural, highly absorbent material. Once hydrated, sodium bentonite swells so much that it forms a low permeability gel layer capable of sealing leaks of liquids and gases. The hydraulic conductivity of hydrated sodium bentonite can be as low as 1×10⁻¹⁰ m/s, depending, however, on factors such as the degree of confinement and quality of hydration.

Carrier Layer (Optional): Some variations of GCL comprise a carrier layer such as a geomembrane for enhancing the sealing and impermeability to resist environmental degradation.

Laboratory studies show that GCLs with sodium bentonite perform well in various applications, with results reporting an average swell index of 24 mL/2g and a fluid loss value of less than 15 mL as per ASTM D5890 and D5891 test standards. The tensile strength of the geosynthetic layers usually exceeds 400 N depending on the design of the material, thus offering mechanical stability under different operational stresses.

When well-engineered, GCL components, in conjunction with each other, come out to be a versatile and reliable solution to environmental problems in landfill liners, mining applications, water containment systems, and so on.

Main Applications by Construction and Environmental Projects

GCLs have become a backbone in construction and environmental engineering projects by virtue of their superior containment ability and design versatility. Below are some fields where GCLs find their use underpinned by recent technological advances and gathered data:

Landfill Liners and Caps

The GCL finds its largest application in landfill constructions as a barrier for waste containment. They are often used as single liners or in combination with geomembranes to form composite liner systems, GCLs. According to literature, the hydraulic conductivity of GCLs generally ranges from 1×10⁻⁹ m/s to 5×10⁻¹⁰ m/s, with minimal leakage rates, making it very effective in preventing leachate migration from contaminating the soil and groundwater.

Mining Industry Application

GCLs frequently come into application in mining activities: tailings storage, heaps of leach pads, and wastewater ponds, as viewed with excellent tensile strength above 400N capable of maintaining stability even under high stress and loads. Further recent development features polymer-enhanced GCL capable of resisting aggressive chemical exposure, thereby extending its application in mining wastewater management.

Water Containment Systems

GCLs are already getting preference for lining reservoirs, canals, and agricultural ponds due to their superior impermeability and ease of installation. GCLs require less time and material for installation compared to conventional compacted clay liners, thereby saving project costs by up to 50% without reduction in performance. Its swell index of 24 ml/2g ensures good hydration, providing reliable sealing even with the fluctuations in water level.

Infrastructure Projects

GCLs proved their adaptability for use under various civil engineering projects, including roadways, tunnels, and railways. In roadworks application, for example, it is used to reduce water infiltration and the subsequent softening of the subgrade. In the newly released case studies, it has also been demonstrated that GCLs reduce civil maintenance expenses and expansion by 20% over time.

Environmental Protection Initiatives

With an ever-growing propensity toward sustainability, GCLs play a pivotal role in efforts to conserve ecosystems. They are used in wetland restoration and flood control systems to minimize environmental impact while facilitating water management. Furthermore, their lightweight nature also edges down on carbon emission related to transportation and installation.

Overall, the ease of adaptability and superior performance characteristics place GCLs as the engineer’s first line of solution in handling both technical and environmental issues.

Advantages of GCLs

Some of the key benefits of using GCLs are excellent hydraulic performance, cost-effectiveness in comparison with traditional liners, and environmental compatibility. A GCL can adapt to many different applications, and installation is straightforward. Hence, GCLs remain the standard option for any project that requires a dependable yet green solution.

Cost-Effectiveness of GCLs

Geosynthetic clay liners (GCL) stand out with their economic benefits over traditional compacted clay liners (CCL). Traditional industry data estimates management costs will decrease by approximately half when GCLs are used because of decreased volume of materials for any particular project and ease of transportation with respect to compacted clay liners. Yet, in addition to lower transportation costs, heavy machinery needed for installation is less, or even in some cases unnecessary, thereby allowing further reduction in installation costs, especially for terrains difficult to access with heavy machinery or for sites with space limitations.

GCLs need ordinarily only 5 to 10 mm in thickness to yield the intended low hydraulic conductivity compared to CCLs that need layers of often 600 mm thick. Lesser materials reduce price and save precious natural resources. Moreover, being pre-assembled and lightweight GCLs are very helpful in fast installations and provide for reduced project duration and lessening of labor cost. These factors make GCLs an extremely economical alternative to traditional compacted clay liners that can save the needed budget without compromising performance or durability.

Installation Compared to Compacted Clay Liners

Geosynthetic Clay Liners (GCLs) offer a much simpler and quicker installation process than traditional Compacted Clay Liner (CCL). Research shows that methods are faster by 50% to 70% when employing GCLs since they are engineered in factories as prefabricated liners. Although CCL installations require a fully prepared subgrade and repeated cycles of clay placement and compaction optimized with moisture control, GCLs can be installed upon delivery with minimal or no site preparation effort. This decrease in installation complexity also causes reductions in utilization of heavy equipment and skilled labor, thereby reducing total installation costs by up to approximately 30%.

Besides, GCLs adapt well to variable and irregular site conditions. They can conform easily to uneven or rough terrains to ensure integrity of coverage without intensive grading or preparation. It is reported that in using GCLs in large projects, material transport and labor have been cut about 40%, thus saving money and contributing to a low carbon footprint.

By drastically reducing the complexities accompanying installation, GCLs ease the process of project execution while at the same time being recommended as an environmentally friendly and cost-efficient substitute to traditional compacted clay solutions.

Environmental Impact of GCLs

Geosynthetic clay liners (GCL) have been claimed to exhibit a series of environmentally friendly properties; thus, being preferred in some containment and landfill capping projects. The latest research and data evidence highlight their role in carbon footprint reduction in construction activity. According to a study, the making and transport of GCLs involve much fewer raw materials as compared with those for the traditional clay liner. The requirements in terms of materials for making GCLs may also fall short by as much as 90% of those for compacted clay layers, meaning huge carbon emissions reductions from quarrying, transport, and installation activities.

Besides, GCLs improve containment efficiency in lowering unintended leakage of hazardous substances into leachate. Low hydraulic conductivity (typically < 5×10^-12 m/s) guarantees protection for long-term subsurface water from contamination. Another landfill application case study shows that GCLs reduce leakage rates by more than 50% when compared to conventional barriers. Further, polymer-modified GCLs’ enhancement has made them more chemically resistant, thereby extending their lifespan and ensuring they are acceptable in pernicious working conditions.

Those developments place GCLs at the core of achieving sustainable construction while maintaining existing stringent levels of environmental protection.

Advances in GCL Technology

I believe that an improvement in GCLs after polymer modification has greatly contributed toward reducing leakage rates and enhancing chemical degradation resistance. Designs ensuring the safe use of GCLs under harsh conditions have been developed, making GCLs an environmentally safe or green product.

Recent Developments in Geosynthetic Clay Liners

Recent developments in geosynthetic clay liners have emphasized some critical improvements in their design and use, thereby enhancing their applicability across modern engineering works. These advancements mostly center on the rise in use of polymer-enhanced bentonite to increase resistance of liners to chemical contaminants and to reduce permeability. According to a 2023 article, polymer-modified GCLs displayed up to a 50% reduction in hydraulic conductivity against traditional GCLs in aggressive chemical environments.

Besides these, modern methods have promoted multi-layer configurations where a GCL would be coupled with a geomembrane. This further improves the performance of the overall system by adding additional barrier layers shielded against fluid migration, thereby presenting an ideal candidate for applications like landfill capping and wastewater treatment facilities. Industry sources state this combination may realize a 70% reduction in leakage rates when compared with GCLs used alone.

Another advancement is in the form of incorporation of self-healing materials that permit GCLs to reseal relatively minor perforations and tears autonomously, thereby guaranteeing longevity. Field testing conducted on recent projects found that self-healing GCL systems reduced maintenance costs by almost 30%, thus delivering both economic and environmental benefits.

These further developments show growing prominence being given to using novel materials and designs in meeting newer demands of environmentally-friendly construction procedures.

Superlative Performance for Landfill and Mining Applications

Integration of advanced geosynthetic clay liners (GCLs) has improved somewhat the containment systems’ performance in landfill and mining applications. These materials are endowed with excellent impermeability, thus preventing hazards from leachate and pollutants contaminating the surrounding soil and groundwater. Research has shown that modern GCLs have hydraulic conductivity rates as low as 5×10⁻¹² m/s, which assuredly provide containment under both high pressure and adverse environmental conditions.

Additionally, GCLs have self-healing properties that further refine their functioning in the industries under analysis. In landfills, GCLs mitigated the differential settlement while maintaining the seal effectiveness, decreasing the possibility of leakage. More recent case studies evidence that GCLs can increase sealing efficiency, by up to 40%, compared with classic clay liners in mining tailing storage facilities (TSFs), giving better resilience under chemical and mechanical transforms.

Moreover, the costs in which GCLs are used may lead to cost savings. They lower construction costs, drastically, by reducing the requirement for natural clay needed in containment systems. The study of a mining project in Australia revealed that the installation costs have been reduced by more than 25%, while the overall time for project completion was shortened by 20% during the use of GCLs in combination with geomembranes.

Such enhancements greatly serve sustainable construction while remaining compliant with environmental legislation. Progression in GCL technology allows landfill and mining operations to achieve safer, more reliable, and cost-effective containment solutions, further solidifying their prominence in modern environmental engineering.

Technological Advancements for Steeper Slopes

The Geosynthetic Clay Liner (GCL) has gone through many improvements in recent years, enabling its wet application on steeper slopes over landfill and mining sites. Recent information shows that innovations in polymer coatings and adhesive reinforcement have increased the shear strength performance of GCL systems, thus improving slope stability for slopes exceeding 3H:1V. Composite liner systems also show similar improvements in tensile strength, where increases of up to 25% have greatly reduced the risk of shear failure even at high loads.

Furthermore, a combination of moisture barriers and composite fabrics has been integrated into the latest generation of GCLs. The combination provides for continuous hydration of the bentonite layers, helping them to perform optimally over the long term. An environmental engineering survey study concluded that slopes constructed with these technologies showed a 30% reduction in leakage rates when compared to traditional counterparts. These data thus confirm the ever-increasing reliability and versatility of GCLs in challenging slope systems, making them a must-have in all modern-day containment systems.

Regulatory Standards and Guidelines for GCLs

Geosynthetic Clay Liners do not have the same set of uniform standards internationally. On the contrary, the regulations usually focus on minimum performance requirements for the protection of the environment. The requirements normally have limits on the hydraulic conductivity, thickness, and durability of the device. In the United States, the Environmental Protection Agency (EPA) demands that GCLs meet permeability criteria to prevent the migration of fluids and ensure the integrity of containment. Other major considerations are material testing for chemical resistance and stability for long-term applications under environmental stresses. For precise regulations, refer to guidelines in the specific region or look into ASTM D5887 for permeability testing or ISO standards for geosynthetic materials.

An Outline of the Regulations with Which to Comply

A split fold of submission between an international, national, and regional law system serves to govern GCLs for their reliability and environmental safety. The United States Environmental Protection Agency (EPA) prescribes under the Resource Conservation and Recovery Act (RCRA) specific guidelines for the use of GCLs in a waste containment system in landfill projects. Importantly, Subtitle D of RCRA requires GCLs placed in landfill liners to be held to extremely low permeability limits, generally requiring that hydraulic conductivity be 1×10-Z m/s or less to prevent the migration of leachates.

At the international level, both ASTM and ISO organizations have produced their own sets of standards to test and verify GCL properties: ASTM Standards, such as ASTM D5887, for hydraulic conductivity of GCLs under chemical solutions, while ISO 10318 defines and classifies geosynthetics so that they can be aligned in the global regulatory sense.

The Landfill Directive (1999/31/EC) by the European Union followed suit, enforcing a similar level of scrutiny for lining systems with an accent on environmental monitoring and prevention of leakage. Other exciting data from industry research are hinting at a progression, such as polymer-modified GCLs that should provide enhanced chemical resistance and performance under severe conditions-which matches well with the tighter restrictions in modern regulations.

For engineers and project designers, ongoing compliance obviously means keeping up with new developments on the material side and regulations side so that the entire system may meet those developments ahead while simultaneously tackling present demands of environmental concern.

Compliance and Best Practices for GCL Installation

Compliance and best practices in the installation of geosynthetic clay liners (GCLs) directly relate to long-time performance and the maintenance of environmental safety standards. Present legislation, such as the EPA and ISO 10318-1, stresses proper installation to optimize GCL functioning and eliminate any leakage or contamination risk to the environment.

- Quality Control and Handling of Materials:

Compliance requires special attention toward the handling of materials while in delivery and in-site storage. Always store GCL rolls in a clean and dry area, with protection against moisture, UV exposure, or mechanical harm. Research points to degradation in hydraulic conductivity from improper storage, causing unwanted effects on the material’s integrity.

- Subgrade Preparation:

Smooth is the word describing subgrade preparation required for perfect GCL behavior. It should be free of any objects with sharp edges and be packed well to avoid damaging the liner. New data from the field reveals around a 20% possibility of hydraulic failure due to unnoticed irregularities on the subgrade. Best practice is to go for a strict inspection protocol plus application of protective underlayments, if needed.

- Overlapping and Seaming Methods:

Maintaining a consistent overlap while installing GCLs is essential to preserving the integrity of the system. Industry recommendations are for an overlap of no less than 6 inches (15 cm) for adjacent panels to avoid any pathways for leakage. For steep slope applications, new research on slope stability found that self-seaming adhesives or polymer-enhanced edge bonding are effective in reducing slippage.

- Hydration Before Backfilling:

Hydration is more or less the essential treatment after placement to get bentonite to swell actually before it gets stressed much by overburden. Studies have indicated that the loading of GCLs in a dry state much earlier may drop liner performance by 50% as a result of uneven swelling and development of stress cracks.

- Installation Documentation and Reporting:

All completed documentation on site testing, material inspections, and actual installation conditions are legally binding for compliance. Progress in new software report/application tools has, in fact, offered for monitoring and logging data in real time, which guarantees 100% traceability and adherence to project specifications.

These best practices and the technological advancements researched and supported by the industry will allow engineering and project teams to guarantee that GCL systems perform as expected through long-term compliance while providing strong environmental shelter for many decades.

Case Studies on Regulatory Success with GCLs

Improved Regulatory Compliance in Landfill Applications

The most important regulatory success was realized as a consequence of landfill construction, where GCLs have assisted in consistently meeting severe environmental requirements. This is because the permeability of GCLs lies at the levels of 5×10⁻¹¹ m/s, well below the accepted levels required by the standards concerning barriers to contaminants. They extraordinarily lower the probability of groundwater contamination, thus becoming the preferred choice.

Mining Industry Use of GCLs

GCL systems are gaining popularity for waste containment solutions within the mining industry. A case was made in Chile for tailings storage facilities where GCLs have reduced seepage rates by 90 percent relative to that given by classical clay liners, providing assurance of compliance with local and wider environmental standards, with less risk posed to surrounding ecosystems.

Cost-Effective Solutions to Infrastructure Projects

Construction projects requiring low permeability barriers are also great beneficiaries of GCL technology. For instance, in highway construction, GCLs were installed to protect nearby wetlands from runoff generated along the highways in the United States. The use of GCLs allowed the project team to reduce costs by roughly 40% compared to compacted clay liners without jeopardizing regulatory compliance.

Key Takeaway

These case studies confirm that the adaptability and reliability of GCLs make them an invaluable tool for industries aiming to meet or exceed environmental regulations. Supported by real-world applications and documented success, GCLs provide an evidenced path towards achieving long-term environmental sustainability.

Expert Opinions on GCLs

Given their versatility, reliability, and cost-efficiency, their applications in environmental regulations must be evidence of their excellent performance. Hence, considering real-world applications, I see them as a sustainable option that goes hand in hand with compliance, making them great for several industries.

Industry Experts’ Perspectives

Geosynthetic Clay Liners have achieved worldwide recognition for their worthy performance in environmental engineering and waste containment purposes. The latest data from industry presenters have shown increasing use of GCLs in landfill caps, MSW landfills, and mining applications due primarily to their ability to reduce seepage and prevent groundwater contamination.

Studies also report that a GCL practically has hydraulic conductivity that may reach the order of 1×10⁻¹¹ m/s, which comes very close to what is expected from an ideal barrier for contaminants, almost always better than any CCLs. While installation is easier for them because they are thin compared to CCLs, also quite advantageous is the reduction of transport charges and a material cost reduction averaging 50-70% for many projects. These factors position GCLs as a preferential choice whenever infrastructure projects seek to establish a balance between environmental consciousness and operational ease.

Alongside GCL developments, recent innovations have further improved their functioning. The latest modifications of polymeric bentonite provide better resistance against chemical degradation, which has improved the use of GCLs in the containment of hazardous wastes. Economic viability, combined with longevity, pushes GCLs into a prominent position among contemporary environmental protection methods.

Cases of Using GCL Effectively

- Landfill Containment in Germany

The German project being quite famous utilized Geosynthetic Clay Liners for the landfill containment system for hazardous wastes. There were some issues with the site related to chemical leachate possibilities and highpressure load conditions. The employment of polymer-enhanced GCLs by the project team resulted in superior containment performances, well within the stringent European environmental standards. The post-installation monitoring of about 5 years showed that there was no meaningful migration of leachate, hence underlining the efficiency of GCLs in such scenarios.

- Mining Rehabilitation in Australia

During a mining rehabilitation venture taking place in Western Australia, GCLs were employed for lining the tailings storage facilities. The contrast of this followed along with an arid climate and highly alkaline nature of the wastes. Being combined, GCLs with geomembranes set alternative, composite liner systems that reduced seepage rates to below 1×10⁻¹² m/s. Therefore, these new strategies not only satisfy regulatory requirements but also minimize the longer-lasting environmental footprint of mining operations. Furthermore, reports also pointed out a 30% decrease in water demand for site remediation activities resulting from efficient water management with GCLs.

- Urban Wastewater Lagoon, US

Massive volumes of wastewater were processed by the urban wastewater project of California designed to line the lagoon system through its application of GCLs. Due to the lightweight property of GCLs, the project cost and installation time were both drastically reduced, enabling the plant to become operational within the scheduled time. Hydraulic conductivity less than 5×10⁻¹¹ m/s was proven during testing, providing the best long-term containment. Besides, the establishment of green infrastructure was also aided by the use of GCLs, reducing the need to extract thick clay layers from nature.

- Flood Protection in the Netherlands

To tackle increasing risks of floods, Dutch levee reinforcement schemes integrated GCLs into major flood defense assets. The flexibility and swelling property of bentonite within GCLs enhanced the impermeability and strength of the levees while being adaptable to the soiled conditions. A post-construction assessment also revealed about a 60% improvement in seepage resistance versus traditional approaches, marking its potential for climate change resilience.

These cases attest to the efficiency, flexibility, and cost-effectiveness of GCLs in a variety of applications. This, together with the advances in materials technology and strategic application, continues to keep GCLs on top of choices for geotechnical and environmental projects worldwide.

Future Trends in GCL Application Perspectives

The cradle will see major developments in the field of GCLs, both in terms of material and project requirements. One major trend will be the use of new nanomaterials to enhance the hydraulic performance and durability of GCLs. Recent studies indicated that the incorporation of nanoclay or graphene-based materials can enhance impermeability by as much as 30%, substantially improving their effectiveness in preventing seepage within challenging environments.

Additionally, the need for GCLs has grown at a rapid pace due to the infrastructure for renewable energy, such as solar power plants. According to the market analysis in 2023, the increase in solar farm projects involving GCLs has been recorded at around 18% over the past two years, ascribed to their ability to offer long-term stability and reduce maintenance costs. Further, there is a simultaneous development in the manufacturing processes allowing GCLs to be produced in an environmentally conscious way from recycled materials, adhering to the global spirit of sustainability.

Another important growth area concerns designing multi-layered GCL systems, which address harsh conditions such as high pressure or heavily contaminated sites. Such designs combine different geotextiles and bentonite formulations, thereby increasing their usability for applications in oil and gas, mining, and hazardous waste containment. Future research and development are expected to focus on predictive modeling tools, so engineers can more reliably assess long-term performance of GCL installations, thereby ensuring reliability across various industries.

Reference sources

1. Evaluation of hydraulic conductivity and self-healing potential of punctured geosynthetic clay liner

- Authors: A. Dixit, Deepesh Singh, S. K. Shukla

- Journal: International Journal of Geotechnical Engineering

- Publication Date: May 27, 2024

- Citation: (Dixit et al., 2024, pp. 502–516)

- Summary:

- This study investigates the hydraulic conductivity and self-healing capacity of modified geosynthetic clay liners (GCLs) by replacing encapsulated Sodium Bentonite (Na-B) with varying percentages of locally available black cotton soil (BCS).

- Methodology:

- Experimental tests were conducted on GCL specimens with punctured holes of 4, 8, and 12 mm in diameter.

- The hydraulic conductivity was measured using an improved triaxial apparatus, and self-healing capacity was assessed by analyzing the performance of the specimens over 24, 48, and 72 hours.

- The permeant used in the tests contained heavy metals based on leachate analysis from a municipal solid waste site.

- Key Findings:

- The study identified the optimal mix of Na-B and BCS that resulted in the lowest hydraulic conductivity and highest self-healing potential, suggesting that BCS can effectively serve as an impermeable barrier for leachate percolation.

2. Analytical Solution for Contaminant Transport through a Soil–Bentonite (SB)/Geosynthetic Clay Liner (GCL)/Soil–Bentonite (SB) Composite Cutoff Wall and an Aquifer

- Authors: Ming-Qing Peng, Zhi-Chao Qiu, Zhang-Long Chen, Hui Xu, Si-Liang Shen, Jia-Jie Zhou

- Journal: Processes

- Publication Date: July 16, 2024

- Citation: (Peng et al., 2024)

- Summary:

- This research develops a one-dimensional analytical solution for contaminant transport through a composite cutoff wall system consisting of soil-bentonite and GCL.

- Methodology:

- The study utilized toluene as a representative contaminant and analyzed the effects of hydraulic gradient and hydraulic conductivities of GCL and SB on contaminant transport.

- The solution was compared with an existing double-layer model to validate its accuracy.

- Key Findings:

- Increasing the hydraulic gradient significantly reduced the concentration breakthrough time and mass flux breakthrough time.

- Lowering the hydraulic conductivities of GCL and SB enhanced barrier performance, indicating that GCL can reduce the required thickness of the cutoff wall compared to soil-bentonite walls.

3. Hydraulic and Geochemical Characteristics of a Geosynthetic Clay Liner Exhumed from an Exposed Composite Liner

- Authors: Thomas R. Williams, Craig H. Benson, K. Tian, Nazli Yeşiller, James L. Hanson

- Journal: Journal of Geotechnical and Geoenvironmental Engineering

- Publication Date: May 1, 2024

- Citation: (Williams et al., 2024)

- Summary:

- This study examines the hydraulic and geochemical properties of a GCL that was exhumed from a composite liner system after being exposed for 12 years.

- Methodology:

- The research involved laboratory tests to assess the hydraulic conductivity and geochemical characteristics of the exhumed GCL.

- Key Findings:

- The results indicated changes in the hydraulic performance of the GCL due to long-term exposure, highlighting the importance of monitoring GCLs in landfill applications.

Frequently Asked Questions (FAQs)

What is a geosynthetic clay liner (GCL)?

A geosynthetic clay liner (GCL) is a hydraulic barrier composed of bentonite clay sandwiched between two layers of geotextile. Generally, it serves in landfills or mining to provide containment and stop contaminants from migrating.

How does a GCL compare with compacted clay liners?

As against compacted clay liners that require several feet of compacted clay for a barrier, geosynthetic clay liners are more efficient. GCLs, being thinner and easier to install, provide containment with reduced material requirements.

What benefits are obtained from placing GCLs on steep slopes?

Placing geosynthetic clay liners on steeper slopes improves hydraulic protection owing to their lightweight and flexible design. GCLs conform more closely to slope contours, thus preventing erosion and keeping layer distribution even.

How does internal shear strength affect GCLs’ performance?

In situations where increased internal shear strength is needed, GCLs can be enhanced by needle-punched composites that add stability and can bear higher loads, suitable for high-load applications.

What role do geotextiles play in GCLs?

The geotextile outer layers in GCLs serve several purposes: mechanical reinforcement, drainage, as well as to avert the loss of granular bentonite. The bentonite layer in between two geotextiles ensures durability and performance in many different conditions.

Can GCLs apply to secondary containment?

GCLs can indeed be used for secondary containment applications. They provide an additional layer of barrier protection to enhance primary containment systems, hence increasing full safety against environmental contamination.

How does the thermal lock geosynthetic clay work?

The thermal lock geosynthetic clay uses a unique bonding facility wherein the performance of the GCL is enhanced when exposed to high temperatures. Thus, this feature ensures that the liner will retain its integrity and effectiveness under extreme conditions.