High-Density Polyethylene (HDPE) liners have found their way into different industries like construction, agriculture, waste management, and even environmental protection. Being the most durable, flexible, and chemically and weather resistant liners, the HDPE geomembranes are the ones that the environment relies on most and the industry that delights through others’ efficiency. However, with the presence of a myriad of manufacturing companies in the industry, how would you find the right one that offers quality products, reliability, and innovation? This blog is about the manufacturers of HDPE liners who have stood out at the top and their characteristics of excellence.

Overview of HDPE Liners

What Are HDPE Geomembranes?

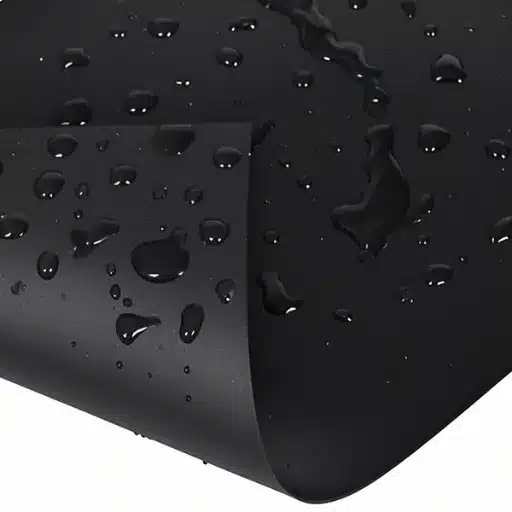

High-Density Polyethylene (HDPE) geomembranes are synthetic materials which are commonly utilized in environmental, geotechnical, and civil engineering projects and are defined by their resistance to chemicals, long life, and non-permeability which are superior to other materials. These geomembranes consist of high-density polyethylene resin and they are fabricated in such a manner that they work as superb barriers preventing water, chemicals, or contaminates to penetrate the ground beneath them.

HDPE geomembranes are known as super tough and strong materials with high tensile strength on one hand, while on the other hand, they possess the same UV resistance, so they would be a perfect choice for the outdoor applications such as landfills, wastewater treatment ponds, mining operations, and canals. Industry data suggests an average lifetime of more than 25 years for HDPE liners in ideal conditions; however, the lifetime may vary with the location of installation, exposure to chemicals, or sunlight.

Applications of HDPE Liners in Various Industries

1. Mining Industry

The miners’ use of HDPE liners is very wide, and among the mining operations are heap leaching, tailing ponds, and wastewater management, etc. The use of these liners not only restrains the hazardous chemicals but also aids in the prevention of pollution of the surroundings due to this. World statistics indicate that more than 80% of mining operations are using some type of membrane, and the most common one being HDPE due to its chemical resistance and UV stability.

2. Agriculture and Aquaculture

To reduce the seepage loss, HDPE liners are used in irrigation ponds, water reservoirs, and canals in agriculture. It is reported that farms using these liners save roughly 30% more water than unlined systems. Similarly, for aquaculture, HDPE liners are used to control the environment in fish and shrimp farming thus increasing productivity while at the same time lowering the risk of diseases.

3. Landfills and Waste Management

With their extremely low permeability, HDPE geomembranes serve as the main barrier for landfill construction. They prevent leachate from reaching underground water sources and polluting them. A research study on environmental issues conducted in 2021 revealed that the installation of HDPE liners could lower the risk of groundwater pollution by as much as 95% in sanitary landfills. Therefore, their strength is capable of extending the operational lifespan of waste disposal units.

Advantages of HDPE Liners

Durability and Longevity of HDPE Liners

HDPE liners have the same huge durability and long life span, making them the top choice in many industries. First of all, the chemical breakdown and UV rays had a good resistance. When covered and protected from direct sunlight, high-density polyethylene liners have been proven to last over 50 years even if the environmental conditions are not friendly. This durability is said to be because of the materials’ strong molecular structure and their ability to endure tension without breaking.

In addition, HDPE liners have a higher resistance to thermal aging compared to other geomembrane materials like PVC or LLDPE. Reports indicate HDPE liners having a wide application range since sustaining their performance from -40°F to 176°F (-40°C to 80°C). Besides, the accelerated weathering tests have shown that the tensile strength and the flexibility of the liners are preserved for decades which is a great reassurance for long-term projects.

Cost-Effectiveness and Efficiency

In conclusion, HDPE liners are very much cost-effective and operationally efficient products, so they continue to be the first choice for many industries. According to the latest statistics, the initial installation cost of HDPE liners is much lower compared to many other geomembranes. In particular, their long life span translates to a great reduction in the long term costs associated with maintenance. For example, the reports mention that HDPE liners can still last up to 20-30 years even in harsh environments thus the frequency of replacements is being reduced which is especially the case with not so frequent ones.

In addition, their trait of being impervious to chemical degradation assures that there will be no leaks or damage and consequently, less money will be spent on environmental clean-up. The mining and wastewater treatment industry has estimated, as much as, 40% savings during a liner’s lifecycle when the change is made to HDPE liners. Furthermore, the low weight characteristic of the liners makes their transportation and installation easier thus resulting in savings of labor costs and shorter project timelines.

Selecting Reliable HDPE Liner Manufacturers

Key Factors to Consider When Choosing a Manufacturer

Reputation and Experience

In the matter of HDPE liners, it is sensible to choose the manufacturers whose claims are supported by a strong history of accomplishments and lot of experience. Reputable companies typically possess a tremendous amount of industry knowledge and a long trail of satisfied customers’ opinions over many years. To give an example, companies with a presence of more than 20 years have the competence and expertise to effortlessly cater to the needs of different industries.

Material Quality Standards

Make sure that the manufacturer has got an assortment of quality certifications like ISO 9001 or the internationally acknowledged ASTM standards. Such assurances mean that the HDPE liners produced by the company will go through strict quality checks and hence will be of high-performance nature and safe as well. The liners of high-performance type are to be unbelievably resistant to UV degradation, chemical exposure and even physical wear, and thus, they can be considered to have a very long functional life.

Customization Options

The manufacturers who are reliable provide custom services that meet the specific needs of the project. Those things enable customization of liner thickness, widths and lengths so that they are fully adjusted to the particular operational needs. For instance, mining projects may require very robust liners with a thickness of at least 1.5mm so that they can support the weight of heavy loads.

Evaluating Manufacturer Credentials and Certifications

While it is necessary to assess a manufacturer’s credentials and certifications, adherence to industry standards is one of the most significant aspects of the selection process for an HDPE liner manufacturer. It is a very clear sign of the ability to produce quality products and ensure customer satisfaction when a large number of manufacturers rely on the ISO 9001 certification for their quality management system. In addition, the ISO 14001 accreditation, which represents the environmental management commitment of a company, is a perfect example of how the sustainable practices considered essential in today’s industrial world are in line with the environment-friendly policies.

Another crucial certification to keep in mind is GRI-GM13 compliance, which is the worldwide norm for HDPE liner material. So, the liners will not only meet but also exceed the required standards for thickness, tensile strength, and chemical resistance; thus, they will be suitable for the most challenging cases of environmental containment and industrial projects.

Leading HDPE Liner Manufacturers by Region

1. ShengXing (Shanxi Shengxing Building Materials Sales Co., Ltd)

Shanxi Shengxing Building Materials Sales Co., Ltd., which goes by the ShengXing name, has become a leading supplier in the HDPE (High-Density Polyethylene) liner production and sales industry. The company, with its location in Shanxi Province, China, is not just a manufacturer of geosynthetic materials and building construction products but also a seller who provides the market with the cheapest waterproofing and containment solutions.

ShengXing’s favorable location in Shanxi Province, one of the largest industrial areas in China, allows the company to easily access raw material suppliers, transportation networks, and production facilities. This site not only supports the company’s production capabilities but also provides easy access to the markets in different regions through the distribution channels. The company runs its activities via an online platform at constcmart.com, which allows customers from all over the world to have easy access to product information, technical specifications, and buying processes.

2. Solmax

Solmax, which started off in Canada in 1981 as a geosynthetics distributor, has over the years become the world’s biggest geosynthetics manufacturer with presence in 58 countries across all continents. The company has turned a regional distributor into a global powerhouse manufacturing one and this among the most significant success stories of the industry. In 1997, Solmax moved from distribution to production by setting up its first plant in Canada, which was the start of its vertical integration strategy.

The company’s rapid growth was then made possible by the acquisition of industry leaders which was a part of their plan. In 2017, Solmax purchased GSE Environmental thereby acquiring the advanced geomembrane technology and the North American and Asian market presence. The monumental acquisitions of TenCate Geosynthetics and Propex in the year 2021 further strengthened Solmax’s position as the largest producer of geosynthetics in the world. In addition to the acquisitions, the complementary product lines, manufacturing know-how, and the established customer relationships have all contributed to Solmax’s diversifying and enhancing comprehensive solution offerings.

3. AGRU America (Subsidiary of AGRU Kunststofftechnik GmbH, Austria)

AGRU Kunststofftechnik GmbH was set up in 1948 by Alois Gruber Sr. in Bad Hall, Austria, first as a locksmith business then changing over to anodizing and finally producing plastic pipes in 1961 which was a bold move that turned the company into one of the world’s top engineering plastics manufacturers. The company’s entry into geomembrane production came in 1985 when it built a production line of its first polyethylene liner at Waldneukirchen that could produce 5-meter wide liners using the state-of-the-art calendering technique.

AGRU America came into being in 1988 with a plant in Boston, Massachusetts, this was the first international expansion of the company and it also meant that the North American market would be supplied with local products thus the company’s commitment to that market was underscored. In the mid-1990s, when Mag. Alois Gruber (the founder’s son) was at the helm, AGRU America moved to Georgetown, South Carolina which allowed the company to more than triple its production capacity and also to position itself perfectly to supply the fast growing geosynthetics market. A second U. S. facility was built in Fernley, Nevada in 2008 to ensure quick deliveries to the western mining industry.

4. BPM Geosynthetics (The Project Material Co., Ltd)

BPM Geosynthetics, under the name The Project Material Co., Ltd, has been set up in 2007 China and has extremely fast grown to become one of the top HDPE geomembrane and geosynthetic materials manufacturers and exporters in Asia. The company has been in the industry for more than 15 years and has built a reputation for selling high-quality products at low prices to customers in more than 80 countries in North America, Europe, Southeast Asia, the Middle East, and Africa.

BPM has a new manufacturing plant that is located on a 16,000 square meter area with state-of-the-art automated production lines and professional testing equipment. The company has a team of 120 senior technical experts who are engaged in the research, development, and production of geosynthetic materials. The company has an impressive yearly output capacity of 2 million square meters (or about 80,000 tons) which enables BMP to manage very efficiently large-scale infrastructure projects as well as smaller custom orders. Since its establishment, the company has already supplied more than 100 million square meters of geomembranes, thus proving its manufacturing capacity and market acceptance.

5. Layfield Group

The company has successfully positioned itself as an international player in the geosynthetics sector by setting up manufacturing facilities and distribution centers in North America, Europe, and Australia. Layfield’s reputation as a one-stop shop for containment and environmental protection solutions is built on the products it offers like geomembranes, plus the complementary products and the installation accessories.

Over the five decades of operations, Layfield has gained very useful knowledge in a wide range of applications starting from environmental containment to agriculture. Enviro Liner® which is the company’s main product line, the geomembranes, is recognized for its superior pliability and strength that allows their application in both drilling fluid containment and hazardous waste management systems. Also, Layfield has cooperated with top material manufacturers globally so it can provide both exclusive products as well as even more selected third-party solutions that meet rigorous quality control criteria.

6. NAUE GmbH & Co. KG

NAUE GmbH & Co. KG was established in 1964 in Germany and with the help of its six decades of engineering excellence and innovation has emerged as one of the major manufacturers of geosynthetic products in Europe. The company’s headquarters are located in Espelkamp, Germany and it has the operating structure of a family-owned company that uses German engineering precision alongside its extensive geosynthetic solutions dedicated to civil engineering, environmental protection, and hydraulic engineering applications all over the world. NAUE has made its presence felt as a technology leader mostly in the European market while at the same time increasing its global presence through the setting up of strategic partnerships as well as subsidiaries.

NAUE’s product development policy is based on complete system solutions rather than just the provision of individual components. The company has automated the best and freshest production process and equipped it with the best machines possible in Europe in order to guarantee the highest quality output of its products. It has also established subsidiaries and production partnerships in Northern, Southern, and Eastern America, and Asia. NAUE is well-known for its geocomposite products which allow for the integration of a wide range of geosynthetic functions into a single-component solution, thus making installation faster and boosting the performance of the whole system. The company is committed to spending a large portion of its budget on R&D and that is why it often collaborates with universities and research institutes to push the limit of what is possible with geosynthetics in the area of technology and application techniques.

Current Trends and Innovations in HDPE Liner Production

Advancements in HDPE Geomembrane Technology

High-Density Polyethylene (HDPE) geomembrane tech is still progressing, and it is being developed rapidly due to the cutting-edge research and the increasing demand in primary industries like construction, mining, and environmental engineering. The liner’s durability, flexibility, and overall performance have experienced giant leaps.

Among the top most remarkable examples of development is the introduction of the multi-layer co-extruded HDPE liners which merge the diverse polymer properties into a single layer. These liners not only increase the resistance to chemical and UV deterioration but also have the highest resistance to cracks due to stress. Studies have demonstrated that co-extruded geomembranes with certain additive modifications, including antioxidants and stabilizers, can extend the life span of liners by as much as 50% in extreme environmental conditions.

Emerging Applications of Geomembranes

Mining Industry

In heap leach mining, geomembranes are becoming more critical in the abortive process of precious metals like gold and silver as well as copper. Over the next five years, the mining sector’s global growth is estimated at 5% per annum, and in that case, the demand for geomembranes in this industry will surely rise remarkably. These liners take the non-leaching of toxic chemicals to the environment around them hence they are enabling and maintaining eco-friendly and safe mining practices.

Agricultural Pond Liners

The agriculture sector is increasingly dependent on geomembranes when it comes to determining the key of irrigation ponds, canals, and reservoirs. The global market for agricultural water storage systems is anticipated to grow at a controlled rate, while geomembranes come forward as an economical and pollution-free alternative for the storage of and quick access to water. Their impermeability is a major plus for the cutback of water loss through seepage.

Renewable Energy Projects

Switching to green energy sources, the world is going to be the major Gypsum market using geomembranes primarily in the manufacturing of solar panel arrays and the generation of biogas. For example, geomembranes are excellent for the cover of anaerobic digesters in biogas plants, thereby, increasing energy capture, and keeping the plant in compliance with environmental regulations.

Reference Sources

-

Structured Geomembrane Liners in Landfill Base and Cover Systems

This document discusses the manufacturing processes for HDPE and LLDPE liners, providing insights into the industry standards and applications.

Source: University of Kentucky -

Engineering Properties of Commercially Available HDPE Liners

This research evaluates the specifications and properties of HDPE liners, including thickness and performance metrics, based on manufacturers’ data.

Source: Iowa State University -

Lecture on Geosynthetic Clay Liners and Geomembranes

This lecture provides an overview of geomembrane manufacturing, including extrusion processes for HDPE liners, and their applications in waste containment.

Source: MIT OpenCourseWare

Frequently Asked Questions (FAQs)

What are the key features of hdpe geomembrane that make it a versatile material?

The hdpe geomembrane features are the ones that include among others, superior chemical and waterproofing properties, and very good tensile strength, plus being highly resistant to puncture and wear. The geomembranes are offered in smooth and textured finishes (textured geomembranes), various mil thicknesses including 40 mil hdpe liner equivalents and thicker alternatives conforming to ASTM requirements.

What installation methods and weld techniques are used for hdpe geomembrane liner projects?

To get impermeable seams that cater to ASTM and engineering applications, the HDPE panels are connected using either extrusion or fusion welding techniques. Weld testing, skilled labor, and quality control are crucial in the process of ensuring seam strength and avoiding leaks. The combined use of trained installers and following project-specific procedures will lead to a significant reduction in installation defects, resulting in considerable savings over the life of the system.

How do geosynthetics like geotextile and textured geomembranes work together in containment?

Nonwoven geosynthetics like geotextile are typically positioned under or over the hdpe liner to provide a deterrent against forceful puncture, which is more or less unique to the location of the liner, and to prevent any migration of fluids underneath the liner by controlling drainage in the area. Textured geomembranes increase the friction on steep slopes, consequently enhancing their stability. The pairing together of geotextile and geomembrane in lining projects guarantees less installation risks and corresponds to an extension of the high-performance life of the system.

What are common applications for hdpe and lldpe geomembranes in reservoirs and lagoons?

The application of HDPE and LLDPE geomembranes is broad as they are used in reservoir liners, wastewater lagoons, and mining containment, alongside landfill lids and caps, and hydrocarbon containment. They are the most commonly used geomembrane in containment applications requiring high quality and long-lasting performance due to their non-permeable nature, excellent chemical resistance (including alkali and hydrocarbons), and capability to endure harsh environments.