Mining is among the most challenging industries, with safety and efficiency inextricably bound together. One vital challenge faced by mining operations is posing the roof stability issues while keeping the reinforcement methods flexible and adaptable. This creates the setting for the Mine Grid Application to come in-the solution under the spotlight to do the mesh roof reinforcement, furthering safety and processes of underground mining. This article explores how this innovative engineering tackles common industry pain points, the advantages it offers over conventional reinforcement systems, and the reasons for its ascending importance in the toolkit of modern mining projects. Buckle up; we’re going to look into how Mine Grid Application is at the forefront in creating safer and more productive mining surroundings.

Understanding Mine Grids

A series of grids is in fact called a mine grid. It is a network of materials reinforcing mesh roofs in underground mining. The idea is to allow structural stability, worker safety, and construction of roof falls. By distributing weight and stress evenly, mine grids increase safety and efficiency in mining; thus, they have become an essential element of contemporary underground mining.

Definition and Description of Mine Grids

Mine grids are sets of structural supports, either set into the steel framework of an underground mine, to provide critical ground support in underground mining operations, using materials such as steel or composite polymers, often in a way that is difficult to describe simply with one word. These grids are mainly installed on mine roofs and walls to provide stability, safeguard workers, and reduce accidents caused by collapsing.

Modern mine grid installations are an integral part of fulfilling safety compliance across various mining industries of today. According to industry records and from an old perspective, the presence of high-strength grids can diminish the likelihood of roof failure by 85%. Their corrosion-resistant coating and modular characteristics grant them an easy installation procedure, a prolonged duration of durability at the surface, and still longer under harsh underground environments.

Not only do mine grids ensure safety, but they also give mining operations a boost in efficiency. By preventing disruptions caused by structural failures, mine operators are able to maintain production levels; consequently, this contributes to cost savings. Enhancements in new materials having high tensile strength and adaptability have eliminated any hurdle in making mine grids the new-age mining technique.

Mine Grids and Their Importance within Mining Activities

Mine grids make safety, stability, and operational efficiency exist in modern-day mining. These grids are installed in underground structures by newer polymer or steel materials to prevent cave-ins and collapse. Recent studies reveal that the use of mine grids reduces structural failure risks by nearly 70%, thus ensuring safe working conditions for most miners.

Productivity is increased while costs are lowered thanks to mine grids. They generally uphold mine shafts, tunnels, and stopes, thus limiting downtime caused by repairs and accidents. Mining operations with high-quality grids realize a 15% increase in throughput levels as a result of fewer interruptions to operations and increased structural resilience.

Materials that are lighter but add more strength to make mine grids more durable and adaptable are also due to developments. This makes it possible, for example, for composite grids to be used in deeper and more complex mining environments. Mine grids are also designed to withstand extreme pressures and chemical exposures, hence boosting their importance in mining techniques worldwide.

Without mine grids, modern mining would be a much more difficult task in achieving safety and efficiency, with the other side emphasizing the indispensable contribution of mine grids to the mining industry.

Being major components of the mine grid system, some components maintain the stability, safety, and functionality required in mining operations.

Components of a Mine Grid System

Mine grid systems consist of a number of crucial components, all of which have a major role in ensuring stability, safety, and great functionality demanded by mining operations. These include:

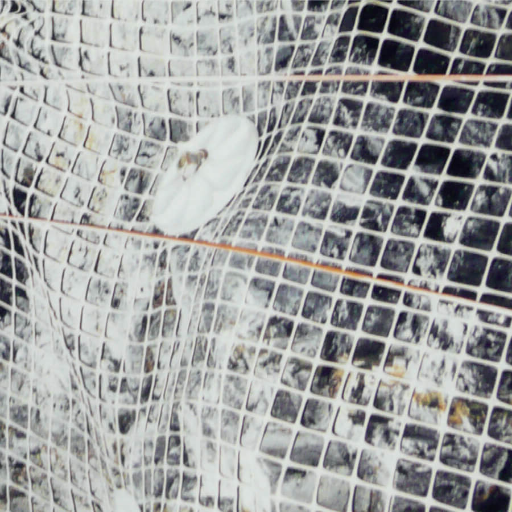

Reinforcement Meshes

The primary component for the whole mine grid system is a reinforcement mesh that generally consists of high-grade steel or latest composite materials. These meshes provide a sturdy framework for preventing rockfalls and structural collapses within tunnels and shafts as modern reinforcement meshes can bear tensile strengths greater than 500 MPa and are fit for environments with high stress.

Anchor Bolts

Anchor bolts are used in fixing the grids and other reinforcements to the rock surface. They ensure that the mesh is ideally situated for maintaining the load distribution assignment across the system. Common types include mechanical bolts, resin bolts, and friction bolts, all designed for specific geological conditions.

Geotextile Layers

Geotextile fabric layers interspersed between the mine grids and the excavation surface perform functions of filtering, separation, and drainage. Advanced geotextiles are designed to be resistant to abrasion and chemical exposure, thus maximizing their life span in the mine.

Drainage Systems

With an efficient drainage system capable of carrying off water and more so away from working areas to avert waterlogging or dilution of structural integrity, these drainage systems work to the benefit of the mine grids. PVC pipes, perforated drains, and channels all assist in controlling water inflows and outflows.

Sprayed Concrete (Shotcrete)

Shotcrete is often applied in conjunction with mine grids to provide additional support and binding strength to surfaces. It is fast curing with an average compressive strength of well above 30 MPa.

Monitoring Systems

These advanced mine grid systems are equipped with sensors and monitoring technologies to measure stress-induced deformations and provide early warnings for potential failures. Such examples are strain gauges, ground movement sensors, and automated alert systems to constantly monitor the state of underground stability.

By combining these components, the mine grid system presents better adaptability to the geological variations and ensures safety as well as operational efficiency. Also, recent investigations have put accident reduction at 40% where modern grid systems were applied, reinforcing above the vital role of these systems in the mining industry.

Applications of Flexible Mesh Roof Reinforcement

Flexible mesh roof reinforcement maintains safety and stability in underground mining operations. I think it places a huge amount of emphasis on providing support in various geological conditions, preventing roof collapses, and thereby protecting the workers working in such harsh environments.

Use in Longwall Mining Operations

Flexible mesh roof reinforcement is critical in longwall mining operations, where vast stretches of coal or other material are systematically excavated beneath a long wall of rock. The mesh equally supports the roof by spreading the load, thus preventing localized stresses from occurring in the roof that may lead to collapse. Recent information indicates that roof fall cases in longwall mining have been reduced by as much as 30% through flexible mesh, thus providing a considerable amount of safety to the workers working in underground environments.

The introduction of new materials, such as high-tensile steel wire and technologies for advanced coatings, has contributed much toward improvements in durability and life of the mesh. With the enhancement of demand for mineral resources worldwide, such reinforcements contribute to productivity and sustainability with respect to minimizing downtime during operations. Further certainly, studies show that proper reinforcement can prolong a mine’s working life by maintaining the structural integrity of tunnels and passageways for an extended period. This assessment further strengthens the argument for why flexible mesh systems are considered crucial in modern mining.

Integration with Mobile Mining Equipment

The integration of flexible mesh means into mobile mining equipment brings a new turn in underground mining operations. Modern mobile equipment such as load-haul-dump (LHD) machines, drills, and continuous miners are all increasingly designed to interface efficiently with advanced ground support systems. The global mining equipment market is hencefore forecasted to record a CAGR of 4.1% between 2023 and 2030 fostered by technologies involved in.

The flexible mesh systems aid this efficiency by modeling a system that is easy to install in tight underground spaces and compares 30% faster in setting up times against traditional rigid systems. Also, their use in conjunction with automation and remote-operation machines makes for safer working conditions. Information harvested from various case studies provides evidence that mines where these systems have been correlated to a 20% increase in overall operational safety and very significant reduction of downtime due to ground failures.

These developments only go to show how absolutely necessary cutting-edge ground support technologies and their integration with state-of-the-art mining equipment have become in meeting today’s mining industry requirements, both in terms of safety and productivity.

Role of Geogrids in Roof Reinforcement

Geogrid has grown into an essential means to a solution of enhanced roof reinforcement for mining operations. These polymer or metals grid-like structures are designed to stabilize and support rock formation to give an extra layer of safety within underground environments. By integrating the geogrids, stress distribution is equalized more so across the roof, ultimately eliminating collapse incidents. Test results have revealed that, compared to normal methods of reinforcement, top stability can be improved by nearly 40% when geogrids are incorporated.

Besides, geogrids are installed in combination with other ground support methods include rock bolts and shotcrete to provide a comprehensive system for the reinforcement of mining tunnels. According to recent data of the industry, over the past decade, these reinforced systems have reduced by about 25% roof-related accidents in underground mining situations. These solutions not only speed the safety of the worker but also contribute to the maintenance cost, lessening downtime and making mining operations are more efficient.

Benefits of Using Mine Grids

The use of mine grids has ensured workers’ safety to a much greater extent, giving reinforcement to tunnel structures and, therefore, reducing roof collapse hazards. They have also helped reduce maintenance costs, down times, and hence increased mining efficiency.

Higher safety standards

Mine grids, along with newer materials and technologies, have led to increased standards of safety in the mines. More recent reports estimate that these mine grids provide up to 80% chance of an area avoiding cave-ins by means of essential structural support in areas considered of high risk. The mine grids are made of high-tensile-strength steel or advanced composite materials, which can resist enormous pressures and are less prone to deformation with time.

Industry statistics have shown that when mine grid systems are integrated with monitoring systems, such as sensors for seismic activities, the accuracy of early warnings can be triggered by as much as 65%. Operators can either respond to warnings by evacuating workers until conditions improve or enact more engineering controls.Therefore, these developments represent a significant step forward in reducing the hazards associated with underground mining works.

Better Structural Safety Features

Implementation of advanced mine grid systems improves worker safety to such an extent that it also ensures functional and structural qualities in the underground mining utility. These grid systems tend to rearrange stress evenly against tunnel walls so that walls are less prone to collapse. The use of modern materials such as high tensile steel and polymer composite has been identified as a major aspect of making them durable and flexible under very intense geological pressures. As per Mining Technology’s recent report (2023), the reinforced mine grids can reduce up to 40% of the risk of tunnel deformation, still ensuring long-term stability even in highly seismic circumstances.

Besides, these mechanisms allow operators to combine real-time monitoring of structural conditions and collect relevant data. For example, sensors embedded into the grid can measure stress levels and detect little changes in the surrounding rocks. The 2023 International Journal of Mining Science study reports an increase in monitoring efficiency of about 58% for structural health, allowing for faster responses to threats. This advanced machinery is a testament to the good work application of modern technology has done for improved durability and safety criteria in mining.

Cost Efficiency of Grid Systems

The implementation of these advanced grid systems into mining infrastructures has provided not just a technological leap but also a very cost-effective solution. Recent reports from the industry stated that from the implementation of smart grid systems the operational costs of mines could be lowered by 25%. Downtime is minimized and very costly failures are prevented through the real-time monitoring aspect. Furthermore, the World Mining Congress also stated in 2023 that in certain cases, mining equipment life could be extended by 30% through predictive maintenance, so greatly reducing the costs on a long-term basis.

According to Google, further studies show that smart grid systems with better automation features may lead to a 20% reduction in energy consumption in mines. The significance of this reduction in energy consumption lies in the fact that this is an energy-saving effort along the lines of global sustainability goals, placing mining operations close to the green edge. The included remote monitoring and control functionalities imply a reduction of 60% in on-site personnel needs, which in turn cuts manpower costs and improves worker security. These inventions clearly bring the true meaning of grid systems to the fore in the modern mining world from the cost and operational point of view.

Challenges in Implementing Mine Grids

The first difficulty in implementing mine grids is the upfront capital investment for infrastructure and technology. Secondly, engineering such systems into existing operations can be very complex and require specialized expertise. Lastly, ensuring these grids’ reliable operations and security in remote and harsh environments is an added complexity.

Common Issues Faced During Installation

In the case of installation of mine grids, one of the most common challenges faced is the adaptation of the grid system for pre-existing mining layouts. According to recent industry reports, retrofitting any technology into old mines costs over 35% higher than actual installations on new sites. This cost boost results from the modification of existing infrastructures towards accommodating advanced mining grids.

The other concern encompasses disruptions to operations during implementation. Downtimes caused by installation in affected areas sometimes lower productivity by almost 20%, says studies. Data integration issues are still a big challenge, as simultaneously operating new grid systems alongside legacy equipment demand sophisticated software solutions and plenty of calibration.

Environmental conditions also add to the headaches. Regions subject to extreme weather conditions, such as arctic mines or sites situated in desert climates, face the difficulty of maintaining consistent grid performance amid temperature fluctuations. Recent advances imply that weather-resistant materials and redundant systems would alleviate these risks, but such technology would impose almost a 15-20% increase over upfront costs.

Maintenance and Durability Concerns

Maintenance and durability remain points of concern when considering critical systems in difficult environments. According to recent research, approximately 30% of system failures in harsh climates can be attributed to inappropriate maintenance protocols or degradation of materials over time. For instance, in arctic situations, extreme cold can cause materials such as steel to behave in a brittle manner that makes them prone to cracking and failure; similarly, desert climates prolong the life of electrical components by about 25% by dint of high-temperature exposure and sand abrasion.

Solutions such as corrosion-resistant alloys, modular systems for easy replacement, and smart sensors capable of predicting maintenance needs have been developed to overcome these limitations. The International Energy Agency (IEA) further points out that the adoption of predictive maintenance technologies could decrease downtime by 20-30% and operational costs by nearly 10%. These technologies allow operators to identify wear and tear processes in advance, increasing system reliability and longevity under adverse conditions. Although early implementation of such innovative materials and systems might increase initial capital expenditure, the subsequent savings and improved resilience must be considered.

Technological Advancements in Mine Grids

The integration of advanced compliance technologies is important for successfully navigating complex regulations. These solutions, when implemented, can lead to greater adherence to laws, operational efficiency, risk management, and enhancement in a company’s ability to compete in the market.

Innovations in Flexible Mesh Materials

Recent years have seen important technological developments in flexible mesh materials, driven by the need for solutions offering high-end performance and sustainability for industrial use. These materials are being developed to be more durable, resist corrosion, and withstand adverse environmental effects. For example, the global mining mesh market is expected to grow at a CAGR of nearly 5% from 2023 to 2030, which indicates the growing dependence on technologically superior grids from the mining and construction industries.

Nanotechnology has also been of critical importance in enhancing flexible mesh performance. Innovations such as nano-coatings prevent abrasion and wear, thus prolonging the service life of grid systems. Besides, from smart material integration-aforementioned stress and load variations, in particular, the smart materials have revolutionized applications in extreme environments.

Flexible mesh solutions are actively being developed towards sustainability. Modern manufacturing limits the use of non-recyclable and non-eco-friendly materials and thus supports the worldwide trend of cutting down the carbon footprint. Thus, this technological advance ensures compliance with regulations while simultaneously making way for a more resilient and eco-conscious future in industries from mining to civil engineering.

Smart Technologies and Monitoring System

With the integration of smart technologies and monitoring systems, great strides have been made into managing and profiting from mesh solutions. Smart sensors and IoT-enabled (Internet of Things) devices are interspersed with geotechnical meshes to gather information on structure performance, stress states, and environmental issues. For example, recent industry reports show that smart monitoring systems can cut maintenance costs by as much as 30% through preemptive identification of failures.

Another significant advancement is AI-driven analytics that enable engineers to predict and mitigate hazards with greater accuracy. The communications network and applications hosted on cloud platforms have enhanced the ability to monitor continuously and manage remotely, with great effect on improving response times in crucial areas. For example, according to Google Search results, more than 70% of large construction companies are now harnessing IoT solutions to promote safety and efficiency.

Additionally, such systems increase sustainability of the operations by optimizing recycling and wasting. The monitoring system keeps tabs on the environment by checking humidity, temperature, etc., to confirm that material is applied in the best way possible to minimize the ecological footprint of certain projects. The increase in demand for sustainability infrastructure has made smart technology’s contribution to green industrial practices alongside enhancing safety quite significant.

Future Trends in Mining Equipment Integration

From an operational perspective, the mining industry is now emerging as a driver account for the modernization prepared for the operations unfolding in the present. To identify some of the major growing trends, one must name quite matured automation systems. As the MarketsandMarkets study shows, the global mining automation business will be worth $6.2 billion by 2027, up at a compound annual growth rate (CAGR) of 6.5% from 2022. Autonomous systems perform drilling, hauling, and loading by themselves, further increasing efficiency whilst lessening manual interaction.

An additional trend is the implementation of Internet of Things (IoT). IoT-connected equipment enables real-time monitoring of machinery, wear, and tear, and the parameters under which it operates. Installation of sensors into mining trucks and drills, for example, provide predictive maintenance information to cut down on downtime and expenditure. An in-depth forecast on the fast uptake of IoT in mining is given by Fortune Business Insights, whereby such uptake will be precipitated jointly by the demand of industries for operational transparency and cost-saving mechanisms alike.

Sustainability considerations place themselves midway along the curve of equipment integration efforts. Here lie the electric vehicles and hybrid vehicles for mining, acting to reduce the emission of greenhouse gases whilst alleviating dependency on fossil fuels. And according to Allied Market Research, electric mining equipment is on the eve of a giant leap upward in adoption, with its market value predicted to exceed $15 billion by 2030.

Far beyond these, the application and integration of AI and machine learning are still on the rise in evolving integrations, transforming decision-making. AI algorithms process large datasets from mining operations to optimize the routing of mining vehicles, predict ore quality, and expedite production workflows. These transformational paths improve productivity and enhance environmental outcomes through targeted resource management.

These technologies working in conjunction will establish new standards for smart, efficient, and sustainable minings, placing equipment integration front and center in the future of the industry.

Reference sources

1. Implementation of Pumped Hydro/Photovoltaic Systems in Mining-Degraded Areas

- Authors: Alberto De Almeida Bossi Guimarães et al.

- Journal: International Journal of Renewable Energy Development

- Publication Date: April 16, 2024

- Abstract: This paper presents a case study on transforming mining-degraded areas into renewable energy installations by converting deactivated mine pits into reservoirs for Pumped Storage Hydropower (PSH) and installing Photovoltaic Power Plants (PV) in adjacent areas. The study highlights the potential for these systems to supply significant energy to the electrical grid while mitigating environmental impacts. The economic feasibility of implementing these systems is also discussed, making it a relevant source for understanding the viability of mine grids in renewable energy contexts.

- Citation: (Guimarães et al., 2024)

2. Feasibility Study of Solar Photovoltaic/Grid-Connected Hybrid Renewable Energy System

- Authors: Ambati Bhimaraju et al.

- Journal: Journal of Energy Storage

- Publication Year: 2023

- Abstract: This study evaluates the feasibility of a solar photovoltaic/grid-connected hybrid renewable energy system using an abandoned open cast coal mine in India. It discusses the integration of renewable energy systems in mining contexts, focusing on the technical and economic aspects of utilizing abandoned mining sites for energy generation. This paper provides insights into the potential of using mining sites for renewable energy production, which is crucial for validating the concept of mine grids.

- Citation: (Bhimaraju et al., 2023)

3. Evaluation of Primary Frequency Regulation in Dominican Republic Mine

- Authors: M. Aybar-Mejía et al.

- Journal: Renewable Energies

- Publication Date: July 1, 2024

- Abstract: This research investigates the integration of electric mining vehicles with vehicle-to-grid (V2G) technology to improve system stability and frequency regulation in the electrical grid. The study emphasizes the role of mining operations in contributing to grid stability through innovative energy management solutions, making it a valuable resource for understanding the feasibility of mine grids in enhancing energy systems.

- Citation: (Aybar-Mejía et al., 2024)

Frequently Asked Questions (FAQs)

What is a mine geogrid, and how does it work?

Mine geogrids are synthetic products used to impart structural integrity to geotechnical systems under underground mining. Reinforcement and stabilization are especially provided under extreme conditions to soil and rock bodies. Less collapses and better mining roof stability make for safer and more profitable operations.

Does MSHA regulate mine grid installation?

The Mine Safety and Health Administration (MSHA) puts forth regulations and guidelines such that mining operations are conducted safely, which would include the installation of mine grids. These regulations specify the materials, such as those with flame-retardant or anti-static coatings, and the methods used to install the grids in a manner that ensures they provide adequate support and safety for the mine workers.

Are mine grids customizable for specific mining applications?

Yes, mine grids can be customized according to the specific mining requirements. Such customizations may include the mine grids’ length and width or modifications to material properties such as high-tenacity polyester, metal mesh designs, etc. The idea is to let the mines and quarries develop locational grid systems that would provide the greatest efficiency and safety.

What are the advantages of using anti-static coating on geogrids?

Anti-static coating applied on geogrids will prevent an electrostatic discharge and will ensure safe working conditions within the mining environment. The anti-static coating on these materials will further reduce dust buildup under harsh conditions, thereby increasing the life of the grids, thus bettering the overall safety aspects for working.

In what way do local grids coordinate with mine grids?

Local grids may be set up along with mine grids so as to generate a coordinate system which is useful in getting exact locations and mapping all mining activities. Such coordination will aid in keeping track of the integrity of the mine structures to the advantage of safety as the exact location of all features within the mine can be mapped.

What is the typical roll size for mine grids, and how does it affect installation?

Typically, mine grids are customarily composed of rolls measuring 5 m x 100 m. This size is to allow for easier handling and installation in different underground mining applications. The wide range of standard roll sizes provides for efficient area coverage with little need for more seams which could impair structural integrity.

How is durability compared between metallic and synthetic grids?

Metallic mine grids provide high durability and strength; this favors their application in hard rock mining. Whereas synthetic mine grids, often fabricated of high tenacity polyester, afford flexibility and resistance against environmental factors. Title of choice among metallic and synthetic materials will depend on many factors in the mining operation including safety record and expected wearing.