The selection of playground flooring material constitutes an essential choice for establishing a safe and fun space that children can use. Rubber playground mats have become the preferred option for parents, schools, and community spaces. The products provide outstanding safety protection because they absorb impacts to decrease potential harm while establishing their reputation for high durability and minimal upkeep. The blog post demonstrates that rubber playground mats represent the best choice for playground flooring because it will demonstrate all the benefits of the installation process and its advantages over other available choices. The guide contains complete information that will help you decide between designing a new play area or improving an existing one.

Understanding Rubber Playground Mats

What are Rubber Playground Mats?

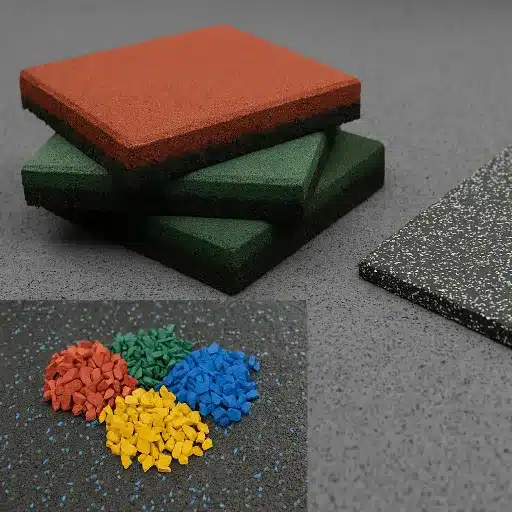

Rubber playground mats serve as specially engineered safety surfaces that function to provide cushioning and support for play areas while minimizing fall-related injury risks. The mats use recycled rubber as their primary material, which creates an environmentally sustainable product that lasts for an extended time. The products are commonly found in educational institutions and public parks as well as home playgrounds to provide better security and improved comfort. The main benefit of rubber playground mats comes from their impact absorption ability, which meets ASTM (American Society for Testing and Materials) standards that define safety testing procedures for impact protection equipment.

The mats provide various thickness options between 1 inch and 4 inches to match different falling height requirements, while their standard thicknesses protect against falls from heights between 10 to 12 feet. The materials provide strong slip protection because they maintain grip even when wet, which enables them to function as a solution for all weather conditions. Some manufacturers use UV-resistant coatings to protect their products from color fading and material decay, which results from extended sunlight exposure.

Rubber playground mats offer different design options, which enable users to create their own unique solutions because they come with multiple color choices and pattern selection, and interlocking design features. The system allows for quick installation and easy maintenance because users can replace damaged parts without needing to uninstall the whole system. The industry data shows that rubber playground mats have an average lifespan of 10 to 15 years when maintained properly, which makes them a financially wise investment that pays off over time.

Benefits of Using Rubber Playground Flooring

- Enhanced Safety

Rubber playground flooring provides safer protection against injuries than hard surfaces, which include asphalt and concrete. Research demonstrates that implementing rubber surfacing on playgrounds enables a 50% reduction of fall-related injuries. The material functions as a suitable playground surface because its shock-absorbing capacity provides effective impact protection for child play areas. - Durability and Longevity

Rubber flooring shows design properties that enable it to endure both high-traffic indoor environments and outdoor weather conditions. The contemporary rubber mats maintain their UV protection and non-slip properties, which enable them to endure extended exposure to sunlight, rainfall and extreme temperature conditions. Rubber playground surfaces maintain their functionality for up to 15 years with proper maintenance, which delivers extended cost-saving benefits. - Environmental Benefits

Recycled materials, which include old tires, make up the majority of rubber playground mats because this process helps decrease landfill waste. The production and use of these materials demonstrate their environmental benefits because one ton of rubber recycling results in the saving of approximately 700 gallons of oil. - Design Versatility

Rubber flooring offers multiple design options, which include different colors and patterns. The rubber flooring solution allows you to create custom designs that meet your visual requirements for a children’s playground and your design requirements for a more subdued environment. The surface play experience improves through the inclusion of directly applied pattern designs, which display hopscotch and other games. - Low Maintenance Costs

Rubber flooring requires basic cleaning procedures because it needs only little maintenance work. The material prevents moisture, mold and mildew from entering, which allows it to block the development of dangerous bacteria. The cleaning process requires only mild soap and water, which makes it simple to achieve clean results. The maintenance expenses decrease because users can replace damaged parts without needing to restore entire traditional flooring systems. - Improved Accessibility

Rubber playground flooring serves as an accessible surface that complies with the Americans with Disabilities Act by providing an even ground that allows wheelchair users and walking aid users to traverse the space. The playgrounds provide an inclusive atmosphere that allows every child and their caregiver to enter safely.

Rubber playground flooring delivers multiple advantages, which make it a practical, secure, and environmentally friendly solution for contemporary play spaces because it helps achieve environmental objectives while fulfilling community requirements.

Common Uses of Rubber Playground Surfaces

Rubber playground surfaces are used in multiple locations because they provide safe and sustainable, yet durable, materials. The material finds its main use in school playgrounds, public parks, daycare centers and recreational facilities. Recent research shows that rubber surfaces reduce fall injuries by 50%, which makes them the best choice for places where safety needs to come first.

Rubber surfacing has become a popular option because it needs little maintenance and lasts for many years, since most materials keep their original quality for twenty years when subjected to extreme conditions. Manufacturers produce this material with environmental sustainability in mind by using recycled rubber from old tires in their manufacturing process. Statistics demonstrate that recycling one ton of rubber results in a reduction of 2000 pounds of CO2 emissions, which helps decrease environmental pollution.

The surfaces meet federal safety requirements because they follow ASTM International standards and Americans with Disabilities Act (ADA) regulations, which enable people who have mobility impairments to use the space. The combination of safety features, sustainable materials, and functional design creates rubber surfaces as an adaptable option for contemporary play spaces and recreational facilities.

Types of Rubber Playground Flooring

Rubber Playground Tiles

Rubber playground tiles provide both long-lasting durability and safe outdoor space protection for public parks. The tiles display exceptional shock absorption capacity, which reduces the chances of severe injuries that result from falls. Playground accidents cause more than 200000 emergency room visits every year in the United States because people fall from equipment. Playground designers who use rubber tiles can effectively decrease all potential dangers associated with their designs.

The company offers rubber tiles in multiple thickness options, which range from 1 inch to 4 inches, to meet different safety standards that include ASTM F1292 fall height requirements. The product provides numerous customization choices because it enables users to select both vibrant colors and unique designs, which create visually appealing results.

The system provides multiple advantages that help to protect the environment. The production process for modern rubber tiles utilizes recycled materials, which include rubber from discarded tires, to decrease environmental waste. The recycling process of a single passenger tire into rubber material results in an oil conservation equal to two gallons.

Rubber tiles require minimal maintenance throughout their entire lifespan. The materials protect against damage caused by both weather conditions and normal use while requiring only basic maintenance and repairs that need to be done at specific times. The product interlocking system simplifies installation processes, which lets users complete their work.

Rubber playground tiles remain the top choice for indoor and outdoor play areas because they combine three essential factors that guarantee safety, long-lasting performance and environmentally friendly design.

Rubber Mulch

Rubber mulch functions as a revolutionary landscaping material that treats recycled rubber products from old tires as its raw material. Research shows that rubber mulch provides multiple benefits when compared to standard wood mulch. The material maintains its original form for many years because it does not decompose, which results in lower replacement expenses throughout its entire lifespan. The material functions as an efficient soil insulator because it maintains appropriate temperature levels while preserving soil moisture.

Rubber mulch delivers one important safety advantage because it delivers better protective cushioning, which decreases the chance of people getting hurt from falls. The material serves as a highly favored option for playgrounds because safety remains the most critical aspect. Children experience head protection from severe injuries during falls because rubber mulch fulfills the safety requirements established by the Consumer Product Safety Commission (CPSC), which governs playground equipment surface materials.

Rubber mulch provides an ecological solution through its ability to process around 110 million tires each year, which would otherwise contribute to waste problems in the United States. The practice decreases both landfill waste and greenhouse gas emissions, which would result from incorrect tire disposal methods that involve burning or dumping.

Rubber mulch comes in different colors and sizes, which makes it possible to improve the visual appeal of both gardens and play areas. Wood mulch has a higher initial cost than the current product but its long-lasting strength, combined with low maintenance requirements, makes it an affordable solution for both home and business applications.

Poured-in-Place Rubber

Poured-in-place rubber functions as a versatile, durable surfacing product that people use for playgrounds as well as walking paths and recreational areas. The process of creating a seamless surface starts with a polyurethane binder and rubber granules, which workers mix before applying the mixture to construction sites, where they shape it into custom surfaces. The recent industry statistics show that the usage of poured-in-place rubber surfaces keeps growing because of their safety features. The system provides top-notch shock absorption, which protects users from injury when they fall while complying with ASTM safety regulations.

Poured-in-place rubber maintains its performance capabilities because it withstands both weather conditions and ultraviolet radiation without requiring extensive upkeep. The material demonstrates a lifespan between 10 to 15 years when proper maintenance practices exist, which makes it financially beneficial for extended use. The outdoor surfacing solution provides multiple color options and pattern designs, which enable users to create attractive outdoor space designs. The system provides safety features for areas with high traffic and wet conditions because it prevents slipping while maintaining operational capabilities throughout different uses.

Installation of Rubber Playground Mats

Preparing the Site for Installation

The successful installation of rubber playground mats requires proper site preparation, which serves as the first step toward achieving successful results. The process begins with the complete removal of all debris and rocks, followed by the leveling of all uneven areas within the designated area. The installation process requires the ground to be leveled and compacted, which establishes a secure foundation that supports the mats. The industry standard recommends the use of compacted crushed stone sub-base material or concrete sub-base material to achieve maximum durability and drainage efficiency. The required sub-base thickness for different activities and loads falls between 4 and 6 inches because the different activities and loads determine the necessary depth.

The system requires two drainage methods which need to create a gentle slope or construct drainage channels that will prevent water accumulation. The research shows that insufficient drainage systems lead to a 30 percent reduction in rubber mat lifespan. The area needs to be measured before mat installation because this will provide the necessary information for determining mat requirements. The mats need edge trims and adhesives to keep them in place while protecting against tripping hazards. The installation of rubber playground mats creates a safe surface that maintains its strength during heavy foot traffic and all weather conditions.

Step-by-Step Installation Procedures

- Prepare the Surface

The installation area needs to be both flat and clean and dry to support proper installation work. The rubber mats require the removal of all debris and obstacles that might obstruct their proper installation. The mats will achieve better durability through correct surface preparation. - Measure the Area

The playground area needs an accurate measurement to establish the precise number of required mats. The industry standards require installation spaces between mats to allow for natural material expansion and contraction that occurs with temperature fluctuations. - Choose the Right Mats

The mats should be selected according to the safety requirements established for playgrounds. According to a 2023 study cited by industry experts, mats with a thickness of 2 to 4 inches can reduce impact force by up to 40%, minimizing the risk of injuries during falls. - Plan the Layout

The installation team should perform a mat layout test before proceeding with final installation work to choose the best layout arrangement. The seams need proper alignment to stop gaps and overlaps, which create safety hazards and make the structure unstable. - Apply Adhesives or Edge Trims

The mats need permanent installation through the use of high-quality adhesives, which will keep them attached to the ground. Edge trims and ground anchors provide sufficient support for temporary installations. Studies show that using such measures reduces trip hazards by approximately 25%. - Perform a Final Inspection

The area needs testing through walking after all mats have been installed to check their installation security and surface levelness. The organization needs to perform safety assessments at scheduled intervals for wear and tear detection and maintenance purposes.

Tips for Installing Outdoor Rubber Mats

- Choose the Right Thickness

The selection of appropriate thickness has crucial importance because it establishes the permanent strength together with the operational capacity of outdoor rubber mats. The recommended minimum thickness for mats in areas with heavy foot traffic and equipment use, which includes gym spaces and playgrounds, is 3/4 inch. Research studies demonstrate that using thicker mats enables a 50% reduction in impact force, which creates safer conditions within high-stress environments. - Ensure Proper Drainage

The mats experience water accumulation underneath them because of improper drainage, which results in dangerous, slick surfaces and gradual material breakdown. To avoid this problem, installation requires mats that contain perforations or grooves that enable water to flow freely. Experts recommend that mats be installed on surfaces that have a slight incline or through the installation of drainage systems, which should be placed beneath the mats. The project enables your mats to last approximately 30% longer than their normal lifespan. - Consider UV Resistance

The direct sunlight exposure that outdoor rubber mats experience causes them to develop fading and cracking issues. The use of UV-stabilized materials in mat construction protects products from sunlight damage. Research shows that UV-resistant mats can last two to three years longer than standard ones when exposed to harsh outdoor conditions. - Temperature Adaptability

Rubber mats undergo expansion and contraction movements because of extreme temperature conditions, which result in gap formation and warping during seasonal weather changes. The solution requires a perimeter space of 1/4 inch, which will create space for thermal expansion to occur. The environment needs temperature-resistant mats that can withstand temperature changes between -20°F and 140°F. - Use Compatible Cleaners

The proper maintenance of outdoor rubber mats determines how long they will serve their purpose. The slip-resistant texture of mats remains intact through regular cleaning, which uses mild non-abrasive solutions that prevent grime from building up. The use of harsh chemicals such as bleach and acetone should be avoided because these substances will damage the surface of the mat. Studies show that proper cleaning practices, together with regular cleaning activities, can extend the lifespan of mats up to 40%.

The performance of outdoor rubber mats will improve through your installation and maintenance activities, which consider these particular factors. The setup uses advanced materials and modern methods to create a system that maintains high standards of quality while enduring various environmental challenges.

Maintenance of Rubber Playground Surfaces

Routine Cleaning and Care

The process of maintaining rubber playground surfaces requires regular cleaning, which includes cleaning activities that should take place to protect the playground surface from damage. The cleaning process requires workers to sweep the playground area at regular intervals to eliminate all trash, dirt and leaves, which will lead to surface damage over time. The Environmental Protection Agency (EPA) recommends the use of non-toxic, biodegradable cleaning agents because they protect the environment while maintaining surface cleanliness. The material receives effective cleaning through pressure washing, which removes deep-seated dirt and stains from areas that experience high foot traffic without causing any material harm.

Recent research demonstrates that playground surfaces that undergo bi-weekly cleaning procedures experience 25% fewer wear-and-tear issues than playgrounds that receive less frequent cleaning. The process of seasonal maintenance and snow removal during winter and heat reduction activities during summer helps to maintain their original condition. The Rubber Manufacturers Association (RMA) recommends that locations undergo regular inspections to detect cracks and warping, and uneven surfaces because these conditions pose safety hazards. The use of advanced cleaning techniques combined with expert cleaning schedules enables rubber surfaces to achieve an extended lifespan, which results in both financially viable and environmentally friendly outcomes.

Identifying and Repairing Damage

The proper maintenance of rubber surfaces requires organizations to establish a system that enables them to recognize and fix all types of damage. The information collected by industry experts indicates that rubber surfaces show maintenance problems with 25% of their surfaces needing repairs by their third year of usage for areas that experience high pedestrian traffic and face challenging environmental conditions. The three main problems that people face include cracking and discoloration, and loss of elasticity, which affect both the appearance and secure nature of the product.

Experts recommend utilizing specialized sealers and fillers that have been developed specifically for rubber materials to create effective solutions that solve these issues. The products that contain polyurethane or silicone compounds work effectively to fix damaged areas through their capability to fill cracks and restore area functionality. The development of infrared thermography techniques provides a current method that allows detectors to examine hidden structural damage that remains undetectable from the exterior.

Repair work requires execution at specific points according to the data analysis. The research indicates that performing maintenance work between 6 and 12 months after damage detection leads to maintenance cost reductions of up to 40% because early damage control stops all further material degeneration. Scheduled professional inspections of the property should occur at least once each year because this practice helps to identify small problems that would later escalate into major issues.

The use of advanced repair techniques together with established industry standards guarantees that rubber surfaces will continue to maintain their strength and security while remaining economical throughout their lifespan. The combination of modern technological solutions and a maintenance schedule gives organizations a powerful method to enhance equipment efficiency while minimizing operational costs.

Extending the Lifespan of Playground Mats

Proper maintenance, along with advanced maintenance techniques that include recent equipment serve as an essential requirement for playground mats to remain safe for use while operating effectively. The maintenance and installation practices of high-quality materials enable rubber surfaces to achieve a lifespan that extends between 10 and 15 years, according to recent maintenance reports. The key components of the system include two essential elements, which mandate all maintenance work to begin with regular cleaning operations that remove accumulated debris and surface demands for resurfacing to restore the surface to its original condition and the need to fix any visible cracks or damage without delay.

The 2023 playground safety study found that 35% of mat degradation happens because people fail to clean the area on a regular basis, while 25% of degradation occurs because of severe weather events. The application of protective coatings together with weather-resistant materials offers a solution to combat challenges such as UV degradation and water pooling, which guarantees product durability during difficult weather conditions.

The advancement of eco-friendly technologies, including recycled rubber and permeable designs, improves mat durability while contributing to sustainable practices. The latest industry reports demonstrate that these materials have a 40% lower environmental impact when compared to conventional materials which demonstrates their effectiveness in environmental conservation.

The use of these techniques, together with a scheduled maintenance program that includes two annual professional inspections, will enhance the durability of playground mats while reducing expenses that occur throughout the entire period.

Safety Standards and Certifications

Understanding ASTM and CPSC Guidelines

Playground mats achieve necessary safety standards together with required performance standards by complying with ASTM American Society for Testing and Materials standards and CPSC Consumer Product Safety Commission regulations. Open-air playground areas must meet ASTM standards, which include ASTM F1292, because the standards require playground surfaces to provide enough impact protection, which stops head injuries from happening. The testing of material shock absorption capacity determines its performance based on specific fall height distances which serve as essential testing standards.

The Public Playground Safety Handbook from CPSC mandates that playground surfaces must undergo testing procedures that prove their ability to protect against critical fall heights. The CPSC recommends that all playground designs require at least 6 inches of loose-fill wood chip or engineered wood fiber surfacing or 2 inches of rubber matting, which must follow specific design guidelines. The development of these guidelines results from extensive testing, which evaluates material safety and sustainability across different environmental conditions.

Recent studies from safety organizations and industry reports indicate that EPDM rubber surfacing materials achieve a resilience rate of up to 92% shock absorption, which establishes them as a top choice for impact reduction because they comply with both ASTM and CPSC standards. The 2022 market analysis shows that playground injuries decrease by 20% when safety-certified materials replace non-compliant materials.

Playground operators establish safe and durable playground systems by following these guidelines while they track new standard updates.

Importance of Compliance in Playground Safety

Playground safety standards require enforcement because they protect children from injuries that occur during playground use. The Centers for Disease Control and Prevention CDC reports that playground-related injuries send more than 200000 American children to emergency departments each year. The construction design and maintenance specifications of modern playgrounds receive protection through ASTM and CPSC guidelines because these standards establish which equipment should be built and maintained.

The design and equipment of playgrounds require strict compliance because current safety materials and design elements need these security measures. Studies show that impact-absorbing surfacing materials, including engineered wood fiber and rubber mats, can lessen fall-related injuries by up to 50% when compared to concrete and hard-packed surfaces. The National Recreation and Park Association NRPA stresses regular inspections because playgrounds that receive monthly safety checks experience 15-20% fewer accidents.

Playground operators create fun play environments that maximize safety by following established standards while incorporating new developments in durable, eco-friendly materials and advanced design solutions. The educational programs that maintain staff and stakeholders need ongoing development because they protect compliance, which helps to secure children’s long-term health.

Choosing Certified Rubber Playground Flooring

Designing a safe and accessible play environment requires incorporating certified rubber playground flooring elements into the design process. Rubber flooring functions as a preferred material because its shock-absorbing capabilities effectively decrease the chance of people getting injured during falls. National Program for Playground Safety research indicates that approximately 70% of playground injuries result from falls, which emphasizes the importance of implementing rubber flooring solutions as effective surface solutions.

The two most common surface types include rubber tiles and poured-in-place surfaces. The two surface types undergo testing to determine their ability to meet essential fall height requirements, which both ASTM International and CPSC standards have established. Certified poured rubber surfaces protect against impacts from heights up to 10 feet, which makes them more protective than other materials that include gravel and sand. The surfaces comply with ADA requirements, which create better access paths for children who face mobility barriers.

The current options for modern rubber flooring provide both safety and protection for the environment. Manufacturers use recycled rubber materials to produce tiles and rolls, which helps to decrease landfill waste while they create long-lasting surfaces that protect against weather conditions. The extended lifespan of rubber materials results in lower maintenance expenses throughout their operational life which makes rubber materials an economical choice for playground operators.

Rubber flooring provides flexible design options for play areas, which enables designers to create imaginative spaces through the use of bright colors and patterns. Using certified material from reputable suppliers ensures compliance with regulatory standards while promoting user safety. Playground operators should invest in rubber flooring because it helps them create inclusive, secure and sustainable environments for children of all abilities.

Reference Sources

-

Toxics Use Reduction Institute (TURI) – Playground Surfacing: Choosing Safer Materials for Children’s Health and the Environment

The research investigates how different playground surfacing materials affect human health and environmental health while proving rubber playground mats to be a safe and sustainable choice. The study reveals the chemical makeup of rubber materials and their safety measures.

Source: TURI Playground Surfacing Report -

Fairfield Market Research – Playground Surface Materials Market Report

The report examines the market expansion and industry patterns, and the way rubber playground surface materials are becoming established in the market. The report shows how public and private areas demand safe, long-lasting, and environmentally friendly playground surfaces.

Source: Fairfield Market Research Playground Surface Materials Market Report

Frequently Asked Questions (FAQs)

What makes rubber playground mats the ideal playground flooring option?

Rubber playground mats function as exceptional playground flooring materials because they create a safe environment while delivering permanent durability. The mats provide shock absorption, which enables them to protect users from injuries caused by falls. The construction materials of the item safeguard against both heavy usage and environmental impact and standard product deterioration throughout its entire lifespan. The product maintains its indoor and outdoor performance capabilities because its surface design prevents slipping under wet conditions.

Are rubber playground mats suitable for all weather conditions?

The answer is yes because rubber playground mats possess high adaptability, which allows them to function properly in all weather conditions. The materials are engineered to withstand both extreme temperature conditions and heavy rainfall and ultraviolet radiation exposure. The material prevents water accumulation because of its water-resistant characteristics, which protect against safety hazards. The playgrounds maintain operational safety throughout the entire year because the durable equipment withstands various weather conditions.

Can rubber flooring be customized for different playground designs?

Absolutely! Rubber flooring provides high flexibility because it enables different design options, which let spaces create their own unique visual appeal and operational functionality. The design allows for various artistic elements through different color options and pattern choices, and thickness variations, which create designs that promote creative play while maintaining safety standards and industry regulations. The customization options enable customers to select from two options: traditional black rubber mats and vibrant interlocking tiles which offer nearly limitless selection possibilities.

How does rubber flooring promote sustainability in playgrounds?

Rubber flooring supports sustainability initiatives because it consists of recycled materials which include repurposed rubber tires. The process reduces waste while decreasing the environmental impact associated with constructing playgrounds. The mats maintain their original condition for extended periods, which reduces replacement needs, making them an environmentally sustainable solution for permanent applications.

Is there any maintenance required for rubber playground mats?

The process of maintaining rubber playground mats requires simple steps that do not incur high expenses. The flooring maintains its excellent quality through regular maintenance, which involves cleaning the surface with water and mild soap. The procedure requires regular inspections to monitor both the product condition and the level of wear to maintain operational safety. The product’s strong construction decreases the need for extensive maintenance work, which results in both time and cost savings throughout its entire usage period.

Where can I purchase certified rubber playground mats?

Reputable suppliers provide certified rubber playground mats for sale because they maintain safety and quality standards. Playground safety requires choosing suppliers who provide certified products that meet industry standards for safety and product durability. The suppliers present detailed product information along with installation support to assist customers during their product selection and installation process.