Rubber tiles establish exceptional flooring solutions that deliver both strength and flexible performance and reliable operation for gyms, playgrounds, residential workout spaces, and multiple other environments. Rubber flooring delivers essential functions that enable it to construct high-impact exercise spaces and develop secure play areas. The ultimate guide will provide complete information about rubber tiles, which includes their benefits and applications, and essential factors to consider when selecting the appropriate tile for your requirements. The post will establish why rubber flooring serves as the preferred flooring option for both home and business environments.

Understanding Rubber Tiles

What are Rubber Tiles?

The manufacturing process of rubber tiles produces flexible flooring solutions that manufacturers create from natural rubber and synthetic rubber materials. The products come in multiple dimensions, which include different thicknesses and a range of color options and surface patterns, thus making them appropriate for multiple purposes. Rubber tiles remain the preferred flooring choice for homes and businesses because they combine outstanding strength with slip resistance and impact protection. The tiles which people commonly use in gyms, playgrounds, garages and kitchens deliver both protective features and user-friendly design elements.

The global rubber flooring market will achieve a 6.4% compound annual growth rate (CAGR) from 2023 to 2030, which results from increasing demand for sustainable, environmentally friendly building materials, according to recent research. Many rubber tiles are produced from recycled materials, which include old tires, thus making them an environmentally friendly option. The products became popular with users who needed protection in high-traffic areas because they could withstand both water and heat while resisting major damage.

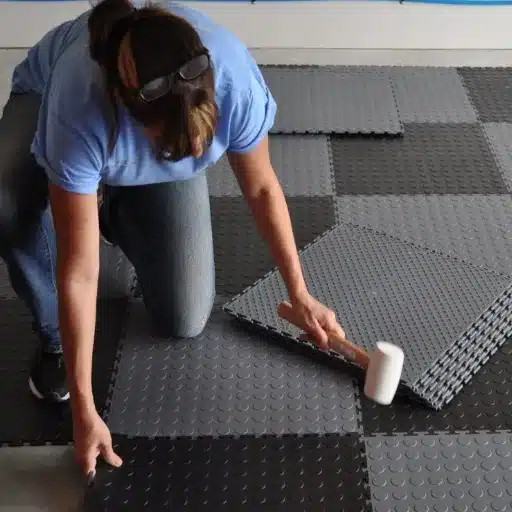

Rubber tiles use interlocking or adhesive systems for installation, which makes installation simple because their designs enable secure fitting into any area. The products provide protection against sound, which serves as a vital requirement for spaces that include gyms and residential buildings. Rubber tiles meet users’ practical needs while supporting environmentally friendly practices through their contemporary design elements.

Types of Rubber Flooring Tiles

People can select from different types of rubber flooring tiles that meet their particular requirements and special needs. The most common types of products available are listed below.

- Interlocking Rubber Tiles

People choose interlocking tiles because they offer simple installation methods and multiple usage possibilities. The tiles connect through puzzle-like edges, which create secure connections that do not require glue for assembly. These tiles are an excellent choice for DIY projects, like home gyms or playrooms. The recent market research shows that interlocking tiles make up about 40 percent of rubber flooring products, which people buy for their homes, thus proving their broad popularity. - Recycled Rubber Tiles

Recycled rubber tiles function as sustainable flooring materials because their main component consists of used tires. The products deliver long-lasting performance at affordable rates while enabling customers to choose from various design alternatives. The production process supports environmental sustainability because it employs waste materials and research indicates that more than 90 percent of new rubber flooring products contain recycled materials. - Vulcanized Rubber Tiles

Vulcanized rubber tiles display a design that withstands intense use while offering excellent protection against destruction. The materials find widespread use in commercial settings, which include industrial plants, fitness centers, and healthcare centers. Data shows that these tiles maintain their operational performance for more than two decades when used in areas with high foot traffic, which makes them a financially wise choice because of their extended lifespan. - Textured and Smooth Rubber Tiles

Textured tiles serve as essential components for swimming pool decks and locker room areas because they provide extra grip, which prevents slips. Retail businesses and office spaces utilize smooth tiles to establish a modern look that their customers find attractive.

Research highlights that the global rubber flooring market is expected to grow at a compound annual growth rate (CAGR) of about 5.6% from 2023 to 2030. The growth trend results from two main factors, which include rising demand for environmentally friendly construction materials and the global growth of fitness centers and business facilities.

Benefits of Using Rubber Flooring

Rubber flooring provides multiple advantages, which make it a preferred flooring option for both commercial and residential spaces. The material has gained popularity because its two main features, durability and minimal upkeep needs, make it practical for various uses, according to recent data. The non-slip properties of rubber flooring provide improved safety, which becomes especially important in high-traffic areas that include gyms and hospitals. The material provides high protection against water and stains, and impact damage, which decreases the need for upkeep.

Current market trends show an increasing demand for eco-friendly building materials because rubber flooring products often use recycled content, which attracts environmentally conscious buyers. Statista reports that in 202,2 more than 25% of rubber flooring products sold globally were made from recycled rubber, a trend expected to continue growing. The green building industry will receive higher funding, which will increase rubber flooring as an eco-friendly and flexible flooring option that will reach a market size of $10 billion by 2030.

Applications of Rubber Tiles

Rubber Tiles for Gyms

The gyms now use rubber tiles as their standard flooring because the tiles sustain constant use while protecting against slips and structural damage. The flooring material is built to withstand extreme impact, which makes it appropriate for weightlifting areas, cardio sections, and functional training spaces. The Grand View Research report shows that the global gym flooring market reached a value of $1.37 billion in 2021 and will experience a 5.2% annual growth rate from 2022 until 2030 because rubber tiles will drive market expansion. The material becomes the first choice for gym owners because it provides reduced sound levels and high grip strength and helps safeguard users from workout-related injuries.

The current sustainable trends in fitness facilities have led to gyms adopting modern rubber tiles, which contain recycled materials. The interlocking design system enables installers to complete their work quickly, and the new manufacturing method offers products that provide better odor protection and visual design options. The combination of these elements establishes rubber tiles as the top choice for gym flooring because they deliver functional benefits and secure safety and environmental sustainability.

Residential Uses of Rubber Flooring

Homeowners are selecting rubber flooring as their preferred flooring material because it provides both design flexibility and long-lasting performance, and needs minimal upkeep. Homeowners now use rubber flooring throughout their homes because they want to install it in kitchens, playrooms, basements, and home gyms. The global rubber flooring market will be valued at $2.7 billion in 2028, according to recent research, which shows that the market will expand at a 5.2% compound annual growth rate between 2023 and 2028 due to rising demand in both commercial and residential markets.

Rubber flooring offers a significant benefit because it effectively reduces noise, which makes it suitable for homes that have young children and pets. The rubber flooring material demonstrates stain and moisture resistance, which makes it suitable for spaces that experience spills or high humidity conditions. Homeowners can now use design innovations to select from multiple color options and texture choices, and pattern designs, which create modern interior design looks. The residential rubber flooring products have shifted toward eco-friendly manufacturing methods which demonstrate how sustainability has become essential in home improvement trends.

Modern homeowners can achieve their ideal home environment through rubber flooring because it offers essential features needed to meet their functional needs while maintaining aesthetic appeal and environmental conservation.

Custom Colors and Design Options

Homeowners who use rubber flooring can choose their preferred colors and design options, which allow them to create their ideal home design based on various residential design styles. The latest research shows that manufacturers now offer advanced flooring customization tools, which enable homeowners to create their specific flooring design needs. Users can now create their own flooring color combination through custom color-matching services, which allow them to match their flooring to their wall paints and furniture, and complete home design.

Patterned rubber flooring has become a fashionable flooring choice since it gained popularity during the past two years. Modern homeowners choose geometric patterns, marble designs, and complex surface textures as their primary design elements. More than 40% of consumers currently choose these decorative elements based on 2023 industry research because they want to enhance the character and elegance of their home interiors. The production process now supports high-definition design printing, which produces highly detailed wood and stone effects that combine visual appeal and rubber flooring.

The current manufacturing methods include anti-fading technology, which enables users to maintain their color brightness for extended periods despite experiencing heavy foot traffic or direct sunlight exposure. Seventy percent of modern rubber flooring products contain recycled or renewable content, which supports sustainability while meeting the global demand for eco-friendly home improvement solutions.

Homeowners can achieve a perfect combination of functionality, durability, and style because of these advanced technological solutions.

Installation Methods for Rubber Flooring

Interlocking Rubber Tiles Installation

The installation process for interlocking rubber tiles has become popular among residential and commercial spaces because these tiles provide both a quick setup and many different ways to use them. The tiles include edges that use a puzzle-style snapping system to connect, which allows for installation without needing any adhesives or special tools. The recent sales data show that interlocking tiles represent approximately 40 percent of the total rubber flooring market, which demonstrates their widespread popularity.

The installation process starts with the subfloor preparation, which requires a clean, dry, and level surface. After the preparation process completes, the tiles should be installed from one room corner while moving toward the other room corner. The process requires edge measurements and trims to achieve precise edge alignment. Interlocking tiles provide a major advantage because users can reuse them and move them to different locations, which enhances their value. The temporary nature of these setups makes them suitable for both home use and spaces that experience regular layout changes.

The tiles offer straightforward installation methods that result in durable products that can withstand heavy use for a duration of 10 to 20 years. The current market shows that 75 percent of interlocking rubber tiles in stock today are produced from recycled materials, which demonstrates their strong commitment to environmental protection. Interlocking rubber tiles serve as a practical flooring option because they meet multiple requirements through their functional design and sustainable construction, and design adaptability.

Glue-Down vs. Floating Installation

The choice between glue-down and floating installation methods for interlocking rubber tiles depends on three factors which include usage needs and financial constraints and expected product lifespan. The stability of glue-down installations makes them appropriate for installation in commercial spaces that experience heavy foot traffic. Experts in the industry project that proper glue-down maintenance procedures will extend the lifespan of these installations beyond two decades. The method requires extensive labor because workers must apply adhesive materials, which may produce volatile organic compound emissions based on the adhesive quality.

The floating installations provide an easy-to-use installation solution that appeals to DIY enthusiasts who want to handle their own home projects. These spaces work best in residential buildings and areas that need to change their layout throughout the day l,ike gyms and playrooms. The floating system enables tile connections through locking mechanisms, which eliminate the need for adhesive use, resulting in reduced VOC emissions and improved environmental performance. The research findings demonstrate that floating installations maintain their protective capability for a period of 10 to 15 years while offering users easy installation access. The development of modern floating interlocking tiles now provides users with textured surface options in addition to advanced locking systems, which deliver enhanced protection against movement.

The process of making an informed selection requires you to analyze the advantages and disadvantages of different methods, together with your precise requirements for the particular project.

Preparation and Tools Needed for Installation

The first step to achieve effective floating interlocking tile installation requires proper tool and material collection. The current findings explain that the construction area needs thorough cleaning to achieve optimal tile stability and durability, which requires complete debris removal. The research indicates that a level surface represents an essential requirement for proper installation, while any uneven surfaces must undergo treatment through the application of leveling compound or underlayment.

The installation process requires you to bring three essential tools, which include a rubber mallet and a utility knife for making adjustments and a tape measure for achieving precise measurements. Most current interlocking tile systems use self-aligning edge technology, but users can achieve better results through the application of straight edges or chalk lines to maintain their chosen spacing throughout the entire process. Manufacturers today supply eco-friendly materials through most floating tile products, which leads to reduced carbon emissions and improved product strength. The application of these new technologies allows designers to achieve sustainable installation processes that enable efficient installation work, which needs only 15-20 years of daily wear protection due to advanced construction techniques.

Pros and Cons of Rubber Flooring

Advantages of Rubber Tiles

Rubber flooring provides three benefits, which include its damage resistance and its ability to function in various ways, and its need for basic maintenance. The main benefit of the material protects it from harm because rubber tiles maintain their original condition for more than two decades when users maintain them properly. The product delivers outstanding value for use in high-traffic areas, which include gyms, schools, and commercial buildings. The rubber tiles create a comfortable environment because their built-in shock absorption system reduces noise levels, which makes them suitable for spaces that require strict sound management.

The modern rubber tiles provide users with their main benefit because the tiles use environmentally friendly methods. The modern tile production process allows manufacturers to create products that use 100% recycled rubber materials, which include repurposed tires, to decrease waste and support sustainable development. The latest research shows that using recycled rubber for flooring purposes results in substantial reductions of both raw materials and energy usage, which supports global environmental protection initiatives.

The product increases its value through practical benefits because rubber tiles protect against water damage and sliding accidents while their surface maintains its ease of care across various usage conditions. The current manufacturing process enables rubber flooring to exist in multiple colors and textures, which allows consumers to choose their preferred design without losing functional ability. Rubber tiles provide customers with sustainable flooring options that offer excellent performance because of their extended lifespan and environmentally friendly characteristics.

Potential Drawbacks to Consider

The users of rubber flooring receive multiple advantages from the product yet they need to examine its three potential drawbacks. The primary issue relates to the total expenses needed for implementation. The price of high-grade rubber flooring starts at $3 per square foot and extends up to $12 per square foot with the final cost depending on the specific product category and design. The total cost needed to start this project exceeds the initial investment required for standard flooring materials.

The product shows two main weaknesses that need evaluation because it needs evidence. The product shows two main weaknesses that need evaluation because it needs evidence. The material shows two main weaknesses that need evaluation because it needs evidence. The material produces a strong odor which requires several weeks to fully disappear after initial detection.

The product shows two main weaknesses that need evaluation because it needs evidence. The product shows two main weaknesses that need evaluation because it needs evidence. The product shows two main weaknesses that need evaluation because it needs evidence. People need to check both certification marks and manufacturer details to confirm suthe stainability of their products.

Durability and Maintenance of Rubber Flooring

Rubber flooring serves as an excellent option for residential and commercial spaces that experience continuous foot traffic because of its outstanding strength. The research study results show that high-grade rubber flooring materials can endure for 20 years, provided that proper installation of thick materials takes place. Natural resistance processes offer complete protection against all damage types, which include wear and tear, scratches, and dents.

The process to clean rubber flooring needs only a few steps, which makes it easier to maintain compared to other types of flooring. The standard cleaning process requires users to perform regular sweeping tasks and damp mopping tasks with a pH-neutral cleaner for surface maintenance purposes. Rubber flooring functions as a non-porous material that provides built-in protection against water and stain damage, thus preventing spills from forming any material damage. The research data shows that using recycled rubber or vulcanized rubber for flooring purposes will enhance both the stain protection and the product lifespan.

The material demonstrates its ability to carry heavy loads because it maintains its original shape under pressure. The rubber flooring solution used in gym facilities and commercial areas demonstrates its ability to handle heavy loads during both equipment use and foot traffic. The material displays tensile strength properties that range between 5 and 15 MPa (megapascals), which depend on the specific grade or formulation. The product makes rubber flooring a practical option for various locations that require long-lasting materials.

Rubber flooring provides excellent durability with minimal maintenance needs, which creates a practical solution for customers who care about both environmental issues and cost savings.

Maintenance Tips for Rubber Tiles

Cleaning and Care for Longevity

The correct maintenance procedures for rubber tiles will double their lifespan while maintaining their original appearance and functional capabilities. The initial step for rubber tile cleaning requires standard sweeping or vacuuming methods which will remove dirt and debris because these materials create abrasions through their continuous presence. The combination of a damp mop and pH-neutral cleaners achieves the best results for deep cleaning purposes. The material will sustain damage through operational use when people apply harsh chemicals which include bleach and acidic cleaners. Recent cleaning guidelines recommend a pH solution that ranges from 6 to 8 because it preserves the rubber flooring system.

Organizations should establish a cleaning schedule that requires them to conduct deep cleaning work two times each week by using low-speed cleaning equipment that includes soft brush attachments to remove hidden dirt. Data shows that floors cleaned with appropriate equipment tend to last 25% longer than those cleaned manually or with harsh chemicals. The yearly sealing process for rubber tiles provides protection against stains and enhances their resistance to damage. The complete maintenance of dry conditions functions as the only method to protect the flooring system because continuous moisture leads to adhesive failures and mold development.

Common Issues and Solutions

- Cracking or Damage to Rubber Tiles

People who walk on rubber tiles too much and people who stop doing their regular maintenance work cause cracks and other damage to the tiles. Research has found that placing furniture pads beneath heavy objects and distributing weight across the entire area helps to minimize these issues. Research demonstrates that locations that use pads throughout their operations achieve a 30% decrease in visible damage after three years when compared with locations that operate without pad protection. The application of a professional-grade rubber repair kit to repair cracks provides immediate protection against future material deterioration. - Loss of Adhesion

Two factors, which include extended moisture exposure and incorrect adhesive application lead to decreased bonding strength between rubber tiles and their subfloor. The installation process benefits from moisture barrier installation because it extends adhesive functionality by 40% according to industry research. The process needs regular inspections to maintain proper drying in wet environments that include gym lockers and kitchens. When adhesive failure happens, users should apply a new adhesive that has better moisture protection capabilities. - Staining on Rubber Tiles

Rubber tiles develop stains when spills, oils, and strong cleaning agents come into contact with them. Research from cleaning product manufacturers highlights that pH-neutral cleaners are the most effective at removing stains without deteriorating the material. Regular cleaning with these products decreases tile staining by half over time, which helps to avoid permanent tile damage. - Discoloration from UV Exposure

Outdoor rubber tiles experience color fading because of sunlight exposure, which particularly affects their outdoor applications. The combination of UV-resistant coatings with modern treatment methods protects against UV radiation, which exceeds the capabilities of standard coatings by 60%. The installation of shades and protective covers in areas that face direct sunlight helps to decrease discoloration effects.

Rubber flooring systems achieve both extended lifespan and improved condition through two methods, which involve regular maintenance and the application of scientifically validated contemporary products.

When to Replace Your Rubber Flooring

Rubber flooring design achieves its purpose through materials that endure their entire expected lifespan because all materials eventually reach their endpoint. The optimum time for replacement must be determined because it impacts both operational capacity and protective measures. The lifespan of rubber flooring ranges from 10 years to 20 years because its durability depends on material quality, foot traffic and upkeep procedures. High-quality rubber flooring maintains its performance for 20 years in low-traffic areas, but gyms and commercial spaces must replace their flooring after 10 years of service.

Rubber flooring replacement becomes necessary when visible damage shows through cracks and tears, and permanent stains remain after professional cleaning attempts. The removal of elasticity from the flooring materials creates safety hazards because the material no longer delivers the rubber safety features of cushioning and slip resistance. Mold growth or persistent odors that remain after cleaning procedures indicate a problem that requires special attention in moisture-sensitive areas such as locker rooms and kitchens.

According to recent data, 30% of gym owners need to replace their flooring every 7 to 10 years because of heavy usage, while residential rubber flooring can last longer with proper maintenance. The implementation of flooring technology advancements, which include antimicrobial treatments and UV-resistant coatings, will extend the lifespan of rubber flooring. Your team needs to spend time fixing multiple floor sections because organized patching work results in higher costs than total floor replacement.

You need to assess your rubber flooring condition through regular checks while evaluating these elements to determine the optimal replacement time, which will maintain safety standards, visual appeal, and functional capacity.

Reference Sources

-

Rubber tiles made from secondary raw materials with immobilized titanium dioxide as passive air protection – This research focuses on the use of recycled materials in rubber tiles and their environmental benefits.

-

The Role of TiO2 during the Accelerated Aging of Recycled Rubber Tiles – This paper examines the durability and aging process of recycled rubber tiles, particularly for playgrounds and sports fields.

Frequently Asked Questions (FAQs)

What advantages do rubber tiles bring to gym flooring systems?

Gym facilities prefer rubber tiles for their flooring needs because these tiles deliver three key advantages, which include long-lasting durability and the ability to absorb shocks and provide protection against slipping hazards. The surface creates a secure environment that enables athletes to perform their exercises while the system protects against injuries through its weight training safety measures and high-energy motion defense capabilities. The rubber flooring system operates as a sound-absorbing material, which decreases noise levels while its maintenance needs require only periodic cleaning and basic upkeep procedures.

What level of durability do rubber tiles possess when compared to other types of flooring materials?

Rubber tiles stand as one of the most resilient flooring materials, which function effectively in high-traffic environments found in gyms, playrooms, and commercial facilities. The material exhibits protection against scratches, and dent, and abrasions while it maintains its structural integrity under the extreme weight of gym equipment. The rubber tiles maintain their performance throughout multiple years of use, which results in outstanding value for customers.

Do rubber tiles have an environmentally friendly nature?

Yes, many rubber tiles are made from recycled materials, such as recycled tires, making them an environmentally sustainable option. The eco-friendly rubber flooring system, which helps minimize waste production, creates a sustainable solution. The manufacturing companies produce recyclable products that consumers can dispose of after they finish using them, which helps advance environmentally friendly practices.

Do rubber tiles have installation possibilities beyond gym facilities?

Rubber tiles demonstrate their flexibility because they can be used in multiple locations, which include residential home offices and kitchen spaces, playroom areas, and outdoor locations. The product provides essential support for areas that need a surface that will endure heavy use while offering protection against slips and absorbing impact forces. The range of colors and designs of rubber tiles enables users to select products that match their specific style requirements.

What steps should people follow to clean and care for rubber flooring surfaces?

Rubber flooring maintenance requires no special training because it remains simple and easy to accomplish. Users need to complete two main steps because they must first perform regular sweeping or vacuuming to eliminate dirt before using a mild detergent solution for mopping service. The material requires protection from all harsh chemical substances, plus solvents that have the potential to cause damage. The rubber floor cleaners provide deep cleaning solutions that protect tile lifespan while maintaining their original quality.

Do rubber tiles offer sufficient protection against slipping hazards?

Rubber tiles deliver slip-resistant surfaces that function as safe solutions for places that experience high foot traffic and water and sweat activities, which take place in gyms and bathrooms. Some rubber tiles feature textured surfaces for enhanced grip, providing added safety even in wet conditions. The product serves as the perfect selection for both residential environments and business facilities, which have established safety as their main priority.