When it comes to selecting the ideal geomembrane liner for a specific project, two of the most commonly compared options are HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride). Both materials are widely used across industries like construction, agriculture, and waste management due to their ability to provide durable and long-lasting containment solutions. However, the choice between HDPE and PVC can significantly impact the performance, cost, and sustainability of a project. This blog post dives deep into the key distinctions between these two geomembranes, helping you make an informed decision based on your specific application needs. Whether you’re focused on environmental compatibility, flexibility, or cost-effectiveness, understanding these differences is critical to maximizing the success of your project. Stay tuned as we uncover the advantages, limitations, and best use cases for each type, empowering you to choose the most suitable liner with confidence.

What is a PVC Geomembrane and How is it Used?

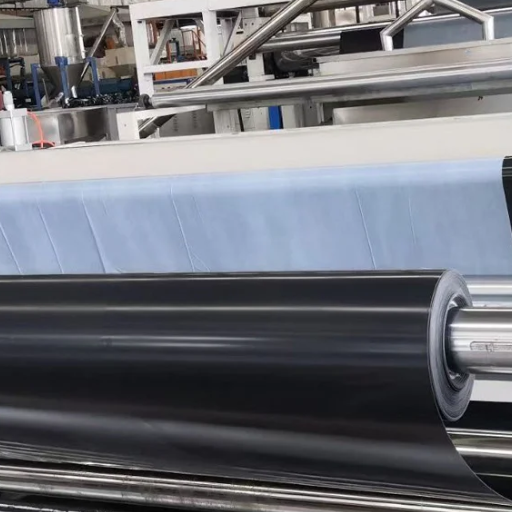

A PVC geomembrane, or polyvinyl chloride geomembrane, is a type of synthetic liner widely used in various industries for containment and barrier applications. Known for its flexibility and durability, PVC geomembranes are effectively employed to prevent the leakage of liquids or gases in projects such as wastewater treatment ponds, landfills, and mining operations. Their ease of installation and adaptability to uneven surfaces make them a practical choice, particularly in environments that demand reliable, long-lasting containment systems.

Characteristics of PVC Geomembranes

PVC geomembranes exhibit a range of characteristics that make them an ideal choice for demanding containment applications:

- High Flexibility and Elasticity

PVC geomembranes are highly flexible, allowing them to conform easily to uneven or irregular surfaces. This flexibility minimizes stress points and enhances performance in areas with significant movement, such as seismic zones or settling foundations.

- Durability and Weather Resistance

Designed for long-term applications, PVC geomembranes demonstrate excellent resistance to weathering, UV radiation, and temperature fluctuations. This makes them suitable for both exposed and buried installations without significant degradation over time. Their average service life can range from 20 to 30 years when correctly installed and maintained.

- Low Permeability

The impermeable nature of PVC geomembranes ensures minimal leakage, effectively containing liquids or gases. Their permeability rate is exceptionally low, often measured at less than 1 x 10^-10 cm/s, making them reliable in safeguarding against environmental contamination.

- Ease of Installation

Due to their lighter weight in comparison to other types of geomembranes, PVC sheets are easier to transport, handle, and install. The material can be heat-welded or seamed on-site, ensuring strong and watertight joins. This simplifies construction timelines and reduces labor costs.

- Chemical Resistance

PVC geomembranes are highly resistant to a variety of chemicals, which is crucial for projects like landfill liners or industrial wastewater containment. They tolerate exposure to acids, alkaline substances, and hydrocarbons without compromising structural integrity.

- Environmental Compatibility

Modern innovations in PVC production have focused on reducing environmental impact. PVC geomembranes are recyclable and can be manufactured with reduced plasticizer content, contributing to sustainability while maintaining performance.

- Cost-Effectiveness

With their durability, ease of installation, and low maintenance requirements, PVC geomembranes provide a cost-effective solution for long-term containment needs. Their life-cycle costs are competitive when compared to other materials, ensuring value for infrastructure projects.

These characteristics make PVC geomembranes a versatile and reliable choice for a wide array of industrial and environmental applications, pushing the boundaries of modern containment technology.

Common Applications for PVC Geomembrane Liners

PVC geomembrane liners are extensively used across various industries for their proven durability, chemical resistance, and adaptability. Below are some of the most common applications:

- Landfill Liners and Caps

PVC geomembranes are widely used in landfill projects to prevent harmful leachate from contaminating surrounding soil and groundwater. Studies have demonstrated their longevity in withstanding exposure to hazardous substances while maintaining low permeability, ensuring effective containment over decades.

- Mining Operations

Mining industries utilize PVC liners in tailings ponds, heap leach pads, and evaporation ponds because of their chemical resistance to acidic and alkaline solutions. For example, modern heap leaching processes rely on PVC’s ability to handle aggressive chemicals while maximizing the recovery of valuable minerals.

- Water and Wastewater Containment

These liners are an excellent choice for reservoirs, sewage treatment plants, and stormwater retention systems. PVC’s flexibility allows it to accommodate movement or settlement in the underlying ground, reducing the risk of leaks. Additionally, they can handle exposure to UV radiation and fluctuating temperatures, critical for outdoor applications.

- Agricultural Ponds and Irrigation Canals

Agriculture benefits significantly from PVC geomembranes in irrigation canals and farm ponds, where water conservation is vital. The material’s impermeability ensures efficient water storage and distribution, essential for managing agricultural resources, particularly in regions prone to drought.

- Tunnel Waterproofing

Tunnels, such as subway systems or mountain passageways, rely on PVC liners to maintain structural integrity against water ingress. PVC geomembranes achieve this by offering superior flexibility and weldability, key features for ensuring complete waterproofing under high pressure and difficult installation conditions.

- Environmental Protection Projects

From artificial lakes to wetlands restoration, PVC geomembranes are instrumental in environmental conservation initiatives. Their ability to provide a dependable barrier helps ensure sensitive ecosystems remain undisturbed from external pollutants.

Advantages and Disadvantages of PVC Geomembrane

Advantages:

- High Flexibility and Durability

PVC geomembranes are known for their excellent flexibility, allowing them to adapt to uneven surfaces and intricate shapes without compromising their integrity. This makes them ideal for a wide range of applications, from lining reservoirs to landfill capping. Additionally, their high durability ensures long-lasting performance under various environmental conditions.

- Superior Chemical Resistance

These geomembranes exhibit excellent resistance to a wide array of chemicals, including acids, alkalis, and industrial solvents. This feature makes them particularly effective in environments where chemical exposure is prevalent, such as mining, wastewater treatment, and industrial storage facilities.

- Ease of Installation

PVC geomembranes are lightweight and easy to transport, which can significantly reduce installation costs. Their weldability ensures strong, leak-proof seams, even under challenging conditions, such as steep slopes or irregular terrain.

- Cost-Effective Solution

Compared to other geomembrane materials, PVC provides an economical balance of performance and cost. This makes it a preferred choice for large-scale projects with budget constraints.

- Environmental Resilience

These geomembranes are not only waterproof but also resistant to UV radiation and weathering when protected properly, ensuring reliable performance in outdoor applications.

- Recyclability

PVC geomembrane materials can often be recycled, contributing to sustainable construction practices and reducing overall environmental impact.

Disadvantages:

- Limited Heat Resistance

PVC geomembranes may become less effective in extreme heat conditions, as high temperatures can lead to material deformation or loss of tensile strength over time.

- Potential for Plasticizer Loss

Over time, the plasticizers used to provide flexibility in PVC geomembranes may leach out, potentially leading to brittleness and reduced lifespan in aggressive environments.

- Environmental Concerns

The production process of PVC involves chlorine and other chemicals, raising concerns about its environmental footprint. Additionally, improper disposal of PVC geomembranes can impact ecosystems.

- Susceptibility to Punctures

Although durable, PVC membranes can be vulnerable to sharp objects or abrasive materials, making puncture resistance a consideration in specific installations.

- Maintenance Requirements

Depending on the application, PVC geomembranes may require regular monitoring and maintenance to ensure continued effectiveness, particularly in environments with volatile or heavy load-bearing conditions.

By weighing these advantages and disadvantages, project planners can make informed decisions about the suitability of PVC geomembranes for their specific needs. Each project’s requirements, budget, and environmental considerations must be carefully evaluated to optimize overall performance.Exploring the Features of HDPE Geomembrane

Exploring the Features of HDPE Geomembrane

High-Density Polyethylene (HDPE) geomembrane is a highly durable and versatile material widely used in containment and environmental protection applications. Renowned for its exceptional chemical resistance, HDPE geomembrane effectively prevents contamination from hazardous liquids and corrosive substances. Its impermeability ensures that water and other fluids are securely contained, making it ideal for use in landfills, mining operations, and wastewater treatment facilities.

HDPE geomembrane is also valued for its strength and durability, which allow it to withstand extreme environmental conditions, including temperature fluctuations and UV exposure. Additionally, it is environmentally friendly, as it can be recycled and has a long lifespan, reducing waste over time. These features make HDPE geomembrane a reliable and sustainable choice for various infrastructure and environmental projects.

Properties of HDPE Geomembranes

High-Density Polyethylene (HDPE) geomembranes stand out as a reliable and versatile solution for various containment and lining applications. Their properties make them a preferred choice in industries such as waste management, mining, and water conservation. Below are the key properties of HDPE geomembranes:

- Exceptional Chemical Resistance

HDPE geomembranes exhibit superior resistance to a wide range of chemicals, including acids, alkalis, and hydrocarbons. This makes them ideal for use in hazardous waste containment systems and industrial applications.

- Durability and Longevity

Known for their high durability, HDPE geomembranes can withstand harsh environmental conditions, including UV radiation, extreme temperatures, and mechanical stress. Studies indicate that under proper installation and maintenance, HDPE liners can have a lifespan of over 30 years.

- Low Permeability

One of the standout features of HDPE geomembranes is their extremely low permeability. Their ability to prevent the passage of liquids and gases ensures effective containment, crucial for applications such as landfill liners and wastewater treatment plants.

- High Tensile Strength

HDPE geomembranes have a high tensile strength, capable of enduring significant stress without tearing or deformation. This characteristic is particularly valuable in applications involving heavy loads or uneven foundations.

- Temperature Stability

HDPE geomembranes perform reliably within a wide temperature range, typically from -40°F to 176°F (-40°C to 80°C). This makes them suitable for diverse climates and challenging operational conditions.

- Environmental Safety

Free from harmful additives, HDPE geomembranes are considered safe for projects requiring environmental stewardship, such as potable water storage and agricultural pond liners.

- Ease of Installation

HDPE sheets can be heat-welded for secure, leak-proof joints, reducing the risk of seepage. Their flexibility allows them to adapt to varying project contours effectively during installation.

These properties highlight why HDPE geomembranes are a highly recommended option for projects demanding robust, long-term solutions. By combining their outstanding mechanical and chemical qualities with proven reliability, HDPE geomembranes continue to drive advancements in containment technology.

Uses and Applications of HDPE Geomembrane Liners

HDPE geomembrane liners are utilized across a range of industries due to their exceptional durability, chemical resistance, and impermeability. Below are some of the key applications, along with detailed insights into their benefits:

1. Landfills and Waste Containment

One of the primary uses of HDPE geomembrane liners is in landfills, where they act as a critical barrier to prevent leachate from contaminating surrounding soil and groundwater. Modern landfill designs incorporate multi-layer composite liners, including HDPE, as part of their containment systems. Studies reveal that HDPE liners can have a service life exceeding 100 years under optimal conditions, making them an essential component in long-term waste management solutions.

2. Mining Operations

Mining projects frequently rely on HDPE geomembranes for heap leach pads, tailings ponds, and secondary containment areas. Their high resistance to aggressive chemicals, such as acids and cyanides, makes them an ideal choice for handling mining byproducts. The liners are engineered to withstand heavy loads and fluctuating temperatures commonly encountered in mining settings, ensuring environmental protection while promoting operational efficiency.

3. Water and Wastewater Treatment

HDPE liners are extensively applied in water reservoirs, canals, and wastewater treatment plants. Their low water permeability and ability to withstand UV exposure ensure long-term performance in exposed environments. For large-scale reservoir projects, liners have been reported to save millions of gallons of water by significantly reducing seepage loss over time.

4. Agriculture and Aquaculture

HDPE geomembranes are widely employed in agriculture for irrigation ponds, canals, and lagoon lining. Farmers benefit from their cost-effective ability to minimize water loss and safeguard water quality. Similarly, in aquaculture, these liners provide a safe environment for fish and shrimp farming by resisting contaminants, simplifying cleaning, and extending operational lifespan.

5. Oil and Gas Industry

Spill containment systems in oil and gas operations, including brine ponds and tank farms, frequently rely on HDPE geomembranes. Their robust resistance to hydrocarbons ensures that hazardous substances are securely contained, adhering to strict environmental compliance standards. Furthermore, HDPE liners can endure the extreme conditions characteristic of oilfield sites.

6. Erosion Control

Used in slope stabilization and erosion control applications, HDPE liners play a crucial role in preventing soil erosion, particularly along riverbanks and steep inclines. Their strength and flexibility allow engineers to stabilize these areas effectively, even under harsh environmental conditions.

Benefits and Drawbacks of HDPE Geomembrane

Benefits

- High Chemical Resistance

HDPE geomembranes are renowned for their excellent resistance to an extensive range of chemicals, including acids, bases, and organic solvents. This characteristic makes them ideal for containment applications in mining, landfill, and industrial storage, where exposure to hazardous substances is common. Their chemical inertness ensures long-term stability and minimizes the risk of contamination.

- Durability and Longevity

With superior tensile strength and resistance to UV degradation, HDPE geomembranes can withstand extreme weather conditions and mechanical stresses. Field data highlights their life expectancy of over 30 years when properly installed and maintained, making them a cost-effective solution for long-term projects.

- Environmental Sustainability

HDPE liners are highly sustainable as they are manufactured using recyclable materials and reduce the risk of leakage into surrounding environments. By providing effective containment, they help industries meet stringent environmental regulations while also protecting ecosystems.

- Waterproofing Capabilities

HDPE geomembranes exhibit excellent impermeability, ensuring effective waterproofing for applications like reservoirs, ponds, and canals. Tests have shown their water permeability rate to be significantly lower than other materials, ensuring minimal seepage over time.

- Cost Efficiency

While the upfront cost of HDPE geomembranes may vary depending on thickness and customization, their overall economic viability is reinforced by minimal maintenance requirements, reduced repair expenses, and extended service life. Case studies show substantial cost savings in large-scale engineering projects.

Drawbacks

- Installation Challenges

The installation process for HDPE geomembranes requires specialized welding techniques to ensure seamless joints, which demand skilled labor and proper equipment. Errors during installation can compromise the liner’s integrity, leading to potential long-term issues.

- Limited Flexibility in Extreme Cold

HDPE geomembranes can become less flexible and more brittle at very low temperatures, making them susceptible to cracking under mechanical stress. This limitation necessitates careful consideration in regions with harsh cold climates.

- Prone to Stress Cracking

While HDPE geomembranes are durable under typical conditions, they can experience stress cracking when subjected to concentrated loads, sharp objects, or repeated mechanical stress. Proper padding and careful installation are crucial to mitigating these risks.

- Potential for Punctures

Sharp rocks or debris in the subgrade can puncture HDPE liners if not adequately prepared. The need for a meticulously smooth and debris-free surface increases preparation time and costs.

- Weight and Handling

HDPE liners, particularly in thicker grades, can be relatively heavy, presenting logistical challenges during transportation and on-site handling. This could lead to higher labor or machinery costs for deployment.

Understanding both the advantages and limitations of HDPE geomembranes is vital for selecting the appropriate design and material specifications for various applications. By addressing these challenges during project planning, the full potential of HDPE geomembranes can be achieved in numerous industries.

Key Differences Between HDPE and PVC Geomembrane

- Material Composition

- HDPE (High-Density Polyethylene) is a rigid, durable material known for its high chemical and UV resistance.

- PVC (Polyvinyl Chloride) is a more flexible material, offering better adaptability to uneven surfaces or complex shapes.

- Flexibility and Installation

- HDPE geomembranes are stiffer, requiring specialized equipment for installation, particularly on irregular terrains.

- PVC geomembranes are highly flexible, making them easier to handle and install in challenging site conditions.

- Durability

- HDPE membranes have superior resistance to environmental stressors, including UV radiation, chemicals, and extreme temperatures, providing a longer lifespan.

- PVC membranes, while less durable over time, perform effectively in applications where flexibility and ease of handling are prioritized.

- Application Suitability

- HDPE is ideal for long-term applications such as landfills, mining, or wastewater containment, where durability is critical.

- PVC is better suited for temporary uses or situations requiring adaptability, like decorative ponds or small-scale liners.

Understanding these distinctions can guide material selection to ensure optimal performance for specific project needs.

Material Composition: Polyvinyl Chloride vs High-Density Polyethylene

When comparing the material composition of Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE), I focus on their distinct properties. PVC is primarily derived from chlorine and ethylene, resulting in a more rigid and less flexible structure, often requiring plasticizers to enhance its adaptability. On the other hand, HDPE is made from petroleum and is known for its high strength-to-density ratio. This gives it superior durability and flexibility without the need for additional additives. Understanding these differences helps me choose the right material based on project requirements, whether I need rigidity or resilience.

Performance Factors: Chemical Resistance, UV Stability, and Durability

Chemical Resistance

Both PVC and HDPE exhibit strong resistance to various chemicals, making them suitable for industrial applications. However, HDPE generally outperforms PVC when exposed to a broader range of solvents and corrosive substances, such as acids and alkalis. HDPE’s non-polar structure gives it an advantage, as it does not easily react with chemical agents. For instance, HDPE pipelines are often utilized in environments with high acidity or alkalinity, where prolonged exposure to chemicals is common. PVC, while also chemically resistant, is highly effective in applications involving less aggressive substances, such as residential piping.

UV Stability

When exposed to prolonged sunlight, PVC can degrade over time unless stabilizers or additives, like titanium dioxide, are integrated into its formulation. HDPE, on the other hand, demonstrates better inherent UV resistance due to its higher molecular density, which enhances its stability under direct sunlight. Nevertheless, both materials can benefit from protective coatings or UV stabilizers to extend their lifespan in outdoor applications. HDPE is often preferred in environments with high UV exposure, such as agricultural and irrigation systems.

Durability

Durability is a defining feature for both PVC and HDPE, but their performance depends on specific conditions. PVC’s rigidity makes it ideal for high-pressure systems or applications requiring structural integrity. Conversely, HDPE’s flexibility allows it to handle external impacts and ground movement exceptionally well, reducing the risk of fractures. For instance, HDPE pipes demonstrate a higher tolerance for freeze-thaw cycles, which can be critical in colder climates. Laboratory tests indicate HDPE’s lifespan can exceed 50 years in appropriate conditions, making it a long-term solution for infrastructure projects. PVC, while slightly less durable in rough conditions, maintains its reliability in controlled environments over similar time spans.

Understanding these nuanced performance factors ensures the selection of the most suitable material for specific environmental and project demands.

Cost Considerations and Lifespan

HDPE and PVC materials show notable differences when comparing cost-effectiveness and lifespan, both of which are vital for project planning and budgeting. HDPE typically has a lower upfront cost per unit weight compared to PVC, making it a more economical choice for large-scale applications. However, when factoring in installation costs, HDPE might require specialized equipment for heat fusion or welding, slightly increasing initial expenses. PVC, on the other hand, is easier to work with during installation due to its relatively lightweight nature and use of simple solvent cement joints, often leading to reduced labor costs.

Over time, the long lifespan of both materials contributes to their overall value. HDPE pipes are particularly renowned for their resistance to cracking and fatigue, remaining effective for 50 to 100 years depending on environmental factors. Similarly, PVC pipes boast an average lifespan ranging from 50 to 70 years, particularly in low-stress applications. According to industry data, both materials offer strong lifecycle performance, but the specific cost-to-lifespan ratio often depends on the intended use, soil conditions, and required maintenance levels. By combining these considerations, decision-makers can identify the most cost-efficient option tailored to their project’s unique demands.

How to Choose Between HDPE and PVC Geomembrane Liners

When choosing between HDPE and PVC geomembrane liners, consider the following key factors:

- Durability Requirements: HDPE liners are highly resistant to chemicals, UV radiation, and harsh environments, making them ideal for long-term applications in challenging conditions. PVC liners are more flexible and better suited for projects with irregular surfaces or where higher adaptability is required.

- Project Budget: HDPE liners may have a higher upfront cost but offer a longer lifespan and minimal maintenance, which can lead to lower long-term costs. PVC liners are generally more affordable in the short term but might require replacement sooner.

- Installation Ease: PVC liners are lighter and easier to handle during installation, especially for smaller or more complex projects. HDPE liners, while durable, are heavier and can require more specialized equipment for proper placement.

- Environmental Considerations: If your project involves extreme temperatures or exposure to aggressive chemicals, HDPE is often the better choice. PVC can perform well in moderate conditions but may be less effective in highly demanding environments.

By aligning the characteristics of each material with the unique requirements of your project, you can make an informed decision that balances performance, cost, and longevity.

Evaluating the Specific Requirements of the Project

When evaluating project requirements, it is essential to combine an understanding of material properties with relevant, up-to-date data. Both HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride) offer distinct advantages depending on environmental conditions, pressure demands, and chemical exposure levels.

- Durability Under Pressure: Studies indicate that HDPE pipes can handle higher levels of pressure fluctuations compared to PVC, particularly in systems requiring flexibility and resistance to cracking. For instance, HDPE has a ductile failure point, allowing it to stretch under stress, whereas PVC is more likely to experience brittle failure in high-pressure scenarios.

- Temperature Resistance: HDPE maintains operational integrity in temperatures ranging between -40°F and 140°F, making it suitable for extreme weather conditions or environments with significant temperature variations. On the other hand, PVC is generally rated for temperatures between 32°F and 140°F, being less effective in freezing conditions.

- Longevity and Maintenance: The lifespan of a material is critical for assessing its suitability for long-term applications. Data suggests HDPE pipes can last up to 50–100 years in ideal conditions, thanks to their superior stress crack resistance. PVC can also achieve a similar lifespan in stable environments but may degrade faster under heavy UV exposure without proper coatings.

- Cost Efficiency and Installation: While the upfront cost of PVC is often lower, HDPE is recognized for its ease of installation, particularly in trenchless applications like horizontal directional drilling. These cost-saving installation methods may outweigh the initial price difference, especially for large-scale infrastructure projects.

- Environmental and Regulatory Trends: As sustainability becomes increasingly important, HDPE’s fully recyclable properties and reduced carbon footprint during production make it more aligned with eco-conscious projects. Advances in PVC formulations are closing the gap, but careful evaluation of the environmental impact remains key.

By analyzing these metrics and choosing a material that aligns with the specific operational demands and long-term goals of your project, you ensure optimal performance and cost management. Comparing these factors against modern industry benchmarks allows for a dynamic, well-rounded implementation strategy.

Assessing Environmental Factors and Containment Needs

When selecting materials and systems for industrial or commercial applications, environmental factors and containment needs are pivotal considerations. Environmental conditions such as temperature extremes, UV exposure, chemical interactions, and moisture levels directly affect the durability and performance of materials. For example, studies show that high UV exposure can degrade certain plastics over time, leading to cracking or loss of flexibility. Employing UV-stabilized materials or coatings can mitigate these risks, ensuring long-term resilience.

Containment needs present an equally critical aspect. Managing hazardous or sensitive substances requires materials with excellent chemical resistance and leak-proof properties. High-density polyethylene (HDPE) lining is often preferred for its superior chemical compatibility, withstanding a variety of acidic and alkaline substances. Similarly, double-containment piping systems have demonstrated significant reductions in spill incidents by offering an added layer of security.

Data from industry reports indicate that over 60% of material failures in containment scenarios are attributed to a mismatch between material properties and environmental conditions. To address this, performing a thorough compatibility analysis and adopting advanced technologies, such as real-time monitoring sensors in containment systems, ensures a proactive approach to mitigating risks. By integrating detailed environmental assessments with robust material and system selection, project outcomes can be both efficient and environmentally sustainable.

Consulting with Experts to Determine the Best Geomembrane

When selecting the optimal geomembrane for a specific project, consulting with industry experts provides critical insights and ensures informed decision-making. Experts assess various factors such as the project’s scope, environmental conditions, and regulatory requirements. For example, professionals often consider the chemical resistance of high-density polyethylene (HDPE) geomembranes, which are widely recognized for their durability and cost-effectiveness. According to recent market data, HDPE geomembranes dominate the industry, accounting for over 35% of the market share, particularly in applications like landfill liners and water reservoirs. These materials excel due to their strength and capacity to withstand adverse weather conditions.

For situations where flexibility and elongation are vital, linear low-density polyethylene (LLDPE) geomembranes or PVC-based alternatives might be more suitable. Research highlights their reliability in applications requiring adaptability to uneven surfaces or frequent ground movement. Additionally, experts evaluate multilayer co-extruded geomembranes, which combine various polymer properties into a single sheet, enhancing their resistance to UV radiation and chemical degradation.

By leveraging this expertise, stakeholders can optimize material choice, balancing cost, performance, and environmental sustainability. Partnering with professionals not only reduces the risk of material failure but also ensures compliance with evolving industry standards and regulations.

Similarities and Synergies: HDPE Geomembrane and PVC Geomembrane

Both HDPE (High-Density Polyethylene) and PVC (Polyvinyl Chloride) geomembranes serve as reliable options for waterproofing and containment in various industrial and environmental applications. They share several similarities, such as exceptional impermeability, high resistance to chemical exposure, and suitability for long-term use in harsh conditions. Both materials are also lightweight, making them easier to transport and install compared to more traditional alternatives. Furthermore, HDPE and PVC geomembranes are versatile, offering adaptability to diverse project requirements, including landfill liners, mining applications, and water storage systems. Their shared durability and cost-effectiveness make them popular choices across numerous industries.

Common Applications and Geomembrane Material Choices

Geomembranes play a critical role across multiple industries due to their capacity to provide an impermeable barrier in various containment systems. Below are some widely recognized applications and factors influencing material selection:

1. Landfill Liners and Caps

Geomembranes are essential components in landfills, serving as liners to prevent leachate from contaminating groundwater and caps to reduce the infiltration of rainwater. According to industry data, HDPE geomembranes are the most commonly used material for landfill applications as they offer excellent chemical resistance and tensile strength, ensuring long-term containment efficiency and compliance with environmental regulations.

2. Mining Industry

The mining sector utilizes geomembranes extensively for heap leach pads, tailings storage, and process water containment. PVC and HDPE materials are often preferred, with HDPE offering durability under high stress from heavy loads and acidic conditions. Studies show that geomembranes in mining significantly reduce environmental risks by mitigating chemical leakage and optimizing resource recovery processes.

3. Water Containment Systems

For reservoirs, canals, and wastewater treatment plants, geomembranes act as impermeable barriers, preventing water loss and contamination. LDPE and PVC geomembranes are frequently employed due to their flexibility and ease of installation over irregular surfaces. PVC is especially appreciated in these systems for its adaptability and high friction properties, which are crucial in channels with steep gradients.

4. Agricultural Applications

Agricultural efficiency can be improved with geomembrane-lined irrigation ponds and silage covers to manage water effectively and protect resources. Research emphasizes the effectiveness of geomembranes in reducing water seepage losses, with estimates indicating savings of 50% to 70% in arid regions where water resources are scarce.

5. Oil and Gas Industry

The containment of hazardous materials, secondary containment systems, and drilling fluid pits in the oil and gas industry rely heavily on high-quality geomembranes. HDPE is a dominant material in this sector, providing protection against petroleum spillages and chemical exposure while withstanding temperature extremes.

Shared Advantages in Leakage Prevention and Durability

Geomembranes, particularly those made from HDPE, offer unparalleled protection when it comes to leakage prevention and long-term durability. Reports indicate that HDPE geomembranes have a very low permeability rate, often reaching levels as minimal as 1×10^-13 cm/sec. This highly impermeable quality ensures that hazardous materials, chemicals, or liquids remain securely contained, minimizing environmental risks.

Furthermore, geomembranes are engineered to resist chemical degradation, UV exposure, and extreme fluctuations in temperature, making them suitable for diverse climates and challenging applications. Studies have shown that HDPE geomembranes can maintain functionality for over 20 years in outdoor exposed environments, while buried installations can extend their lifespan to up to 50 years or more. These properties not only safeguard the integrity of sensitive materials but also reduce maintenance costs and prolong operational efficiency across industries ranging from mining to wastewater treatment.

This combination of exceptional leakage prevention and durability highlights why geomembranes are a trusted solution in critical containment systems worldwide.

Integration in Geosynthetic Systems

Geomembranes serve as a fundamental component within geosynthetic systems, often working in tandem with geotextiles, geogrids, and drainage layers to create robust, multilayered solutions. Their versatility enables applications in landfill liners, mining tailings containment, and water reservoir construction. For instance, the combination of geomembranes with geotextiles enhances the overall tensile strength of the system while providing additional protection against punctures and abrasions.

Recent advancements in geosynthetic technologies have improved system performance significantly. Studies indicate that high-density polyethylene (HDPE) geomembranes exhibit excellent chemical and UV resistance, with reported service lifespans exceeding 70 years in controlled conditions. Additionally, composite liner systems—where geomembranes work alongside compacted clay layers or geosynthetic clay liners—are now achieving leakage rates as low as 10⁻¹¹ m/s, meeting stringent environmental compliance standards.

Furthermore, geomembranes’ role in water management has grown substantially. Modern irrigation reservoirs supported by geosynthetic liners are conserving up to 95% of stored water by minimizing seepage, a critical statistic for regions combating water scarcity. By integrating geomembranes with other geosynthetic materials tailored to specific site conditions, engineers are achieving optimized containment solutions that are both environmentally sustainable and cost-effective.

Reference Sources

- Evaluation of mechanical and thermal properties after chemical degradation of PVC and HDPE geomembranes – This paper examines the mechanical and thermal properties of PVC and HDPE geomembranes under chemical exposure.

- HDPE geomembranes: A liner material for reservoirs – This study compares different geomembrane types, including PVC and HDPE, for use in reservoir lining systems.

- Evaluation of liners for a uranium-mill tailings disposal site: a status report – This report evaluates liner materials, including PVC and HDPE, for their effectiveness and durability in specific applications.

Top PVC geomembran Suppliers in China

Frequently Asked Questions (FAQs)

Q: What is a geomembrane liner?

A: A geomembrane liner is a type of geosynthetic material used to control fluid movement in projects such as fish ponds, waste containment, and various civil engineering and environmental applications. It acts as a barrier to prevent leaks and is commonly made from thermoplastic polymers.

Q: What is the difference between HDPE geomembrane and PVC geomembrane liners?

A: The notable differences between HDPE geomembrane and PVC geomembrane liners include their material composition and performance characteristics. HDPE (High-Density Polyethylene) is known for its good resistance to temperature, chemicals, and UV radiation, while PVC (Polyvinyl Chloride) offers higher elongation at break, making it more flexible. The choice between them often depends on the specific requirements of the application.

Q: How do HDPE and PVC geomembrane liners compare in terms of chemical resistance?

A: HDPE geomembrane liners generally have better resistance to a wider range of chemicals compared to PVC geomembrane liners. This makes HDPE suitable for applications involving aggressive chemicals, whereas PVC may be limited depending on the specific substances involved.

Q: Are there similarities between HDPE and PVC geomembrane liners?

A: Yes, both HDPE and PVC geomembrane liners are used in applications requiring reliable fluid containment. They are both thermoplastic polymers and serve as effective barriers in various geosynthetics projects. However, their performance characteristics differ based on their individual material properties.

Q: What factors should be considered when choosing between HDPE and PVC geomembrane liners?

A: The choice between HDPE and PVC geomembrane liners depends on factors such as chemical exposure, temperature conditions, required flexibility, and the specific environmental conditions of the project. Consulting with a geomembrane manufacturer can provide guidance based on these considerations.

Q: What applications are HDPE geomembrane liners suitable for?

A: HDPE geomembrane liners are suitable for applications requiring high resistance to chemicals, UV radiation, and temperature variations. They are commonly used in waste containment, mining, and as HDPE pond liners for fish ponds.

Q: In what scenarios are PVC geomembrane liners preferred over HDPE?

A: PVC geomembrane liners are preferred in scenarios where flexibility and elongation at break are crucial, such as in applications where the liner must conform to complex shapes or where ground settling is expected. PVC ponds and certain civil engineering projects may benefit from this flexibility.

Q: How does the texture of HDPE geomembrane liners affect their performance?

A: Textured HDPE geomembrane liners provide improved frictional properties, which can enhance stability on slopes and in areas requiring increased traction. Smooth HDPE liners, on the other hand, are often used in applications where a low friction surface is desirable.

Q: What are the environmental benefits of using geomembrane liners?

A: Geomembrane liners, including both HDPE and PVC options, offer environmental benefits by preventing contamination of soil and groundwater. They are used in waste containment and other environmental protection applications, contributing to sustainable civil engineering and environmental practices.