When it comes to safeguarding our environment and managing vital water resources, geomembranes play a pivotal role behind the scenes. These advanced synthetic materials serve as the backbone of countless containment and protection systems, helping to prevent pollution, conserve resources, and ensure sustainability. From lining landfills to preventing hazardous waste leakage, to supporting efficient water storage and irrigation systems, geomembranes provide an unparalleled solution for some of the most pressing challenges faced by industries and communities today. This article dives into why geomembranes are essential, exploring their innovative applications, environmental benefits, and the critical role they play in advancing sustainable practices. Whether you’re an environmental engineer, a policymaker, or simply a curious reader, this comprehensive guide will shed light on how these remarkable materials are shaping a greener, more resilient future.

What is a geomembrane?

A geomembrane is a synthetic membrane used as a barrier to prevent the movement of liquids or gases within a specific area. Made from materials like polyethylene or PVC, geomembranes are highly durable and impermeable, making them essential for applications such as waste containment, water storage, and environmental protection. They are widely used in landfills, reservoirs, and other containment systems to ensure effective and long-lasting sealing solutions.

Types of geomembranes

- High-Density Polyethylene (HDPE) Geomembranes

HDPE geomembranes are widely used due to their high strength, chemical resistance, and durability. They are highly impermeable and suitable for applications requiring long-term stability, such as landfill liners, mining operations, and wastewater treatment ponds.

- Low-Density Polyethylene (LDPE) Geomembranes

LDPE geomembranes offer greater flexibility compared to HDPE variants, making them ideal for projects requiring enhanced adaptability to uneven surfaces. They are commonly used in smaller containment applications, such as canals and decorative pond liners.

- Linear Low-Density Polyethylene (LLDPE) Geomembranes

LLDPE geomembranes combine the strength of HDPE with the flexibility of LDPE. Known for their excellent elongation properties, they are suitable for applications requiring high resistance to stress cracking, such as reservoirs and aquaculture ponds.

- Polyvinyl Chloride (PVC) Geomembranes

PVC geomembranes are flexible and easy to install, often preferred for temporary projects or applications requiring intricate custom fitting. They are commonly used in agricultural ponds and small reservoirs but tend to have a shorter lifespan compared to polyethylene options.

- Ethylene Propylene Diene Monomer (EPDM) Geomembranes

EPDM geomembranes are highly durable, resistant to UV radiation, and retain flexibility even in extreme temperature conditions. These properties make them ideal for decorative ponds, irrigation canals, and other outdoor water containment systems.

- Geosynthetic Clay Liners (GCLs)

GCLs are composed of layers of geotextile fabrics encapsulating a layer of bentonite clay. While not a traditional geomembrane, they function as an impermeable liner by swelling upon exposure to water, effectively creating a barrier. They are used as an alternative in landfill liners and other containment systems.

Each type of geomembrane has specific advantages tailored to different project needs, making it essential to select the appropriate material based on environmental conditions, budget, and application requirements.

Materials used in geomembrane production

Geomembranes are commonly manufactured from a variety of polymers, each chosen for its specific properties and performance in different applications. Below are some of the primary materials used in geomembrane production:

- High-Density Polyethylene (HDPE):

HDPE is a widely used material due to its high chemical resistance, durability, and cost-efficiency. It is particularly effective in applications involving harsh chemicals or extreme environmental conditions. HDPE geomembranes typically have a density range of 0.94 to 0.97 g/cm³ and a tensile strength exceeding 18 MPa, allowing them to withstand significant stress.

- Low-Density Polyethylene (LDPE) and Linear Low-Density Polyethylene (LLDPE):

LDPE and LLDPE geomembranes are known for their flexibility and adaptability. LLDPE, in particular, offers improved elongation characteristics, making it suitable for areas requiring movement or ground settling. Common thicknesses range from 0.5 mm to 2.5 mm, catering to diverse project needs.

- Polyvinyl Chloride (PVC):

PVC geomembranes are highly flexible and easy to install, making them popular for temporary containment solutions or smaller-scale applications. However, PVC tends to have lower chemical resistance compared to HDPE. These membranes generally include plasticizers, which enhance flexibility but may impact long-term performance.

- Ethylene Propylene Diene Monomer (EPDM):

EPDM geomembranes are renowned for their elasticity and weather resistance. Suitable for ponds, reservoirs, and other water containment systems, EPDM can stretch up to 300% of its original size while maintaining integrity. This material is preferred for projects requiring long-term durability and exposure to UV radiation.

- Polypropylene (PP):

Polypropylene geomembranes offer excellent resistance to punctures and are increasingly used in applications such as landfill liners and wastewater treatment facilities. Their non-toxic nature is particularly beneficial in agricultural settings, such as irrigation canals and storage ponds.

- Geosynthetic Clay Liners (GCLs):

Although not polymer-based, GCLs consist of bentonite clay sandwiched between geotextiles or bonded to a geomembrane. When hydrated, the clay swells and forms a low-permeability layer, providing an effective barrier. GCLs are often used in combination with other geomembranes for enhanced protection.

Each of these materials is tailored to meet specific construction, environmental, and economic demands. Recent developments in polymer technology are continually enhancing the strength, flexibility, and chemical resistance of geomembranes, ensuring their reliability in a wide range of industries.

How geomembranes are used in various industries

Geomembranes play a vital role across numerous industries due to their durability, impermeability, and adaptability. In the mining industry, geomembranes are widely used for heap leach pads to contain and manage leachate during the extraction of precious metals like gold and copper. Studies show that the use of geomembrane liners can achieve containment efficiencies of over 99%, ensuring minimal environmental contamination.

Similarly, in the waste management sector, geomembranes are critical in landfill construction, lining systems, and capping. They provide effective barriers to prevent leachate seepage, protecting groundwater resources. Modern landfill designs with geomembrane liners can significantly reduce the risk of leakage, aligning with stringent environmental regulations.

The agriculture industry also benefits from geomembranes, particularly in irrigation reservoirs, ponds, and canal lining systems. By minimizing water seepage losses, geomembranes help improve water conservation efforts for sustainable farming practices. For instance, geomembranes are found to reduce water loss by up to 90% when compared to unlined canals.

In the energy sector, geomembranes are crucial in containment systems for coal ash ponds, secondary fuel containment, and hydraulic fracturing (fracking) operations. Their chemical resistance ensures safe handling and storage of potentially harmful materials. Additionally, renewable energy projects, such as floating solar farms, increasingly use geomembranes to stabilize the bases of water reservoirs.

These versatile applications showcase the critical role of geomembranes in optimizing resource efficiency, enhancing environmental protection, and supporting the infrastructure needs of various industries. Ongoing advancements in materials science continue to expand their potential, offering even more effective solutions for industrial and environmental challenges.

How does a geomembrane liner work?

A geomembrane liner works by acting as an impermeable barrier to prevent the movement of liquids or gases through its surface. It is typically made from synthetic materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC), which create a durable and flexible sheet. When installed properly, the liner blocks leakage and contamination by sealing the area it covers, whether in landfills, reservoirs, or containment ponds. Its effectiveness relies on precise installation, secure seams, and a clean, stable surface to ensure long-term performance.

The science behind impermeable membranes

Impermeable membranes operate on the principle of blocking liquid and gas transmission through their structure, which is achieved by their composition and design. These membranes are composed of highly dense polymers, such as HDPE, PVC, or ethylene propylene diene monomer (EPDM), which create a barrier by minimizing pore spaces to near zero. Recent advancements in material science have introduced multilayered designs and reinforced geomembranes that enhance durability and resistance to environmental stresses.

For instance, HDPE sheets have tensile strengths that can exceed 21 MPa (megapascals) and are capable of withstanding significant elongation before reaching their breaking point, making them ideal for industrial and environmental applications. Additionally, innovative enhancements such as textured surfaces improve anti-slip properties, crucial for slopes and containment systems. Membranes designed for chemical resistance now incorporate compounds and treatments to withstand exposure to acids, bases, and hydrocarbons for extended periods, with lifespans reaching decades under proper conditions.

Tests performed on impermeable liners in controlled environments showcase minimal permeability rates, often below 1×10⁻¹² cm/sec, ensuring exceptional containment capabilities. These qualities make impermeable membranes critical in protecting natural resources, such as groundwater, from the leaching of hazardous materials in landfills and industrial storage basins.

Role in preventing water loss and contaminant seepage

Impermeable liners play a vital role in preventing water loss and minimizing contaminant seepage across a variety of applications. By serving as highly effective barriers, these liners are designed to restrict water from escaping reservoirs, irrigation canals, and ponds, thus optimizing water conservation efforts. Studies indicate that modern geomembranes can reduce water loss by up to 95%, significantly aiding agricultural and industrial processes that rely on sustained water availability.

Additionally, these liners safeguard surrounding ecosystems by preventing hazardous substances from infiltrating soil and groundwater. For instance, high-density polyethylene (HDPE) liners, one of the most commonly used materials, exhibit exceptional chemical resistance, ensuring longevity and effective containment even when exposed to harsh substances. Data suggests that HDPE liners used in waste containment systems can achieve permeability rates as low as 1×10⁻¹⁴ cm/sec, underscoring their efficiency in preventing the migration of toxic leachate. These advanced materials not only contribute to environmental protection but also support regulatory compliance, making them indispensable for sustainable development across industries.

Applications in hazardous waste containment

HDPE liners have become the gold standard in hazardous waste containment due to their high resistance to chemicals, durability, and superior impermeability. These liners are specifically designed to handle the storage and disposal of various hazardous materials, including industrial byproducts and chemical wastes, without risk of contamination to surrounding environments.

One notable application is their use in landfill containment systems, where HDPE liners act as an essential barrier against the migration of leachate—liquid that can seep through the waste material and potentially contaminate soil and groundwater. Studies reveal that HDPE geomembranes possess tensile strengths exceeding 25 MPa, ensuring long-term performance under mechanical stress and environmental pressures like temperature variations and UV exposure. Furthermore, their service life is estimated to exceed 400 years under optimal conditions, which is critical for industries requiring long-lasting solutions.

Beyond landfills, HDPE liners are also employed in the construction of chemical storage lagoons, ensuring that no hazardous liquids leak into the soil. Their chemical resistance properties enable them to withstand exposure to aggressive substances such as hydrocarbons, solvents, and acidic solutions, which can compromise less durable materials. Additionally, since HDPE liners maintain permeability rates as low as 1×10⁻¹⁴ cm/sec, they surpass many other materials in terms of efficiency and reliability.

Integrating HDPE liners into hazardous waste containment systems not only enhances environmental safety but also ensures regulatory compliance. Their unparalleled combination of mechanical strength, chemical resistance, and longevity makes them an invaluable solution across industries ranging from manufacturing and mining to energy production.

Why is geomembrane important for landfill containment?

Geomembranes are crucial for landfill containment because they act as a reliable barrier that prevents leakage of hazardous substances into the surrounding soil and groundwater. Their impermeable nature ensures that harmful chemicals, toxins, and waste byproducts are contained, reducing environmental pollution and protecting public health. Additionally, geomembranes enhance the long-term stability of landfills by preventing contamination and minimizing the risk of ecological damage. They are a critical component in meeting environmental regulations and maintaining sustainable waste management practices.

How landfill liners prevent environmental contamination

Landfill liners are designed with multiple layers, working in harmony to create an effective system that prevents environmental contamination. Modern landfill liners typically combine two essential layers—geomembranes and compacted clay. Geomembranes, often fabricated from high-density polyethylene (HDPE), serve as a primary layer due to their impervious nature and ability to resist chemical degradation. Compacted clay layers, on the other hand, act as a secondary barrier, enhancing the liner’s protective qualities by reducing permeability and ensuring long-term durability.

A critical function of these liners is to control leachate, a hazardous liquid composed of rainwater mixed with waste decomposition byproducts. Advanced landfill designs incorporate leachate collection systems placed above the liner to efficiently gather and redirect this liquid to treatment facilities, preventing its infiltration into groundwater. For example, studies report that HDPE geomembranes can achieve permeability rates as low as 1×10^-13 cm/s, ensuring minimal leakage.

Additionally, liners mitigate the release of landfill gases, such as methane and carbon dioxide, which are byproducts of decomposing organic matter. By incorporating gas collection systems alongside liners, landfills can capture and safely process these emissions, reducing their contribution to greenhouse gas effects. According to industry standards, well-designed landfill liners and gas management systems can capture up to 85% of landfill gas, significantly lowering environmental risks.

Through innovation and stringent safety protocols, landfill liners continue to evolve, becoming increasingly reliable and eco-friendly. These systems are indispensable in protecting soil, water resources, and air quality from the adverse impacts of waste disposal, ensuring a safer and more sustainable environment for generations to come.

Durability and reliability of hdpe geomembranes

High-density polyethylene (HDPE) geomembranes are revered for their exceptional durability and reliability, making them a preferred choice in a wide range of containment applications. These geomembranes offer remarkable chemical resistance, effectively withstanding exposure to harsh substances such as acids, alkalis, and hydrocarbons, which ensures long-term performance in challenging environments like landfills and mining operations.

A critical feature of HDPE geomembranes is their excellent mechanical strength. HDPE materials typically have a tensile strength range of 25 to 35 MPa, providing resilience against punctures, tears, and environmental stress cracking. Their durability is further enhanced by UV resistance, allowing them to maintain structural integrity under prolonged sunlight exposure.

HDPE geomembranes are engineered to operate within a wide temperature range, often from as low as -40°F (-40°C) to as high as 180°F (82°C). This ensures consistent performance even in extreme weather conditions. Furthermore, the lifespan of these geomembranes can extend over 30 years with proper installation and maintenance, showcasing their reliability in long-term containment solutions.

Another noteworthy aspect is their low permeability, measured in the range of 1×10^-12 cm/sec, which prevents seepage and protects underlying soil and groundwater from contamination. This characteristic, combined with advanced manufacturing technologies, provides optimal environmental protection, making HDPE geomembranes indispensable for sustainable infrastructure and waste management practices.

Environmental and health benefits of using geomembranes

Geomembranes offer a host of environmental and health benefits, making them a vital component in modern waste management and containment solutions. Their exceptional ability to act as impermeable barriers helps mitigate contamination risks by preventing hazardous chemicals and toxins from seeping into groundwater and soil. This ensures cleaner water supplies and protects ecosystems from pollution. A report from the Environmental Protection Agency highlights that properly installed geomembrane liners can reduce leachate escape by up to 97%, thereby safeguarding surrounding habitats and communities.

Beyond environmental protection, geomembranes also contribute to public health by minimizing exposure to harmful substances. For example, in landfill applications, they help contain methane gas—an odorless yet dangerous greenhouse gas—thereby preventing harmful emissions from disrupting nearby populations. Additionally, these membranes reduce the risk of disease spreading through contaminated soil or water, particularly in areas where industrial or municipal waste is managed.

Innovative applications in agriculture also underline their sustainability. Geomembranes are increasingly used in irrigation reservoirs and fish ponds to optimize water usage and prevent water loss, bolstering water conservation while maintaining the safety of both crops and aquaculture. These features showcase how geomembranes serve as essential tools in environmental stewardship and in fostering healthier living conditions for communities worldwide.

What are the benefits of geomembrane in water management?

Geomembranes provide significant benefits in water management by ensuring effective containment and minimizing water loss. Their impermeable properties prevent seepage in reservoirs, canals, and ponds, promoting water conservation and reducing waste. Geomembranes are durable and resistant to environmental factors, making them ideal for long-term use even in demanding conditions. Furthermore, they help maintain water quality by acting as a protective barrier against soil contamination and pollutants. These attributes make geomembranes an efficient and reliable solution for sustainable water management.

Reducing water loss due to seepage

I would recommend using high-quality geomembranes as an effective solution to reduce water loss due to seepage. These liners provide a robust and impermeable barrier, preventing water from leaking into the surrounding soil. By installing geomembranes in reservoirs, canals, or ponds, you can conserve significant amounts of water, ensure efficient usage, and enhance overall sustainability.

Enhancing water conservation efforts

Efforts to enhance water conservation have become increasingly vital as global water demands rise and climate change exacerbates water scarcity. A combination of advanced technologies and community-based initiatives is proving essential for addressing this challenge.

One compelling strategy involves the adoption of precision irrigation systems, such as drip and sprinkler irrigation, which reduce water usage by up to 50% compared to traditional flood irrigation methods. These systems ensure that water is delivered directly to the plants’ root zones in controlled amounts, minimizing evaporation and runoff. Another innovative approach is the integration of smart water management technologies, including Internet of Things (IoT)-enabled sensors and real-time monitoring systems. These tools help to accurately track water levels, detect pipeline leaks, and optimize usage patterns in agricultural and urban settings.

Rainwater harvesting is another impactful measure that has gained global traction. For instance, studies reveal that harvesting and storing rainwater can fulfill up to 40% of a household’s water needs in areas with proper infrastructure. On a larger scale, desalination technology is advancing rapidly, offering new ways to convert seawater into drinkable water. Today’s reverse osmosis systems have achieved energy efficiencies of up to 3.5 kilowatt-hours per cubic meter, significantly improving their feasibility for coastal regions facing freshwater shortages.

Education and community engagement also play a critical role. Programs designed to raise awareness about water-saving practices, such as fixing household leaks—which can waste 10,000 gallons of water annually in an average household—can lead to significant long-term savings. By combining these initiatives with robust policy frameworks and investment in water-efficient infrastructure, communities worldwide can ensure sustainable water management and preserve this vital resource for future generations.

Applications in reservoir and pond liner systems

Reservoir and pond liner systems play a critical role in efficient water storage and management across agricultural, industrial, and municipal sectors. These liners act as barriers, preventing water seepage and minimizing losses through the ground, which is essential in arid regions or areas with limited water availability. High-density polyethylene (HDPE) liners, for example, are favored for their durability, UV resistance, and low permeability, making them ideal for long-term use in reservoirs and ponds.

Modern advancements in liner technology have significantly improved their effectiveness. Studies indicate that properly installed liners can reduce water loss by up to 90%, greatly enhancing water retention capabilities. Additionally, the use of reinforced geomembranes ensures structural stability, even under extreme weather conditions or heavy loads, while maintaining eco-friendly practices by reducing the need for chemical water treatments.

These systems cater to diverse applications, including irrigation reservoirs for sustainable agriculture, aquaculture ponds for fish farming, and stormwater retention ponds to manage urban runoff and prevent flooding. By incorporating these innovative liner technologies, communities and industries can maintain vital water supplies, mitigate environmental impacts, and adapt to growing demands for water conservation and sustainability.

How is geomembrane installation conducted?

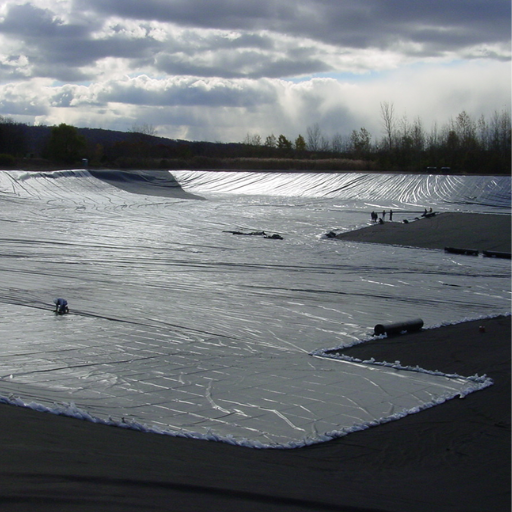

Geomembrane installation is conducted in a series of precise steps to ensure durability and effectiveness. First, the site is prepared by clearing debris and smoothing the surface to create a stable foundation. Next, the geomembrane sheets are carefully unrolled and positioned. Seams between sheets are then welded using specialized equipment to create a secure and watertight seal. The installation is completed with inspections to verify the integrity of the seams and the overall placement of the liner. Proper maintenance and quality control throughout the process are essential to ensure long-term performance.

Steps involved in geomembrane installation

- Site Preparation

Proper site preparation is critical for the success of geomembrane installation. The area is cleared of debris, vegetation, and sharp objects to create a smooth surface. Grading and compacting the soil ensure a stable foundation, with slope designs adjusted to meet project requirements.

- Unrolling the Geomembrane

Geomembrane sheets are delivered in large rolls and are carefully unrolled and positioned at the installation site. This step demands precision to align the sheets according to the design layout. Tools such as spreader bars may be used for efficient handling, especially when managing large rolls.

- Positioning the Sheets

After unrolling, the geomembrane sheets are spread out to cover the target area. Care is taken to minimize wrinkles and ensure proper overlap between adjacent sheets (typically 4 to 6 inches) to allow for secure seam welding.

- Seam Welding

Specialized equipment, such as hot wedge welders or extrusion welders, is used to join the overlapping sections of the geomembrane. Seam strength is vital in maintaining waterproofing integrity. Double-seam welds with an air channel in between are commonly applied for added security, enabling non-destructive testing.

- Inspection and Quality Assurance

Every seam undergoes rigorous inspection to detect potential defects or leaks. Non-destructive tests, such as air pressure tests or vacuum box tests, are conducted to confirm the quality of the welds. Visual inspections also verify the alignment and placement of the geomembrane sheets.

- Anchoring the Edges

The edges of the geomembrane are securely anchored, typically by burying them in anchor trenches around the perimeter. This prevents displacement due to wind, water, or other external forces, enhancing stability.

- Cover Material Application (if applicable)

For some projects, protective layers such as geotextiles or soil are placed above the geomembrane to shield it from ultraviolet radiation, punctures, or mechanical damage. The thickness and composition of the cover material depend on the specific application.

- Final Inspection and Documentation

A comprehensive inspection is carried out to ensure adherence to design requirements. All findings, including seam test results and visual inspections, are documented to verify compliance with project specifications. This step serves as the final verification before commissioning.

By following these detailed steps in sequence, geomembrane installation ensures durability, reliability, and long-term functionality for varied containment applications.

Ensuring ease of installation with modern techniques

Modern techniques have significantly enhanced the ease and precision of geomembrane installation. One notable advancement involves the use of automated welding equipment for seam creation. These machines not only improve efficiency but also ensure consistent, high-quality welds with reduced chances of human error. Studies highlight that automated welding can achieve success rates exceeding 95% in tests for seam strength and durability, reflecting its reliability in large-scale projects.

Another impactful innovation is the implementation of GPS-integrated surveying systems. These systems allow for precise geomembrane placement, avoiding misalignments and minimizing material waste. Data shows that projects incorporating GPS technology have seen up to 20% reductions in installation time, making it a cost-effective solution for demanding applications.

Additionally, lightweight and more flexible geomembrane materials have been developed, making handling and positioning far easier. These materials maintain high tensile strength and resistance to environmental factors, ensuring durability without compromising on ease of use.

By combining these advanced methods, modern geomembrane installation achieves an optimized balance between efficiency, accuracy, and the long-term integrity of the containment system.

Common challenges and solutions in geomembrane installation

The process of geomembrane installation, while crucial for numerous industries, is not without its challenges. Addressing these obstacles effectively requires careful planning, the incorporation of advanced technology, and skilled execution. Below are some of the key challenges faced during installation and the solutions to overcome them:

1. Ensuring Proper Subgrade Preparation

One of the leading challenges in geomembrane installation is preparing an appropriate subgrade surface. Uneven surfaces, sharp objects, or debris can damage the geomembrane, compromising its integrity.

Solution: Conduct comprehensive site surveys and employ professional grading equipment to achieve a smooth, rock-free surface. Using a protective geotextile underlayer beneath the geomembrane can further safeguard it from potential damage caused by residual irregularities.

2. Achieving Seam Integrity in Diverse Weather Conditions

Seam welding is critical in ensuring a leak-proof installation. Extreme weather conditions, including high winds, large temperature fluctuations, or rain, pose difficulties during this process, leading to irregular or weak seams.

Solution: Implement the use of advanced hot wedge or extrusion welding equipment that can adapt to varying conditions. Pre-scheduling installations to avoid harsh weather and utilizing temporary shelters on-site can minimize disruptions caused by environmental factors.

3. Quality Control During Installation

Lack of stringent quality checks during installation can lead to undetected defects, which may only surface over time, resulting in system failures and costly repairs.

Solution: Employ non-destructive testing (NDT) methods, such as vacuum box testing or air pressure testing, to assess the weld quality in real-time. Automation technologies equipped with sensors can further monitor installation processes for accuracy and efficiency.

4. Handling Material Expansion or Contraction

Geomembranes are susceptible to expansion and contraction due to temperature changes, leading to wrinkles or tension tears if not properly accounted for during installation.

Solution: Design the installation to accommodate thermal movement by leaving adequate slack during placement. Follow manufacturer guidelines for temperature ranges during installation and use anchorage systems to secure the material while allowing natural movements.

5. Ensuring Long-Term Performance in Harsh Environments

When deployed in environments with chemical exposure, UV radiation, or groundwater fluctuations, geomembranes can degrade over time if not properly chosen or installed.

Solution: Select geomembranes specifically engineered to resist project-specific environmental conditions, such as HDPE for chemical resistance or LLDPE for flexibility. Use UV-resistant coatings or coverings for additional protection against prolonged sun exposure.

6. Streamlining Large-Scale Installations

Industrial projects often require large-scale geomembrane deployments, presenting logistical challenges, such as managing material transportation, storage, and labor coordination.

Solution: Utilize precise project management tools to streamline resource allocation and scheduling. Modular preparations and pre-assembled material sections can save time and reduce complexity on-site. Drones and GPS-guided equipment further aid in efficient material placement over extensive areas.

By implementing these best practices and leveraging technological advancements, the challenges associated with geomembrane installation can be effectively mitigated, ensuring durability, efficiency, and compliance with industry standards.

Reference Sources

- Viscoelastic Contact Characteristics of Soil-Geomembrane – This source explores the interaction between soil and geomembranes, emphasizing the importance of understanding interface strength properties.

- The Role of Geomembrane Surface Roughness on Shear Behavior – A study on how surface roughness impacts the shear behavior of geomembrane/geotextile interfaces.

- Armored Geomembrane Cover Engineering – PMC – Highlights the role of geomembranes in modern engineered barriers to prevent stormwater and runoff infiltration.

Top Geomembrane Suppliers in China

Frequently Asked Questions (FAQs)

Q: What are geomembranes and why are they important in environmental protection?

A: Geomembranes are synthetic barriers used to control fluid movement and are essential for environmental protection because they prevent contaminants from seeping into the ground. They are often used to line landfills, storage facilities, and in waste management to ensure harmful substances do not pollute the environment.

Q: How do geomembranes contribute to effective water management?

A: Geomembranes are utilized in water management projects as they serve as impermeable barriers that prevent water leakage. They are used to line reservoirs, canals, and ponds, ensuring the safe storage and transport of clean water and preventing waste water from contaminating surrounding areas.

Q: What types of geomembranes are most commonly used?

A: There are several types of geomembranes, including HDPE (High-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), and PVC (Polyvinyl Chloride). HDPE geomembrane is particularly popular due to its durability, chemical resistance, and ability to withstand harsh environmental conditions.

Q: Why are geomembranes used to line landfills?

A: Geomembranes are used to line landfills to create a barrier that prevents leachate, a hazardous liquid formed from waste decomposition, from seeping into the soil and contaminating groundwater. This containment is crucial for protecting environmental health and maintaining clean water sources.

Q: How are geomembrane seams used in construction?

A: Geomembrane seams are used to join sheets of geomembrane material together, ensuring a continuous and impermeable barrier. Proper seam construction is critical to the effectiveness of geomembranes in preventing leaks and maintaining their integrity over time.

Q: In what other applications are geomembranes used?

A: Beyond landfills and water management, geomembranes are used in environmental projects like mining operations, agricultural ponds, and aquaculture. They provide reliable barriers for fluid containment, helping to protect ecosystems and manage resources sustainably.

Q: How does the use of geomembranes impact waste management?

A: In waste management, geomembranes are essential for containing and isolating waste materials, reducing the risk of environmental contamination. Their use helps in the safe disposal of waste and the protection of natural resources, contributing to more sustainable waste management practices.

Q: What are the benefits of using HDPE geomembrane in construction projects?

A: HDPE geomembrane is favored in construction for its high resistance to chemicals, UV radiation, and environmental stress. It is durable, cost-effective, and provides long-term performance, making it ideal for projects requiring robust and reliable fluid containment solutions.

Q: Can geomembranes be easily installed and maintained?

A: Yes, geomembranes can be easily installed and maintained. They are available in large sheets, which can be quickly laid out and welded together to form a continuous barrier. Routine inspections and maintenance ensure their longevity and effectiveness in various applications.