In the process of stabilizing driveways or landscapes, the proper selection of materials can be a determinant factor in the endurance and longevity of the project. Woven geotextile fabric is one of the materials that have recently created a huge stir in the planting and construction of the industries. This is a material that is to be the long-term solution in terms of controlling soil instability, erosion prevention, and hydraulic reinforcement, and therefore its durability and adaptability are the main factors of its wide acceptance. Whether you are a professional contractor, a gardener, or a homeowner doing it yourself, being aware of the benefits and applications of woven geotextile fabric can turn the scales in favor of getting excellent results.

Introduction to Woven Geotextile Fabric

What is Woven Geotextile Fabric?

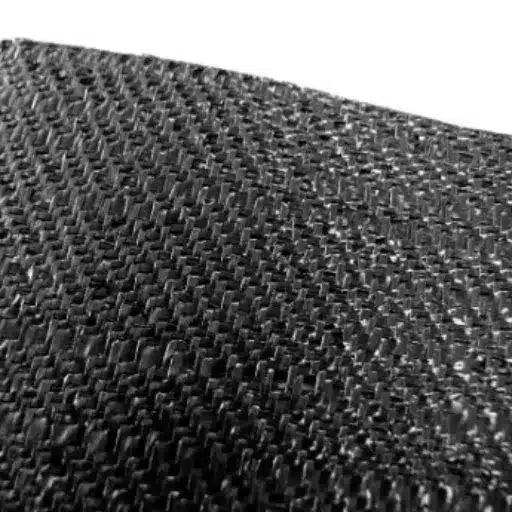

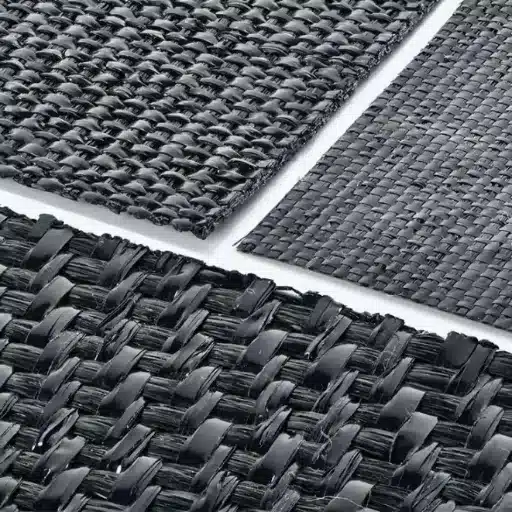

Woven geotextile fabric is an incredibly durable and versatile material that is made by interlacing individual polypropylene or polyester fibers into a strong, mesh-like structure. The main properties of this fabric are very high tensile strength, very low permeability, and consequently, it has been accepted in civil engineering, landscaping, and construction projects not only simply but also importantly as soil support, load distribution improvement and drainage control.

The fabric is most useful in those application areas where a long reinforcement is needed, such as roads, driveways, retaining walls, and erosion control systems. To give an example, woven geotextiles can support loads from 200 to more than 400 pounds per square inch (psi), which means they are perfect for heavy projects.

Besides, woven geotextile fabric is highly resistant to degrading by microorganisms and chemicals and thereby continues to be effective in a wide range of environmental conditions. When comparing woven with non-woven geotextiles the former gives an equal tensile strength but they are also more effective in the soil erosion control and at the same time the soil layers below are preserved.

The Need for Ground Support in Driveways and Landscapes

When it comes to driveway and landscaping support ground is very crucial for the improvement of both the utility and the lifetime of the surfaces. Supports not only allow the surfaces to resist, but also endure and weather all types of natural pressure such as rains, heavy traffic, and erosion and at the same time maintain their strength.

In the case of driveways, the ground support practiced in a methodical way is the ultimate solution for prevention of cracking, rutting, and sinking which are but a few problems that arise from the presence of poorly drained soils or from soil conditions that have been watered. Nowadays the use of geotextile fabrics as a fixing layer is credited with excellent load pressure distribution and thus the displacement of soil is significantly reduced. Currently, industry figures indicate that the use of geotextiles has the potential of increasing driveway load distribution by as much as 30% which means that maintenance costs would be significantly lower every project lifetime endured.

Similarly, stabilization in landscaping is of great necessity to enhance soil retention and thus filter crop planting. Soil anchors made of geogrids and geotextiles are not only stable but also restrict water runoff alongside their function of beautifying the landscape. Research has shown that if such measures are integrated through design in landscapes, it can lead to a 50% reduction in soil erosion, hence the landscape would be both sustainable and effective in the long run.

Benefits of Woven Geotextile Fabric

Heavy Duty Strength and Durability

The fact that woven geotextile fabric is a well-established and widely used material is totally contrary to its remarkable strength and durability and hence, it is a favored option for a variety of demanding applications. The production of these textiles entails the application of synthetic materials like polypropylene and polyester, which are so resilient and rough that even heavy loads cannot easily break or rip them apart. Their robust structure assures an extended duration of use, even in the most adverse circumstances.

Woven geotextile fabrics are applicable for both construction and landscaping providing a foundation capable of bearing weight greater than 200 pounds per square inch (PSI) making it a reliable choice for the stabilization of roads, walls, and drainage systems. As per the industry standards, the finest woven geotextiles can achieve an ultimate tensile strength of as much as 400 PSI, which is determined by the type of fiber and the weave density. Besides, they have very little elongation which helps to minimize the risk of any structural deformation taking place.

Soil Stabilization and Retention

Woven geotextiles are irreplaceable in the process of soil stabilization and retention and their major field of application is the areas where soil erosion or structural instability is a serious problem. The fabrics serve as a separation barrier as they allow the different soil layers to be separated without the danger of shifting or mixing. In other words, the soil above and below the geotextiles is becoming stronger and the loads are getting distributed evenly, so the infrastructure is getting easier and safer, e.g. roads, retaining walls, slopes, etc.

It is believed that soil erosion is causing a yearly loss of about 25 billion tons of fertile soil on a global scale which brings about a reduction in the output of the agricultural sector and deterioration of the ecosystem. When woven geotextiles have been incorporated into the erosion control systems, they have been found to reduce soil loss by over 90% in some cases, which is a significant move toward eco-friendliness. On top of that, modern geotextiles are produced in such a way that they not only withstand a variety of weather conditions but also come with the plus of being UV resistant and enduring in both wet and dry climates.

Filtration and Drainage Properties

Woven geotextiles are the ultimate solution for filtration and drainage function since their function is to retain even the smallest soil particles while the water goes through. This property makes them very powerful in the battle against soil erosion in high-water-flow areas like drainage ditches, retaining walls, and road subgrades. Research has shown that woven geotextiles still have permeability rates of 1.3 x 10^-4 m/s which is a very small figure in the context of efficient water draining without the loss of soil to the process.

Woven geotextiles are then used to perform as a barrier against heavy rain or in wetland areas with the function to preserve groundwater recharge while at the same time waterlogging is being reduced. Their high tensile strength and the right pore size distribution guarantee that they are not only very durable but also trustworthy under very large hydraulic stress. The application of these geotextiles in infrastructure projects will provide engineers with improved stability, more efficient water management, and ultimately, a longer life for the structures.

Applications of Woven Geotextile Fabric

Driveway Fabric for Stabilization

The woven geotextile fabric is the most significant factor in the stabilization of driveways due to its ability to prevent soil mixing and to keep the structure intact even under extremely heavy loads. The woven geotextiles are acting as a separator thus the quality of the gravel or aggregate base is maintained as it does not mix with the subsoil. With this, the outcome is a stronger, longer-lasting driveway that is able to resist heavy traffic and harsh weather conditions.

The latest studies indicate that applying woven geotextiles in the driveway can reduce the aggregate loss by up to 40% in comparison to the traditional methods that do not use fabrics. Besides, the high tensile strength of the woven geotextiles helps in better distribution of the load and thereby less rutting and deformation over time. Additionally, these fabrics are quite beneficial in soft soil situations as they create a soil with an improved load-bearing capacity and hence reduce the maintenance costs associated with it.

Landscape Fabric as a Weed Barrier

Landscape fabric is a functional and ideal tool for suppressing weed growth in gardens and landscaping. The fabric that allows water and nutrients to pass through but does not allow sunlight to reach the soil is the one that works as a weed control measure. According to recent research, the uptake of landscape fabric as a weed control method can diminish the weed population by up to 90%, thereby declaring it a very efficient method for long-term control of weeds.

Landscape fabric made from materials such as polypropylene and polyester is usually quite tough and resistant to tears, thus it can last for several growing seasons. It loses nothing when it comes to being a weed barrier if mulch or gravel is used since these additional layers provide the needed weight and prevent the fabric from being exposed to light. Proper ground preparation is required, that is, clearing the area of existing weeds and cutting the fabric to fit tightly around the plants while securely anchoring it to prevent shifting, to humans the best result.

Case Studies in Woven Geotextile Fabric Usage

Successful Driveway Installations Using Woven Geotextile Fabric

It is undoubtedly woven geotextile fabric that has established itself as a primary component in the driveway installation process and has significantly upsurged the overall stability, longevity, and cost-effectiveness of driveways. The fabric can separate soil layers that are quite essential in mixtures of materials, and hence, drainage, thus it is a wonderful barrier for such application. The even distribution of loads helps in ruts and other surface deformities.

The existing case studies show that there will be a 30% saving in the upkeep requirement for driveways made of woven geotextile fabric. One such instance from Colorado reported that the areas of the driveway that were exposed to heavy rains got better in durability than before. The use of woven geotextiles as a base layer under gravel made the driveway impervious to erosion and it sustained its structural integrity for 8 plus years through the very modest maintenance.

Landscape Projects Utilizing Geotextiles

Landscape projects’ dependency on geotextiles continues to grow and they are regarded as a crucial ingredient because of their versatility, durability, and possibility of heightening the project results. The main roles of these materials are to prevent erosion, strengthen the soil, and filter water, which is an ideal trio for both residential and commercial landscaping. To give an example in the case of retaining wall systems where geotextiles are utilized, they not just permit the water to seep through but also help to keep the soil in place which provides the system with both stability and longevity.

Another place where geotextiles are deemed very important is in garden trails and elegant patios made with decorative stones. The reason being these substrates act as a separating layer that stops the mixing of stones or gravel with soil thereby enhancing the longevity of these features and making them less maintenance. According to a 2023 landscape trends report, the total maintenance cost over the long run could be reduced as much as 25% if the pathways are constructed with geotextiles since the latter not only prevent weed growth but also last longer.

Environmental Impact of Woven Geotextile Fabric

Benefits to Soil Health and Ecosystem

Woven geotextile fabrics play a crucial role in maintaining soil health and supporting the ecosystem by providing stabilization, controlling erosion, and utilizing land management practices that are eco-friendly. Such fabrics somewhat act like shields which are responsible for the reduction of soil detachment due to water or wind and thus, protecting the uppermost layer of soil. This is important because, according to the Food and Agriculture Organization (FAO), about 24 billion tons of arable land are lost to erosion each year.

Furthermore, one of the major implications of the use of geotextiles is the enhancement of soil structure through the formation of the right conditions for drainage and at the same time, water logging is prevented thus allowing healthier root systems of the plants to develop. Furthermore, woven geotextiles are able to conserve the ecosystem as they curtail the amount of sediment that enters the water bodies thereby keeping the quality of water and the aquatic habitat development alive. For example, studies have shown that the implementation of geotextile in agricultural and building practices can lead to a reduction of up to 50% in sediment runoff.

Long-Term Sustainability of 50-Year Fabric

The durability and sustainability characteristics of 50-year fabrics, which are commonly used for geotextile applications, are without a doubt the main reasons that make them unavoidable in being part of the environment-friendly strategies and the modern construction projects that are not detrimental to nature. Such companies can make materials that can withstand years even in the harshest conditions like UV rays, water, and abrasion, and one is the geotextile that has very little breakdown.

From the perspective of the environment, the toughness of these fabrics results in a substantial reduction in the frequency of fabric changes, which subsequently causes a significant reduction in both the volume of waste materials produced and the carbon footprint associated with the production and disposal. In addition, the geotextile fabrics have been linked to better soil health and less erosion since they form barriers that not only support the ground but also allow the growth of vegetation over time. For instance, a project involving these fabrics which is not harmful to the environment has recorded a 60% decrease in the erosion rate in the high rainfall areas.

Reference Sources

-

An Overview of Geotextiles: Industrial Application in Technical Textiles

- Published by: Semantic Scholar

- Key Findings: This paper provides an overview of geotextiles, emphasizing the widespread use of woven geotextiles in industrial applications. It highlights their composition, such as monofilament polyester fabrics and polypropylene-based woven straps, and their preference in 70% of cases.

- Methodology: Review of industrial applications and material properties of woven geotextiles.

- Read more

-

Filter Rules for Soil and Geosynthetics

- Published by: Semantic Scholar

- Key Findings: This study discusses the design criteria for geosynthetic filters, including woven geotextiles, in soil filtration applications. It highlights the stricter design requirements for woven geotextiles compared to non-woven alternatives.

- Methodology: Analysis of geosynthetic filter applications and design rules.

- Read more

-

A Reinforcing Method for Steep Clay Slopes Using a Non-Woven Geotextile

- Published by: ScienceDirect

- Key Findings: While focused on non-woven geotextiles, this paper provides comparative insights into the mechanical properties of woven and non-woven geotextiles, particularly in reinforcement applications for steep clay slopes.

- Methodology: Experimental evaluation of geotextile reinforcement methods.

- Read more

Frequently Asked Questions (FAQs)

What is woven geotextile fabric, and what does it do as a road fabric exactly?

Woven geotextile fabric is a synthetic fabric that is made as a woven sheet of polypropylene or some other kind of polymer that goes through the slit film weaving process of strong fabrics to yield a high strength fabric used in road stabilization and separation. The road fabric yields a lot of advantages like: it will support the road, it will prevent mixing of subgrade soils with aggregate, it will act as a geotextile filter thus aiding drainage, and it will consequently lessen rutting and pothole formation on all paved and unpaved roads.

How does the woven fabric contribute to the subgrade stabilization and ground stabilization process?

The woven fabric provides the distribution of load stability and the improvement of the weak subgrade layers through the reinforcement and separation. The fabric with its high grab tensile strength and tear resistance minimizes differential settlement and rutting therefore making it suitable for various applications such as road, railway ballast, paving lots, and other ground stabilization. The installation crew typically places the woven fabric on the subgrade directly as an underlayment to segregate soil from aggregate and to stabilize the pavement structure.

Are any of the woven geotextiles rated for a 50-year lifespan, and what determines the longevity of such fabrics?

Woven geotextiles made from polypropylene types have a 50-year lifespan owing to their polymer stabilization, UV resistance, and rapid aging tests. The longevity of a product is based on laboratory testing of UV, oxidation, and creep along with the performance of the product in the field, plus the guidelines of ASTM and AASHTO as well as the outcome of NTEP tests are what form the basis for life expectancy claims. The right installation procedure which comprises covering the fabric, the prevention of prolonged UV exposure, and protecting the fabric from rotting or chemicals will also contribute to extending its life in roadway, parking lot, and rip rap applications.

Can woven geotextile type stabilize and support paver installations?

Yes, it can. Woven fabric underlayment for the paver system offers stabilization together with separation of the base materials and subgrade, enhancement of load transfer, reduction of sand migration that leads to uneven pavers, etc. The strong woven polypropylene fabrics are commonly placed under the pavers in driveways, walkways, and parking lots. They are puncture resistant, maintain the dimensional stability of the traffic area, and when perfectly compacted and restrained at the edges, they not only help prevent potholes and thus also edge breakage.