When it comes to construction, landscaping, and other environmental projects, the choice of materials could cement or undermine the long-term durability and functionality of the project. Geotextiles are an integral factor in such applications and many solutions are offered, including soil stabilization, erosion control, dewatering, etc. But with two main types, woven and non-woven geotextiles, how do you decide what would work best for your project? The blog compares and contrasts these two fabrics; discussing their specific properties, applications, and benefits. Whether you are a contractor, engineer, or a DIY guy, there prepare to gather the information of your choice. Stay with us as we go through the basic contrasts and arrive at the best fit for your needs.

Introduction to Geotextile Fabrics

Gives geotextile fabrics are designed to enhance construction work’s performance and durability by acting as reinforcement, filtration, drainage, and separation. Coming from either synthetic or natural fibers, they effectively distribute loads, erode lands, or restrain water flow depending on their application. Hence, their enormous range of applications interweaves civil engineering, agriculture, and environment restoration. With infrastructure designs incorporating geotextile fabrics, therefore, one has durability coupled with low maintenance, as well as greater sustainability of a project, truly attesting to the role they must play in modern-day construction.

Definition of Geotextile Fabrics

If anything, geotextile fabrics are textile sheets permeable through which civil engineering, environmental, and construction projects pass. Usually acting from polypropylenes or polyesters, such geotextile materials found various uses reinforcing, filtering, separating, and draining. They are the major input making sure such infrastructure as roads, retaining walls, drainage systems, or landfills are stable in performing well in the longevity of their function.

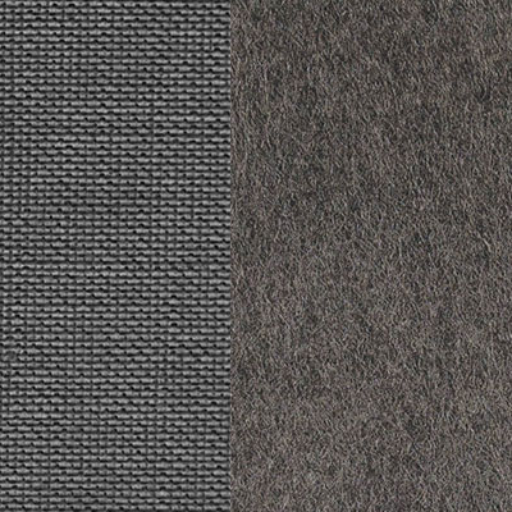

Generally, geotextiles are classified into two major types: the woven and non-woven. Woven fabrics are formed by systematically interlacing filaments, and high tensile strength and durability are some of their characteristics, thus best employed in applications that require high bearing loads such as road bases or railway reinforcement. Non-woven geotextiles are created by bonding fibers either thermally, chemically, or mechanically by needle punching, and appreciated for their filtration and drainage properties; they find wide application in situations where efficient water flow is required to prevent soil erosion, for example, in stormwater management systems or drainage layers under roads and pavements.

Furthermore, market studies also showcase that demand for geotextiles is increasing globally, with the market size expected to grow considerably in the coming years. For example, a report from Fortune Business Insight estimates the global geotextile market to increase from USD 8.10 billion in 2021 to USD 13.17 billion by 2029, growing at a CAGR of 6.2%. As a result of the implemented emphasis on sustainable infrastructure development and the increased demand for materials that could improve the longevity of construction projects, the market is expanding.

With innovations in geotextile technologies, their applications extend further, with advanced biodegradable geotextiles intended for temporary use or in environmentally sensitive projects. The continued development signifies the indispensability of geotextile fabrics toward the evolution of modern construction and environmental management practices.

Importance of Geotextile Fabric in Construction and Landscaping

Geotextiles find indispensable application in building and landscaping works as they contribute to structural stability, encourage conservation, and minimize maintenance costs. The permeable fabric is used in separation, filtration, reinforcement, drainage, and erosion control activities. In road construction, in addition, they prevent soils of different layers from mixing up, thus increasing durability while shortening repair periods. According to market reports, the geotextile industry is projected to record a Compound Annual Growth Rate (CAGR) of above 6% between 2023 and 2030, suggesting that they are increasingly adopted in infrastructural projects across the globe.

Landscaping applications only confirm the versatility of geotextile fabrics. For instance, they are used widely as ground stabilization measures to reduce soil erosion and give drainage to gardens, retaining walls, and slopes. Biodegradable geotextiles have seen growing applications in environmentally sensitive areas, offering temporary stabilizing benefits with low environmental costs. For example, hydrophilic geotextiles should allow ample water movement with low attenuation that facilitates sustainable water management for landscaping projects. Hence, by providing functional superiority as well as environmental benefits, geotextile fabrics are pivotal in shaping resilient infrastructure and green spaces.

Types of Geotextiles: Woven and Non-Woven

Generally, geotextiles are divided into two categories: woven and non-woven, and each is employed for different purposes depending on their structural properties and manufacturing processes. It is imperative to acknowledge the characters of these geotextiles for the best use in engineering works, construction, and environmental projects.

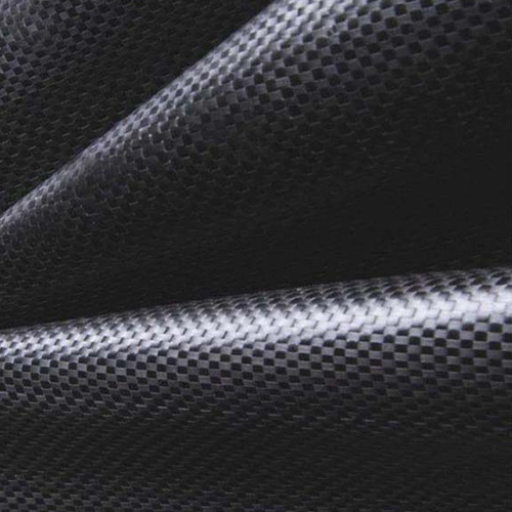

Woven Geotextiles are made by interlacing synthetic fibers, imparting them with high tensile strength and durability. These types of fabrics are best suited for applications requiring reinforcement and load distribution, such as road construction, retaining walls, and pavement stabilization. The interwoven filament structure allows minimum elongation, which in turn causes the deformation of any material placed above it under heavy loading pressure. One study, for example, reports that woven geotextiles have helped to improve soil stability and reduce rutting in unpaved roads by up to 50%. Due to their long service life, they become economically beneficial for projects with major structural requirements.

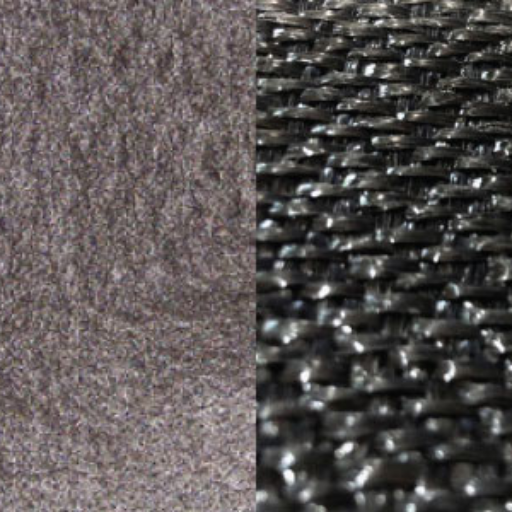

Non-Woven Geotextiles

Non-Woven geotextiles made through the action of needle punching or heat bonding of fibers are more flexible and permeable in nature. These geotextiles work well for filtration and separation as well as drainage. They allow water to pass through but retain fine soil particles. Non-woven geotextiles are applied in many areas, including erosion control, landfills, and landscaping. With the new advancements, hydrophilic coatings that can be applied to non-woven geotextiles may increase their permeability by as much as 30%, thereby enhancing their efficiency in stormwater management systems. At the same time, their degradability makes them a good environmentally conscious choice for temporary functions.

Both varieties of geotextiles are widely used in the construction of modern infrastructure, whereby each is designed to meet the needs of specific projects. Combining the benefits of these ingredients enables engineers and planners to create robust, sustainable solutions that satisfy performance and environmental criteria.

Woven Geotextile Fabrics

Woven geotextile fabrics are considered strong and strong-woven fabric material upon which polypropylene or polyester fibers are spun. Primarily, they treat soil stabilization, reinforcement, and separation in construction. It provides cases for a high-level load necessary with low elongation (for example, roadways, retaining walls, embankments). This ability of the fabric to restrain the mixing of soils and promote the dispersal of loads is truly essential to the durability and stability of infrastructure.

Features of Woven Geotextile

Woven geotextiles have excellent tensile strength and low elongation characteristics and are hence used for heavy-duty construction projects. Ranges can vary, usually within or above the range of 20 kN/m to 200 kN/m depending on the nature of application and type of materials used. Inherent strength allows the fabric to perform, for instance, in the environment of retaining walls or steep slopes, with high stress.

The other is that it has low permeability, which prevents the migration of fine soil particles while allowing water to permeate. Generally speaking, these textiles have an AOS (app parent opening size) ranging between 150 and 400 microns. Such a degree of filtration is sufficient to allow efficient stabilization of soil and sediment control.

Durability is yet another property of woven geotextiles. They maintain their function for several decades, even in hostile environments, due to resistance to UV rays, chemicals, and biological degradation. Also, the ability to disperse loads helps reduce settling and maintain expenses in infrastructure projects.

Another advantage of woven geotextiles is that they are economically beneficial. According to industry data, woven geotextiles are claimed to improve reinforcement and materials, reducing construction costs for a roadway by 30 percent. Woven geotextile in road construction essentially reduces aggregate thickness requirement since it lends added support to the structure.

Applications of woven geotextiles are growing continuous as improvements increase performance and compatibility with the environment. Then, the continued development and engineering have enabled their use in protecting erosion sites in coastal areas to the construction of highways with a heavy scale.

Advantages of Woven Geotextile Fabric

Woven geotextile fabrics greatly benefit civil engineering and construction projects through their durability, versatility, and cost-effectiveness. Woven geotextiles can support soil in their ability of load distribution and protection against erosion in adverse conditions. Research has shown that the use of woven geotextiles could halve aggregate thickness in road construction, considerably saving on materials and labor. When in drainage and filtration systems, their high tensile strength and permeability keep the water flowing, while preventing soil from migrating, thus ensuring long-term reliability for these systems.

The manufacturing improvements over recent years have led to greater environmental compatibility of woven geotextiles, with many now being made from recycled or biodegradable materials. For example, these eco-friendly variants allow for a lesser environmental impact in larger projects. It has been reported that geotextiles increase the life span of infrastructure by 25%, especially in highly trafficked areas or where infrastructure is exposed to adverse weather conditions. Their application in levee reinforcement, retaining walls, and underlay for railways also demonstrates their adaptability to diverse project requirements.

This is an essential factor in fostering coastal and riverbank protection with woven geotextiles. According to statistics from the industry, placing geotextiles on shorelines can reduce erosion rates by up to 30% over traditional means. These fabrics function as a barrier to soften wave action, allowing vegetation to grow, thereby encouraging sustainable ecosystems. The constant improvement in woven geotextiles ensures, in turn, that these remain a key factor in addressing modern infrastructure challenges efficiently and responsibly.

Typical Applications of Woven Geotextiles

The unique amalgamation of strength, permeability, and versatility has made Woven geotextiles dexterously applicable in various construction and infrastructure areas. One high-profile application is in the construction of highways as a separator and stabilizer. Recent data states that the application of geotextiles in stabilizing roadway subgrade will increase road life to 50%, thereby cutting down the frequency of repair and maintenance cost.

In drainage, they further provide filtration functions and prevent soil clogging in drainage pipes. Studies have found the incorporation of geotextiles in drainage systems able to improve water flow efficiency by some 20 percent as compared to traditional methods. Also, in retaining walls, woven geotextiles provide structural support by uniformly distributing loads, enabling the safe retention of soil in challenging terrain.

Environmental application remains significant. Woven geotextiles remain an important factor in controlling coastal erosion and protecting shorelines. Apart from contributing to the conservation of wildlife habitats, geotextiles experience erosion at reinforced sites by about 40% as compared to those that are non-reinforced. Coupled with their ability to support vegetation growth, they provide dual functionality in ecological conservation and infrastructure strengthening.

With material technology advancement, woven geotextiles continue to improve durability and efficiency, thereby establishing themselves as a key candidate for modern engineering and environmental challenges.

Non-Woven Geotextile Fabric

Non-woven geotextile fabric is a permeable synthetic material in which fibers are bonded together by chemical or heat processes. It is designed primarily for applications of filtration, separation, drainage, and protection in construction and landscaping. This type of geotextile helps prevent soil erosion with adequate filtration of water and ensures the durability of the base materials. Its versatility and easy installation have made it a dependable option for applications such as road construction, retaining walls, and erosion control measures.

Characteristics of Non-Woven Geotextiles

Non-woven geotextiles with their properties find great application in varied civil engineering and ecological projects. They are mostly manufactured from synthetic polymers like polypropylene or polyester that are subjected to needle-punching or thermal bonding processes. One distinguishing feature among them is the permeability, thus efficiently allowing water to pass through yet retaining soil particles. Industry standards specify a porosity in non-woven geotextiles between 70-90%, permitting efficient drainage and filtration in heavy-duty applications.

They may also be noted for their tensile value and resistance to environmental degradation. The strength range between 10 kN/m and 50 kN/m is one data-based estimate for an average non-woven geotextile, depending upon the treated product. The geotextile is chemically resistant and impervious to ultraviolet rays and biological degradation, so it would survive in harsh environments.

These are usually applied in situations where separation and stabilization are necessary, such as roads, railways, or coastal structures. A practical example is the road construction whereby, to some extent, these enhance pavement life by separating soil from fine and coarse aggregate, which can cause structural failures as time goes by. Studies show that when non-woven geotextiles are applied in road foundation, the life span of the road may be increased by 50%, which substantially lowers maintenance cost.

Further developments for non-woven geotextiles have been applied towards producing ecological variants with minimal environmental impact. These developments seek to marry the performance of conventional geotextiles with sustainable materials and processes in response to the demands for green infrastructure alternatives.

Advantages of Non-Woven Geotextile Fabric

A range of advantages are provided by these fabrics, making them indispensable for civil engineering and environmental projects. Because of their durability and versatility, the geotextiles perform well in separation, drainage, filtration, reinforcement, and protection applications. In this context, recent studies showed that non-woven geotextiles improve the drainage capacity of a soil system by up to 20 percent, hence preventing waterlogging and retaining the integrity of infrastructure projects.

Moreover, due to the high permeability of non-woven geotextiles, soil particles are actually filtered but fine soil particles are blocked from migrating. By stopping the process of erosion, these non-woven geotextiles can reduce erosion by up to 30%. In road construction, they reduce stresses on the underlying strata by evenly distributing the loads and thereby can extend the life of roads by many decades in areas that experience heavy traffic. Further, through today’s developing greener-tech processes, the current generation of eco-friendly non-woven geotextiles is increasingly employing recycled materials, which has led to a 40% reduction in emissions from manufacturing, thus supporting the drive of global sustainability.

They also offer the flexibility to confront a wide array of climates and terrains, from soft soil stabilization in wetlands to soil reinforcement along steep slopes in arid areas. In tandem with these developments, non-woven geotextiles continue to shape a key building block for sustainable construction, offering great savings in the longer run plus environmental benefits.

Typical Applications of Non-Woven Geotextiles

Non-woven geotextiles are commonly used in filtration, drainage, separation, reinforcement, and erosion control across various construction and environmental projects.

| Key Point | Details |

|---|---|

| Filtration | Prevent soil loss |

| Drainage | Manage water flow |

| Separation | Keep layers apart |

| Reinforcement | Add structural strength |

| Erosion Ctrl | Curb surface wear |

Key Differences Between Woven and Non-Woven Geotextiles

Key differences between woven and non-woven geotextiles mostly concern manufacturing processes and applications. Woven geotextiles achieve their high-strength quality by weaving the fibers together and thus they are greatly used in reinforcement and load-bearing projects. Non-woven geotextiles are made by bonding together the fibers to form the fabric application of filtration, drainage, and separation. I would hence have to select the appropriate type required for a specific project.

Structural Differences Between Woven and Non-Woven Geotextiles

Structural differences in woven and non-woven geotextiles arise because of the difference in manufacturing processes. Woven geotextiles are made by weaving individual yarns or fibers in a specified layout to make a highly structured material possessing great tensile strength. Based on recent data, woven geotextiles mostly show tensile strength values ranging from 200 kN/m to 500 kN/m, being thus suitable for soil reinforcement, road stabilization, and erosion control.

Contrastingly, non-woven geotextiles are manufactured through needle-punching or thermal bonding processes, among others. These processes create fabrics comprising randomly arranged fibers. This feature offers non-woven geotextiles flexibility and suitability for filtration and drainage, as they allow water to pass through while holding back soil particles. Recent advances have shown that, depending on the material type and density, non-woven geotextiles may achieve permeability anywhere in the range of 0.1 to 0.8 cm/sec.

Such differences need to be understood to choose the most effective geotextile for a given project. While the strength and durability of woven geotextiles make their heavy load applications feasible, non-woven geotextiles come to the fore when separation and filtration challenges are concerned.

Permeability and Filtration

Permeability and filtration characteristics greatly contribute to the performance of geotextiles in administering water flow and maintaining soil stability. According to the most recent data, the permeability value of woven geotextiles lies in a range from 0.001 to 0.1 cm/sec. It also makes them suitable for applications where water drainage is less important but where having a high tensile strength is necessary, such as in retaining walls and road construction.

Higher permeability values characterize non-woven geotextiles, usually varying from 0.1 to 0.8 cm/sec, and they consist of a porous structure that allows efficient flow of water. Recent studies on-site affirmed the use of non-woven geotextiles in drainage where it is vital to maintain water flow and prevent soil erosion. In highway constructions, for instance, non-woven materials are greatly appreciated for their separation and filtration properties, which slowly reduce the risk of contaminating the subgrade.

In the major advancements witnessed in the manufacturing of geotextiles is the incorporation of polymeric blends, which boost both permeability and filtration efficiency. According to published studies, advanced non-woven materials currently present a filtration opening size (FOS) ranging from 0.1 to 0.3 mm, which best fits applications for stormwater management systems and landfill engineering.

Understanding the above detailed parameters is vital to the proper selection of geotextiles to suit specific project needs. The incorporation of correct permeability data along with field-tested performance parameters will greatly aid engineers in designing more efficient and sustainable infrastructure solutions.

Cost Considerations

In analyzing the cost of geotextiles, various attributes assure market fluctuations in the final price: type of material, weight, and manufacturing process. Currently, for example, woven geotextiles are priced between $1.00-$2.00 per square yard, whereas non-woven varieties go from $0.50-$1.50 per square yard. Prices depend mostly on the suppliers, their location, and in most cases, in how much quantity was bought.

New research emphasizes the considerable cost reduction achieved by employing geotextiles in large-scale infrastructure endeavors. For instance, the construction of roads using geotextiles would save up to 30 percent on traditional base layer materials by reducing the thickness required for layers of aggregates. On the other hand, due to their durability and increased drainage, geotextiles sharply reduce maintenance costs as well, down by an estimated 20 percent in the long term.

It is this joint costing which, coupled with lifecycle revenues, which relates geotextiles almost directly to sustainable engineering and infrastructure development in terms of financing. However, the best planning instances might make a difference in achieving such results, so careful product selection would be required.

Pros and Cons of Woven vs Non-Woven Geotextile Fabrics

The woven fabrics develop very high strength and durability were preferentially considered in load applications such as road construction, stabilization, etc. Non-woven fabrics have a higher permeability than their woven counterparts and, therefore, are most apt for drainage and filtration. I would have selected them according to the situation: woven for strength and reinforcement and non-woven for drainage and separation.

Advantages of Woven Geotextiles

Woven geotextiles are made by weaving synthetic materials, predominantly polypropylene or polyester, into durable and tensile fabric. Woven geotextiles are, however, exceptionally strong and have a wide range of applications where high-strength functions are demanded. Woven geotextiles can have great tensile strength, which is in excess of 200 kN/m as per the industry standards and is, therefore, suitable for reinforcement applications like highways, railways, and retaining walls.

Due to their very low elongation upon loading, they offer a considerable degree of stability in applications where load distribution is required. They additionally possess great resistance to degradation from ultra-violet rays and chemicals, thereby ensuring high durability in harsh environmental conditions. Due to their low permeability, their use in water filtration procedures is limited. Woven geotextiles are, therefore, mostly deployed in projects requiring stabilization, reinforcement, and erosion control.

Disadvantages of Woven Geotextiles

There may be several drawbacks to woven geotextiles beside the strength and durability ones that should be carefully evaluated before adoption. One of the first disadvantages attributed to them is their limited permeability with respect to water. Recent data shows that the average coefficient of permeability of woven geotextiles ranges only between 10^-5 to 10^-7 cm/sec, which is very low compared to that of the non-woven ones. This makes them not so fit on the grounds for which drainage and filtration are amongst their primary concerns, real high flow water management systems.

Another more drawback is that woven geotextiles are usually much more expensive at the beginning. They generally require a more elaborate manufacturing process than those for non-woven, raising the price by about 20-30% compared to non-woven geotextiles. They can also be too rigid, which complicates installation, especially where terrain is complex or in situations requiring flexibility in adjustments.

In severe acidic or alkaline soil environments, their resistance to UV light and durability may suffer after heightened exposure. Changing pH values Somewhere in the extreme ranged (below 3 and above 10) for five years would reduce the tensile strength of woven geotextiles by 15-20%. In other words, selecting these materials for long-term applications requires careful consideration of environmental conditions.

Characteristics and Strengths of Non-Woven Geotextiles

These materials experienced the highest rate of development due to their adaptability and performance excellence in a multitude of applications. Main properties they offer include filtration, which can be considered most important for drainage and erosion control. They also are very puncture-resistant and tear-resistant when applied in uneven conditions. New data states that when compared to woven geotextiles, their water permeability is higher, and efficient water flow is essential in subsoil drainage systems.

However, there are a few limitations to non-woven geotextiles. Despite their success in filtration and drainage, they may not provide as much tensile strength as the woven counterparts. According to case studies, non-woven geotextiles could lose up to 10% of their strength in three years when exposed to heavy loads and harsh environments. Furthermore, they will have less resistance to UV degradation under prolonged exposures to sunlight, so they must be treated and applied with care.

For these reasons, non-woven geotextiles are preferably used in places where filtration and drainage should be optimized at the least load-bearing strength. Conducting thorough site assessments with intelligent choices in materials will help optimize their performance.

Reference sources

1. Influence of Non-Woven Geotextile Over Chemically Stabilized Soil in Controlling Erosion (Varsha & Jeyapriya, 2023)

-

- Key Findings:

- The erosion rate decreased with the use of geotextile on chemically stabilized soil with Magnesium Stearate when compared to soil stabilized with Guar gum powder.

- For rainfall intensities of 60mm/hr and 70mm/hr, the erosion rates were 1950g/m²/hr and 2312g/m²/hr respectively for the Magnesium Stearate stabilized soil with geotextile.

- Methodology:

- Erosion tests were conducted on a slope model with an inclination of 20° using non-woven geotextile over chemically stabilized soil (with Guar gum powder and Magnesium Stearate).

- The erosion rates were measured for maximum hourly rainfall intensities of 60mm/hr and 70mm/hr.

- Key Findings:

2. Bioderived Antibacterial Coating for Polypropylene Non-woven Fabric to Prevent Secondary Infection (S et al., 2024, pp. 1–9)

-

- Key Findings:

- The chitosan/CNF/nanocurcumin-coated non-woven PP fabric enhanced the antibacterial activity of the PP fabric without compromising its hydrophobicity.

- Methodology:

- A non-woven polypropylene (PP) fabric was coated with a bioderived antibacterial coating containing chitosan, cellulose nanofibers (CNF), and nanocurcumin.

- The antibacterial properties of the coated non-woven fabric were evaluated.

- Key Findings:

3. Influence of the Non-Woven Geotextile (NWG) on the engineering properties of clayey-sand treated with copper slag-based geopolymer (Fakhrabadi et al., 2021)

-

- Key Findings:

- The use of non-woven geotextile as reinforcement improved the bearing capacity of the soil.

- Methodology:

- The bearing capacity of rigid footings constructed on sand reinforced with non-woven geotextile was investigated through laboratory model tests.

- Parameters such as the location of the upper layer of geotextile, number of geotextile layers, width of reinforcement, and vertical spacing between layers were varied.

- Key Findings:

Frequently Asked Questions (FAQs)

What distinguishes woven geotextile fabrics from nonwoven ones?

Well, essentially the differences with a fabric of this type are in their manufacturing methods and their properties. Woven geotextiles are those where threads are interlaced, generally producing a much stronger fabric that prefers projects where strength and stability are in demand. In contrast, nonwoven geotextiles bond the fibers one to another, thereby granting them higher permeability and flexibility. This makes it more suitable for drainage and erosion control projects.

How do you choose between woven and nonwoven geotextile fabrics?

The selection between woven and nonwoven geotextile fabric depends on the requirements of your project. When heavy loads require a strong reinforcement and stabilization, woven geotextiles are generally the right choice; however, if your application requires drainage or filtration and permeability of utmost importance, great performances will be delivered by nonwoven geotextiles. So consider the conditions and the proposed uses.

Where are woven geotextiles applied?

Woven geotextiles are used for separation and reinforcement in applications such as driveway construction, road works, and retaining walls. Due to their durability and ability to absorb loads from heavy machinery or earthworks, they find application in many jobs. They may also stabilize soil to control erosion from surface runoff.

What is a nonwoven geotextile made of?

A typical nonwoven geotextile is made from a range of synthetic fibers such as polyester or polypropylene. Fibers are bonded together by mechanical means, thermal means, or chemical means to produce a fabric that is lightweight yet robust for drainage and filtration. The construction allows for good water flow but limits soil loss, thus perfect for landscaping and erosion control.

What are the major differences between woven and nonwoven geotextiles?

Major differences between woven and nonwoven geotextiles are composition, strength, permeability, and application. Woven geotextiles are strong and durable for high-stress environments whereas nonwoven geotextiles are veined for drainage facilities and flexibility. Considering these differences is extremely crucial when choosing the right geotextile for your project.

For drainage projects, would woven geotextile be used?

Woven geotextiles may be suitable for drainage projects, given that their design satisfies drainage requirements in question. They provide very good separation and reinforcement but might not be as permeable as nonwovens. Where huge volumes of water flow or where filtration is necessary, the nonwoven options are more recommendable.

When should I consider the right geotextile for my project?

Consider soil types, load requirements, drainage needs, and environmental conditions when choosing the proper geotextile for your project. You must gauge if your application requires woven or nonwoven, which may be erosion, separation, or filtration; the right answer will give you the best performance.

What types of landscape fabric exist?

Numerous types of landscape fabrics exist, including woven, nonwoven, and biodegradable. Woven landscape fabrics tend to be strong and durable, great for suppressing weeds and letting water through. Nonwoven fabrics provide water drainage and erosion control, and biodegradable fabrics provide an eco-friendly option, breaking down after use.